Flexible early strength concrete and preparation method thereof

A concrete and flexible technology, applied in the field of flexible early-strength concrete and its preparation, can solve the problems of increased wear, rapid decay of the anti-slip performance of cement concrete pavement, and difficulty in large-scale application of concrete technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

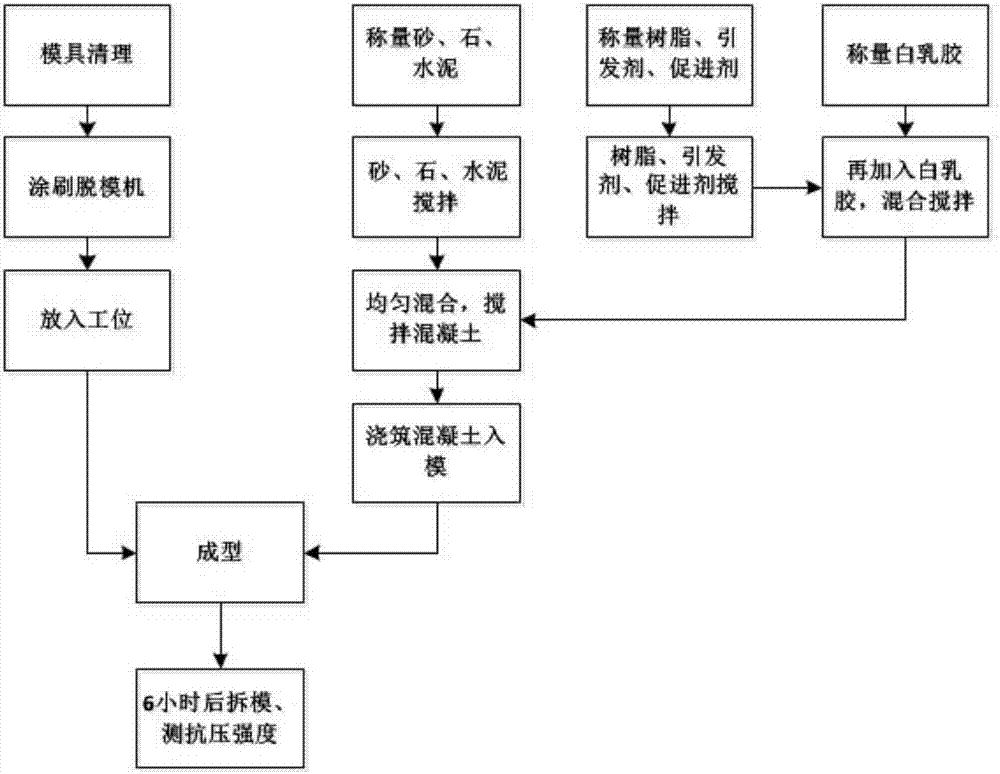

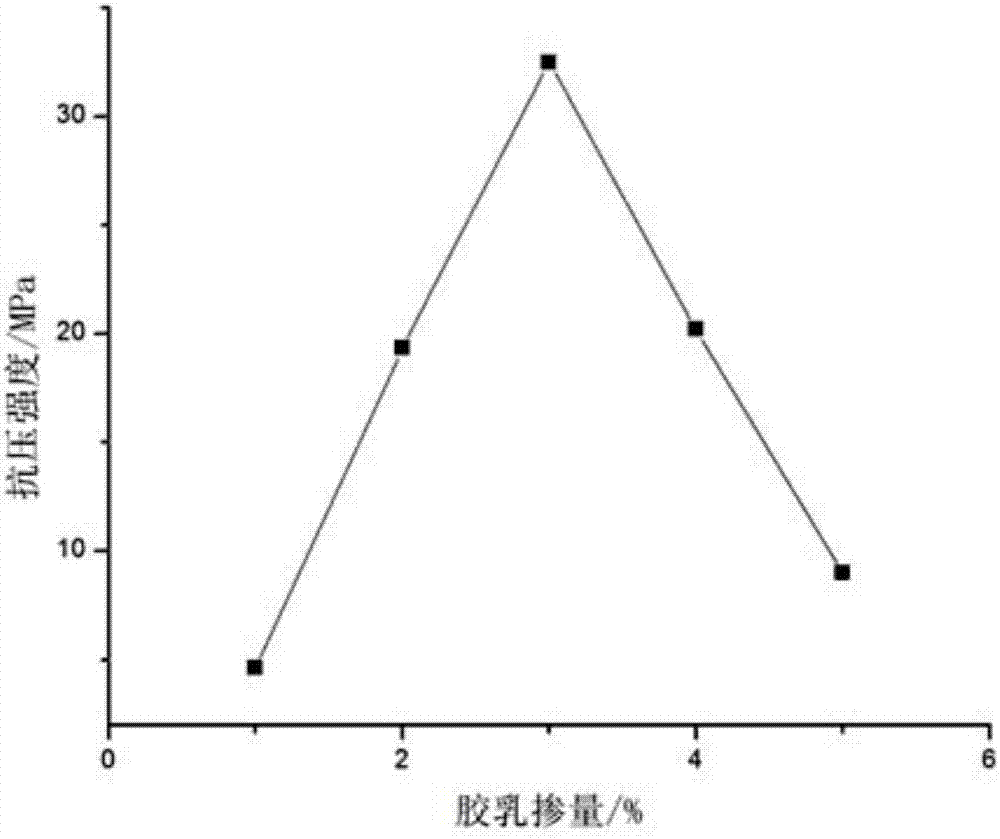

[0045] A flexible early-strength concrete, such as figure 1 Shown, concrete components according to the amount (kg / m 3) is calculated as follows: cement 190kg, machine-made sand 853kg, gravel 1043kg, unsaturated polyester 316kg, initiator 13kg, accelerator 13kg, white latex 3kg. After the materials are ready, follow the steps below:

