Automatic assembly production line for small household appliances

An automatic assembly and production line technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of product rework, slow production speed, low efficiency, etc., to improve market competitiveness, high work efficiency, and improved compactness type effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

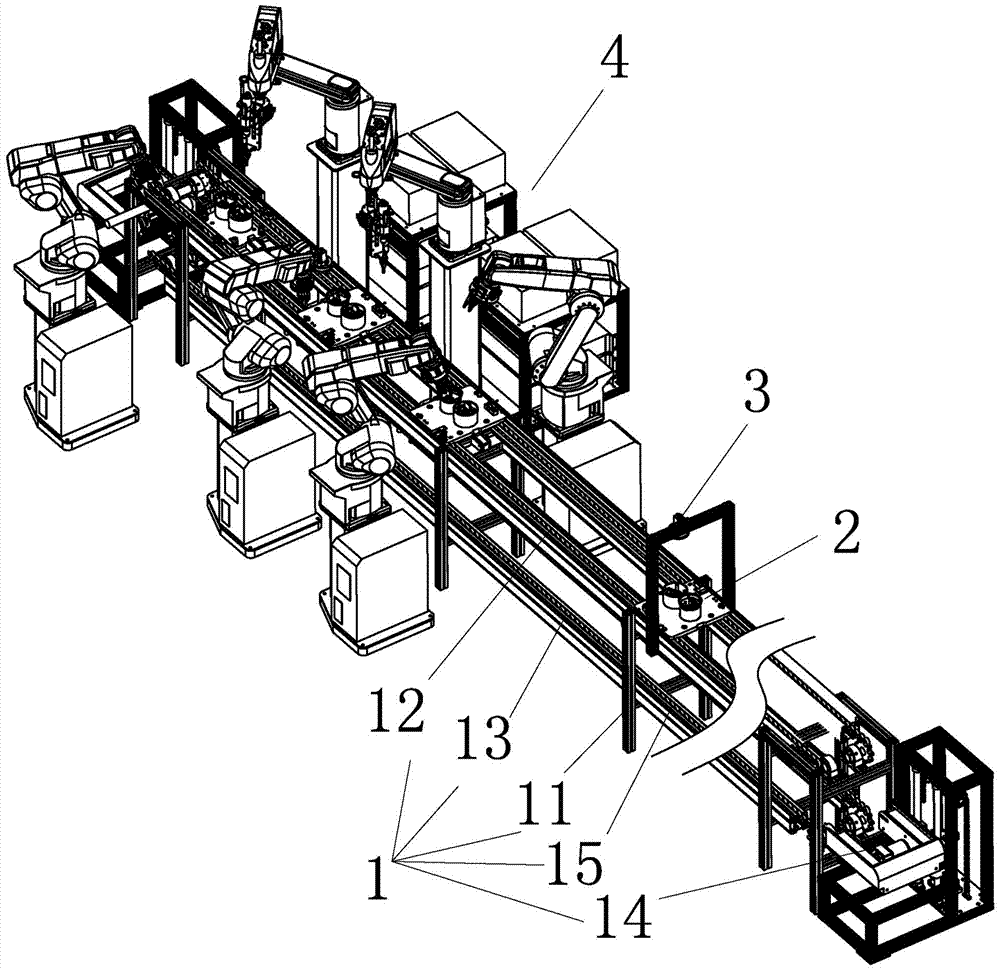

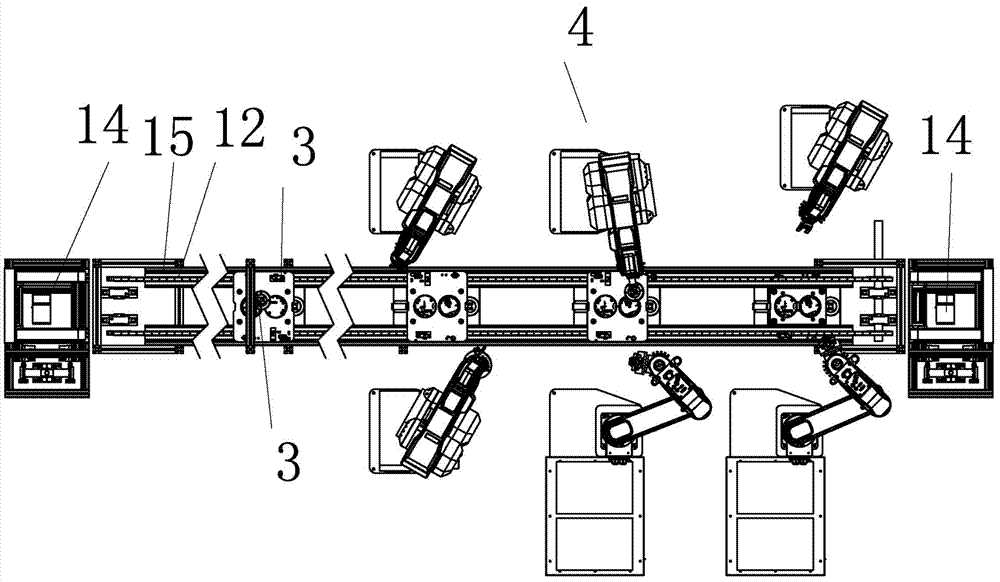

[0017] The present invention will be specifically and further described below in conjunction with the accompanying drawings. An automatic assembly line for small household appliances, characterized in that it includes a feeding machine table 1, a tooling board 2, a visual inspection system 3 and an accessory assembly system 4;

