Method for preparing gel breaker for treating waste drilling fluid

A technology of waste drilling fluid and gel breaker, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as economic burden, environmental hazards, failure to meet environmental protection standards for emissions, complicated preparation process, etc., to increase transparency and cleanliness , The preparation process is clear and controllable, and the effect of good stability at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a method for preparing a gel breaker for treating waste drilling fluid. The preparation method has smooth flow, easy control of preparation parameters, low pollution and high yield.

[0021] Embodiments of the present invention will be described in detail below in conjunction with the following drawings.

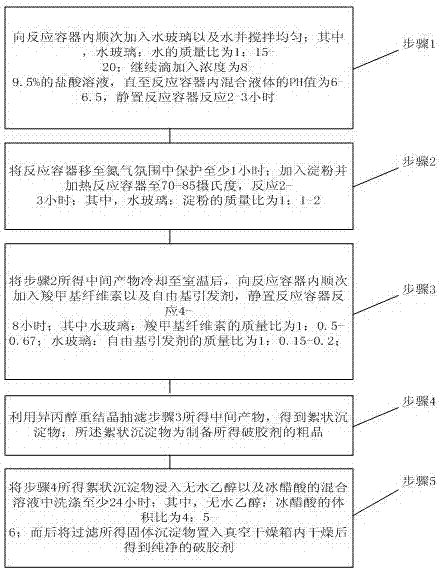

[0022] Such as figure 1 As shown, a kind of method for preparing the breaker of waste drilling fluid provided by the invention comprises the following steps:

[0023] Step 1: Add water glass and water to the reaction vessel in sequence and stir evenly; among them, the mass ratio of water glass: water is 1:15-20 (water glass is CP grade); continue to add dropwise at a concentration of 8-9.5% Hydrochloric acid solution, until the pH value of the mixed liquid in the reaction vessel is 6-6.5, leave the reaction vessel to react for 2-3 hours;

[0024] Specifically, the nano-silica colloidal dispersion liquid is prepared in the reaction vessel throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com