A kind of semi-opening double-core casing for reaction spraying in granulation of compound fertilizer by acid method

A compound fertilizer, semi-opening technology, applied in the direction of ammonia compound, ammonium salt fertilizer, fertilizer mixture, etc., to achieve the effect of improving product quality, slowing down the degree of violent reaction, and reducing environmental pollution in workshops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

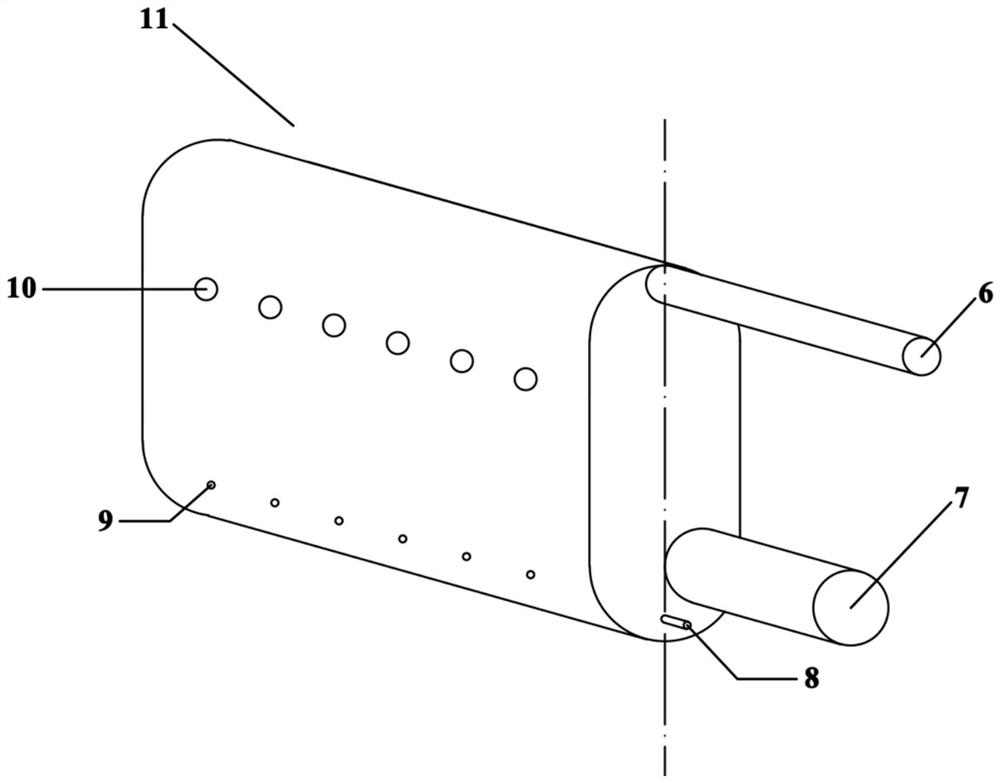

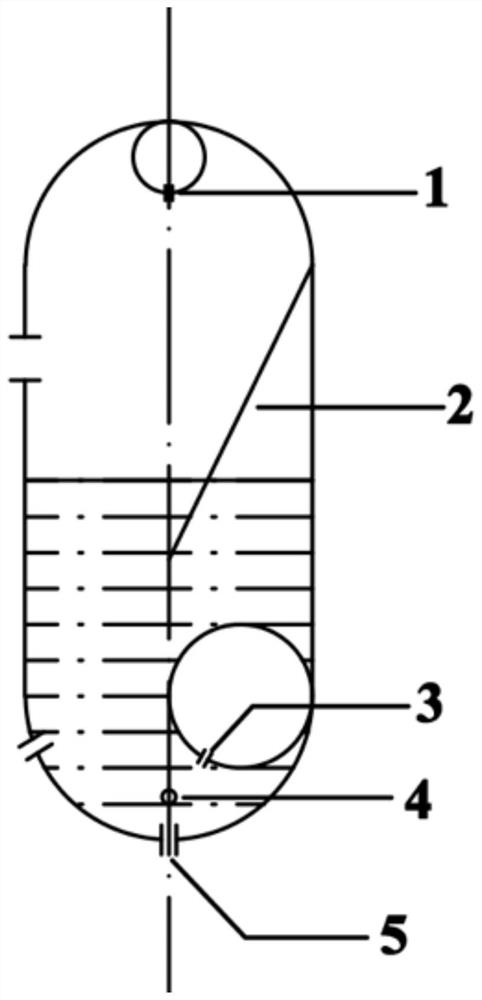

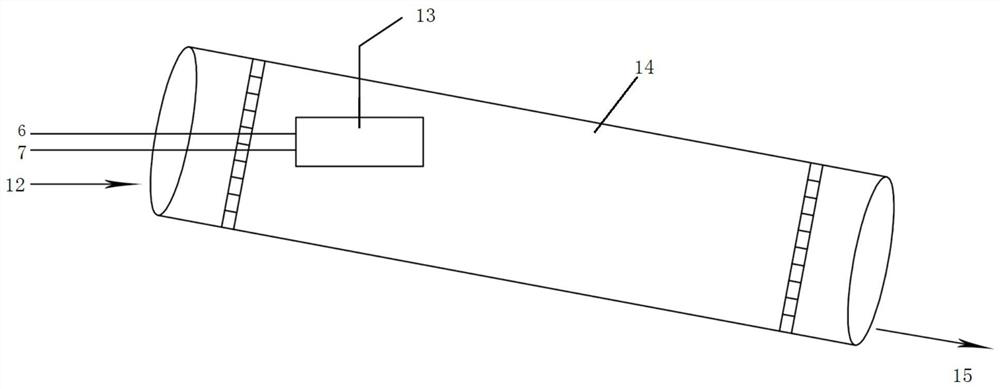

[0025] Such as Figure 1~2 As shown, a semi-open hole double-core sleeve used for reaction spraying in the compound fertilizer granulation by the acid method comprises a flat cylindrical reactor shell 11, a sulfuric acid tube 6 and an ammonia tube 7 arranged in parallel in the reactor, and a set The baffle above the ammonia pipe 7, such as image 3 As shown, the semi-perforated double-core casing 13 is placed horizontally in the drum 14 drum granulation drum.

[0026] Both ends of the oblate cylindrical reactor shell 11 are closed, and the column body is provided with three rows of holes: discharge nozzle holes 5 at the bottom, discharge nozzle holes 9 at the bottom of the side and overflow holes 10 at the top of the side, so that the reaction product can be sprayed evenly, which is beneficial to Material granulation. The sulfuric acid pipe 6 is positioned above the ammonia pipe 7, and the diameter of the sulfuric acid pipe 6 is smaller than the diameter of the ammonia pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com