[0018] Wherein, the described feeding mechanical platform 1 comprises a main frame 11 and an upper conveying line 12 and a lower conveying line 13 arranged thereon, and lifters 14 are arranged at both ends of the main frame 11 to connect the upper and lower conveying lines 12, 13, A guide rail 15 is arranged above the top of the main frame 11, and the tooling plate 2 is installed in the guide rail, and is driven by the conveying line to move in the guide rail;

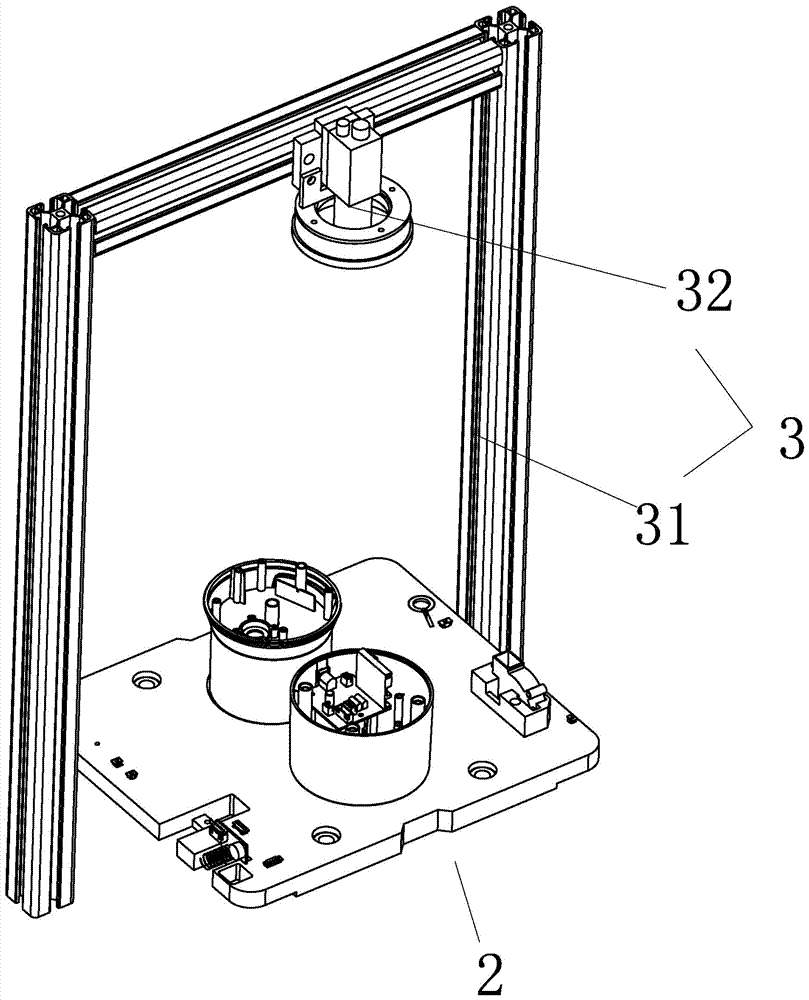

[0019] The tooling board 2 includes a main board body 21 and several positioning seats arranged on it, and product parts are placed in the corresponding positioning seats and fixed;

[0020] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com