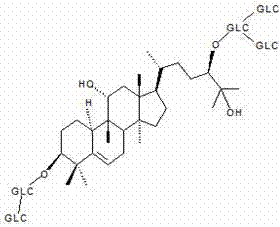

Method for simultaneously extracting Mogroside V and VI and 11-O-based glucoside V

A mogroside and base glycoside technology, applied in chemical instruments and methods, glycoside steroids, steroids, etc., can solve the problem of obtaining high-purity glycoside products, separation and purification of Luo Han Guo 11-O base glycoside V and glycoside VI There are few reports and other problems, to achieve the effect of improving utilization, increasing added value, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037](1) n-butanol extraction: Dissolve 100g of the refined mother liquor of mogroside V in 500g of water, add 500g of n-butanol for extraction, separate the water layer to obtain the n-butanol layer;

[0038] (2) Concentration and crystallization: Concentrate the n-butanol layer obtained in step (1) under reduced pressure at 80°C and a vacuum of -0.07MPa until the mass concentration of the concentrated solution is 25%, cool it at 15°C, and rotate at 120r / min, stirred and crystallized for 12h, filtered to obtain crystals and n-butanol crystallization mother liquor, dried the crystals to obtain 18.2g mogroside VI;

[0039] (3) Polyamide chromatography: Concentrate the n-butanol crystallization mother liquor obtained in step (2) at 80°C and a vacuum of -0.07MPa to no alcohol under reduced pressure, and dissolve 70g of the obtained concentrate in 1750g of water. The flow rate of 1BV / h passes through the polyamide chromatography column (among them, the amount of polyamide used i...

Embodiment 2

[0043] (1) n-butanol extraction: Dissolve 200g of the refined mother liquor of mogroside V in 1600g of water, add 2400g of n-butanol for extraction, separate the water layer to obtain the n-butanol layer;

[0044] (2) Concentration and crystallization: Concentrate the n-butanol layer obtained in step (1) under reduced pressure at 85°C and a vacuum of -0.08MPa until the mass concentration of the concentrated solution is 30%, cool it at 30°C, and rotate at 80r / min, stirred and crystallized for 36h, filtered to obtain crystals and n-butanol crystallization mother liquor, dried the crystals to obtain 34.3g mogroside VI;

[0045] (3) Polyamide chromatography: The n-butanol crystallization mother liquor obtained in step (2) was concentrated under reduced pressure to no alcohol at 85°C and a vacuum of -0.08MPa, and 135g of the obtained concentrate was dissolved in 2700g of water, and then Pass through the polyamide chromatography column at a flow rate of 0.5BV / h (the amount of polya...

Embodiment 3

[0049] (1) n-butanol extraction: Dissolve 150g of the refined mother liquor of mogroside V in 900g of water, add 900g of n-butanol for extraction, separate the water layer to obtain the n-butanol layer;

[0050] (2) Concentration and crystallization: Concentrate the n-butanol layer obtained in step (1) under reduced pressure at 75°C and a vacuum of -0.06MPa until the mass concentration of the concentrated solution is 30%, cool it at 25°C, and rotate at a speed of 60r Stir and crystallize for 24 hours at a temperature of 1 / min, filter to obtain crystals and n-butanol crystallization mother liquor, dry the crystals to obtain 25.8g mogroside VI;

[0051] (3) Polyamide chromatography: The n-butanol crystallization mother liquor obtained in step (2) was concentrated under reduced pressure to no alcohol at 75°C and a vacuum degree of -0.06MPa, and 100g of the obtained concentrate was dissolved in 2000g of water to Pass through the polyamide chromatography column at a flow rate of 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com