[0046] The first step: clean the inside and outside of the mold, and apply the release agent;

[0047] Step 2: Put sand, gravel, and cement into the iron basin in order of feeding from coarse to fine, and stir for 60 seconds until uniform;

[0048] The third step: at the same time as the second step, first add the initiator to the resin, stir evenly, then add the accelerator, stir evenly; then add the white latex to the resin, stir evenly;

[0049] Step 4: Add the resin mixture into the iron basin and stir for 60 seconds to obtain a flexible early-strength concrete of the present invention;

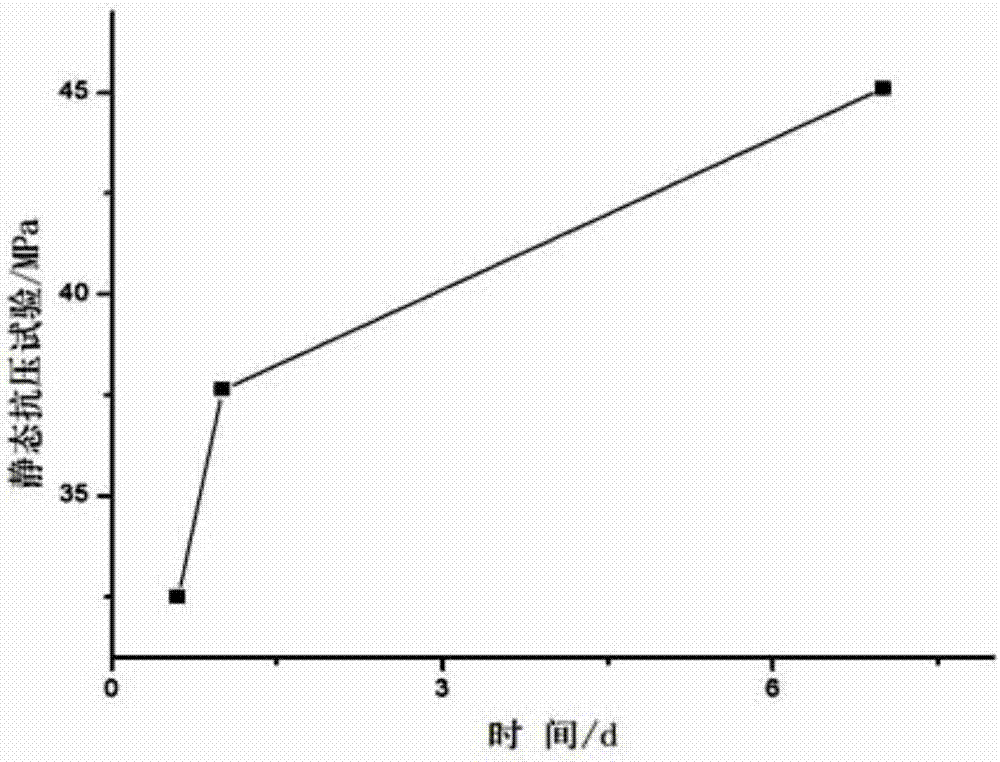

[0050] Step 5: Pour concrete into the treated mold...

Embodiment 2

[0056] A flexible early-strength concrete, such as figure 1 Shown, concrete components according to the amount (kg / m 3 ) is calculated as follows: cement 190kg, machine-made sand 853kg, gravel 1043kg, unsaturated polyester 316kg, initiator 13kg, accelerator 13kg, white latex 6kg. After the materials are ready, follow the steps below:

[0057] The first step: clean the inside and outside of the mold, and apply the release agent;

[0058] Step 2: Put sand, gravel, and cement into the iron basin in order of feeding from coarse to fine, and stir for 60 seconds until uniform;

[0059] The third step: at the same time as the second step, first add the initiator to the resin, stir evenly, then add the accelerator, stir evenly; then add the white latex to the resin, stir evenly;

[0060] Step 4: Add the resin mixture into the iron basin and stir for 60 seconds to obtain a flexible early-strength concrete of the present invention;

[0061] Step 5: Pour concrete into the treated mol...

Embodiment 3

[0067] A flexible early-strength concrete, such as figure 1 Shown, concrete components according to the amount (kg / m 3 ) is calculated as follows: cement 190kg, machine-made sand 853kg, gravel 1043kg, unsaturated polyester 316kg, initiator 13kg, accelerator 13kg, white latex 9kg. After the materials are ready, follow the steps below:

[0068] The first step: clean the inside and outside of the mold, and apply the release agent;

[0069] Step 2: Put sand, gravel, and cement into the iron basin in order of feeding from coarse to fine, and stir for 60 seconds until uniform;

[0070] The third step: at the same time as the second step, first add the initiator to the resin, stir evenly, then add the accelerator, stir evenly; then add the white latex to the resin, stir evenly;

[0071] Step 4: Add the resin mixture into the iron basin and stir for 60 seconds to obtain a flexible early-strength concrete of the present invention;

[0072] Step 5: Pour concrete into the treated mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com