Integrated wind speed and direction measurement device and method for windmill cabin

A technology of wind speed, wind direction and measuring device, which is applied in measuring device, fluid speed measurement, speed/acceleration/impact measurement, etc. It can solve the problems of different signals, reduced accuracy and life, and reduced sampling frequency, etc., and achieves high data sampling rate , high service life and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

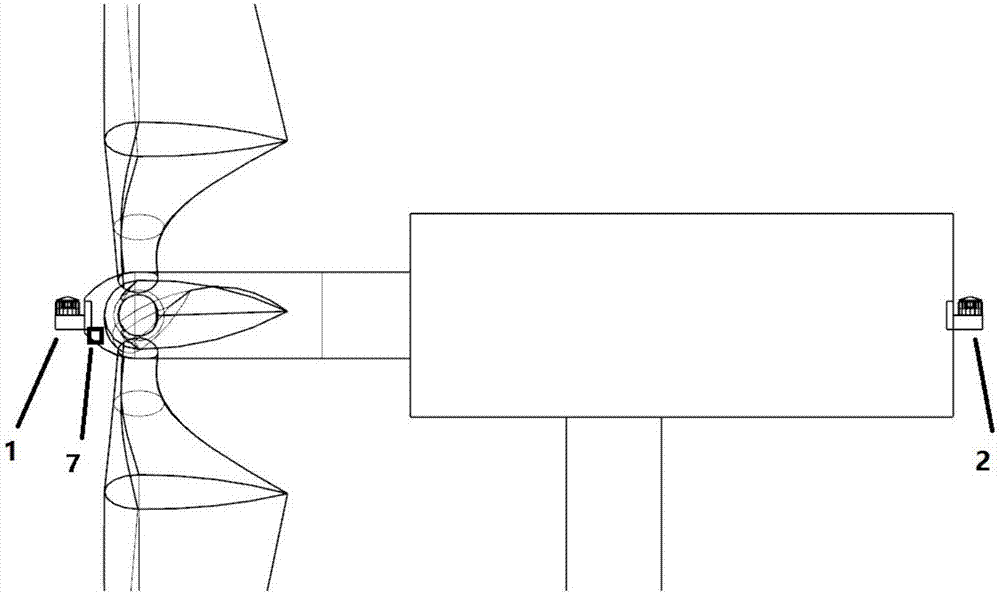

[0030] Embodiment 1: as figure 1 Shown is the overall layout of the wind turbine nacelle integrated wind speed and direction measuring device of the present invention. The installation process of the device is mainly as follows:

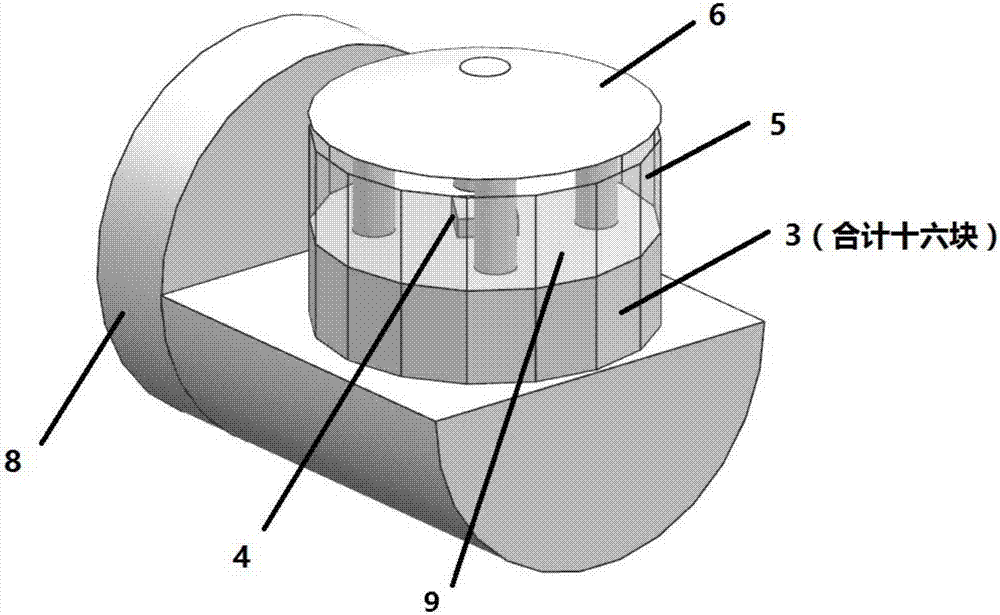

[0031] 1) Installation of wind measurement group 1 at the front edge of the hub. A hole is made at the center of the hub of the wind turbine nacelle, and the diameter of the hole is larger than the disc base 8, and the specific size depends on the required radial bearing. The center of the hole needs to be strictly aligned with the center of rotation of the hub. The roughness of the mating surfaces between the disc base 8 and the radial bearing is required to be above 3.2-6.3 μm. The anemometer group at the front edge of the hub is a fixed part and does not rotate with the hub of the cabin.

