Multifunctional double-lamp filament ion source

A multi-functional, ion source technology, applied in discharge tubes, electrical components, circuits, etc., can solve problems such as incompatibility of structure, high cost, complex ion source structure and control system, etc., to reduce system complexity, simplify control and The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

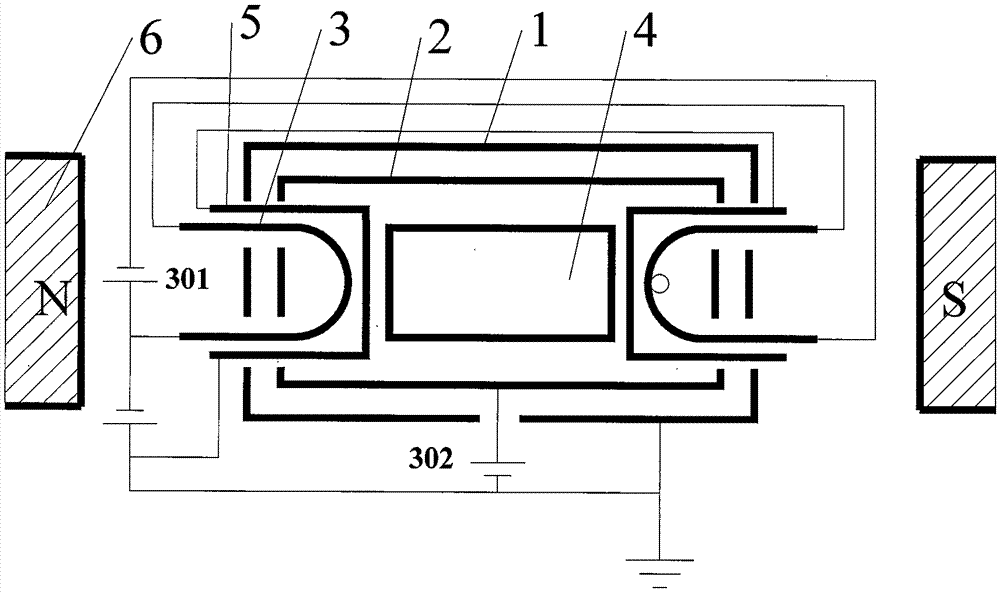

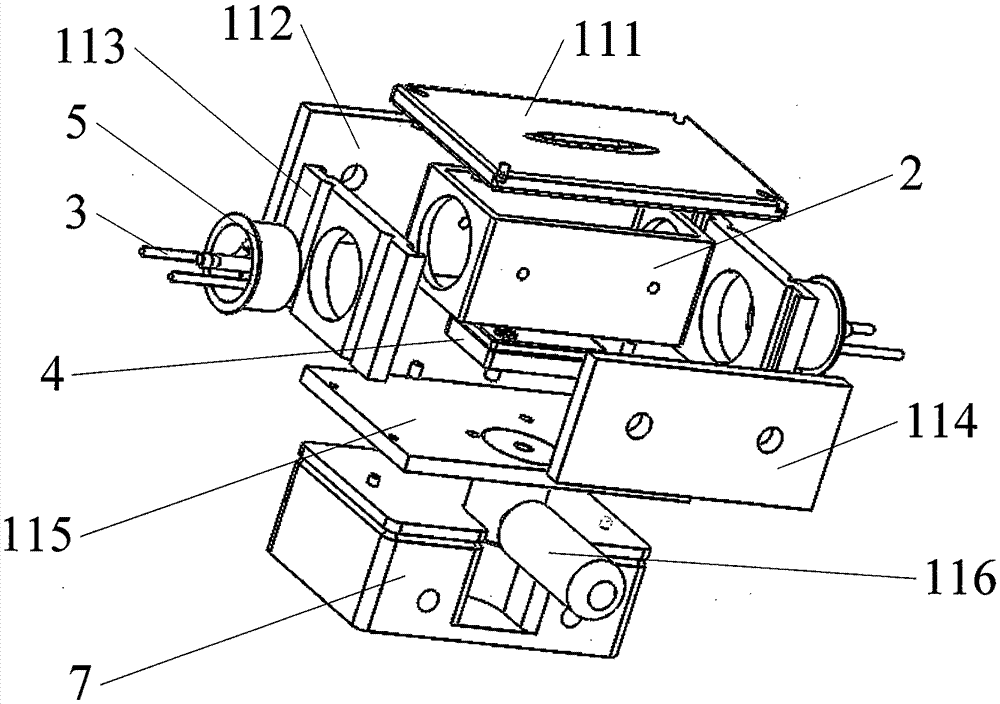

[0017] As shown in Figure 2, an embodiment of the present invention comprises an arc chamber cavity 1; the arc chamber cavity 1 comprises an arc chamber lead-out plate (111) and an arc chamber bottom plate 115; the arc chamber lead-out plate 111 lower surface, the arc chamber The four sides of the upper surface of the chamber bottom plate 115 are respectively connected to the first arc chamber side plate 112, the two hot cathode end side plates 113, and the second arc chamber side plate 114, and the two hot cathode end side plates 113 are opposite to each other; The bottom of the arc chamber bottom plate 115 is connected with the water cooling plate 7; the arc chamber bottom plate 115 can be connected with the first arc chamber side plate 112, the two hot cathode end side plates 113, and the second arc chamber side plate 114 through cylindrical pins. The arc chamber cavity can be a cuboid, but not limited to this shape.

[0018] The anode cylinder 2 is installed in the arc cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com