[0032] 2) Installation of wind measuring group 2 at the tail of the nacelle. A hole is opened in the middle of the tail plane of the wind turbine nacelle, ...

Embodiment 4

[0034]The relationship between embodiment 4 and embodiment 2 and embodiment 3 is the relationship between the whole and the part: the wind turbine nacelle integrated wind speed and direction measurement device firstly uses each velocity component measurement substrate 3 in embodiment 2 to measure and obtain the The magnitude of the wind pressure corresponding to the normal direction of the plate, and obtain the corresponding atmospheric pressure and temperature at this time through the embodiment 3, and finally according to the embodiment 4, the data of the embodiments 2 and 3 are analyzed and merged into the final vector wind speed. The specific steps of each embodiment are as follows.

Embodiment 2

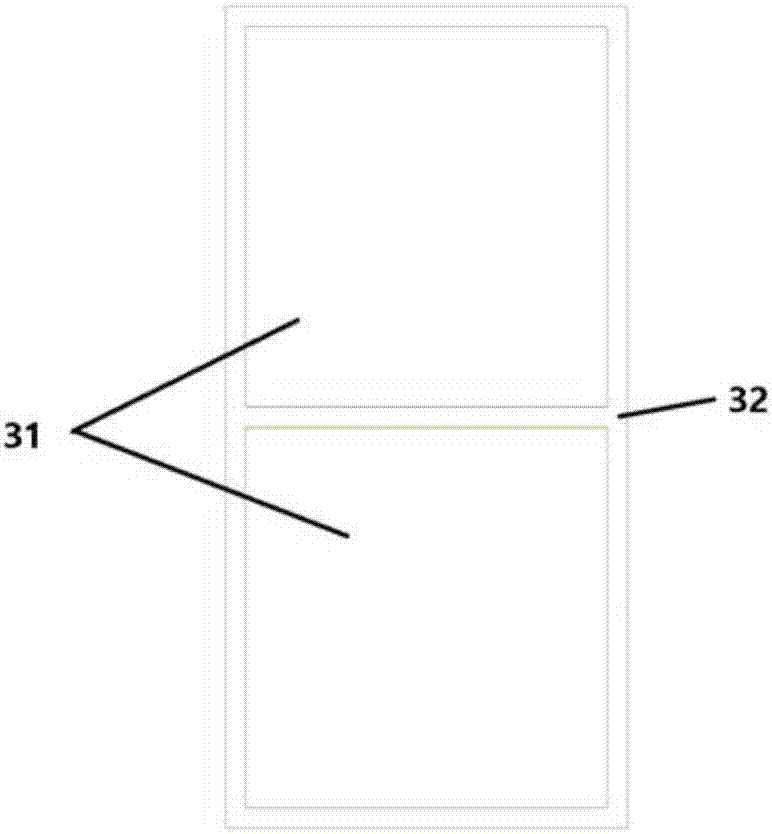

[0035] Example 2: Figure 3a and Figure 3b Shown is a schematic structural view of the velocity component measurement substrate of the present invention. The principle of signal measurement and calibration for each substrate is as follows:

[0036] The quantity of the piezoelectric ceramic sheets 31 of the velocity component measurement substrate 3 is n (n is an even number):

[0037] 1) Collecting signals: the piezoelectric ceramic sheet 31 collects voltage signals, and the voltage signals are arranged as P1, ..., Pn in ascending order, and the unit is V;

[0038] 2) Signal transmission: the signals of P1,...,Pn are filtered and amplified by the integrated circuit 71, and transmitted to the processor 73 by the internal I / O bus 72;

[0039] 3) A single velocity component measures the signal self-inspection of the substrate 3 and judges which piezoelectric ceramic sheet 31 fails and needs to be shielded: the criterion for judging is whether the measurement error between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com