Modified starch plant capsule and preparation method thereof

A technology of vegetable capsules and modified starch, applied in the field of medical excipients, can solve the problems of unstable quality, poor uniformity, poor film toughness and brittleness, etc., and achieve the effects of convenient operation, improved stability, and improved retrogradation and aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

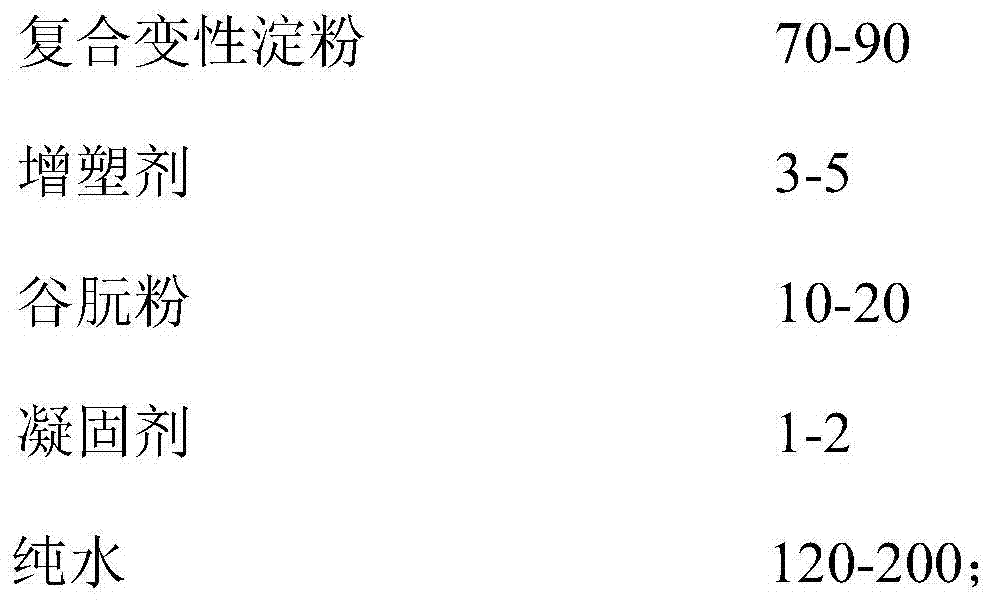

[0038] Modified starch vegetable capsule of the present invention is made from the raw material of following mass parts:

[0039]

[0040] Wherein, the composite modified starch is oxidized cross-linked hydroxypropyl pregelatinized quaternary composite modified starch.

[0041] Described plasticizer is glycerol.

[0042] Described coagulant is sodium stearate.

[0043] The preparation method of described composite modified starch is as follows:

[0044] (1) Add 62 parts by mass of deionized water, 5.7 parts by mass of expansion inhibitor, 0.35 parts by mass of catalyst sodium hydroxide, and starch of 38 parts by mass in the stirring reaction tank, stir and mix evenly;

[0045] (2) heating up to 35° C., adding 3.8 parts by mass of propylene oxide to react for 14 hours, and adding 0.04 parts by mass of a crosslinking agent to carry out crosslinking reaction for 1 hour;

[0046] (3) Heat up to 55°C, add 5% hydrochloric acid to adjust the pH to 7.0, add 0.04 parts by mass of...

Embodiment 2

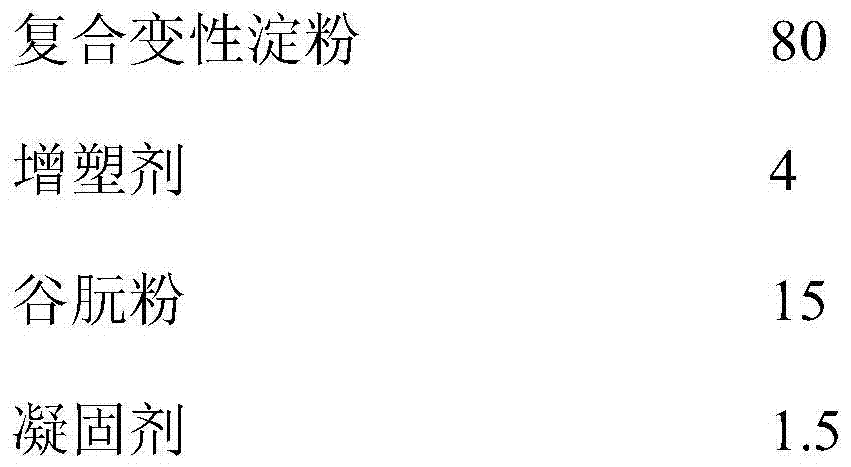

[0059] Modified starch vegetable capsule of the present invention is made from the raw material of following mass parts:

[0060]

[0061] Wherein, the composite modified starch is oxidized cross-linked hydroxypropyl pregelatinized quaternary composite modified starch.

[0062] Described plasticizer is polyethylene glycol.

[0063] The coagulant is xanthan gum.

[0064] The preparation method of described composite modified starch is as follows:

[0065] (1) Add 65 parts by mass of deionized water, 4.5 parts by mass of expansion inhibitor, 0.46 parts by mass of catalyst sodium hydroxide, and starch of 35 parts by mass in the stirring reaction tank, stir and mix evenly;

[0066] (2) heating up to 42°C, adding 1.75 parts by mass of propylene oxide to react for 17 hours, adding 0.1 parts by mass of a cross-linking agent to carry out cross-linking reaction for 3 hours;

[0067] (3) Heat up to 50°C, add 5% hydrochloric acid to adjust the pH to 7.5, add 0.03 parts by mass of cat...

Embodiment 3

[0080] Modified starch vegetable capsule of the present invention is made from the raw material of following mass parts:

[0081]

[0082] Wherein, the composite modified starch is oxidized cross-linked hydroxypropyl pregelatinized quaternary composite modified starch.

[0083] Described plasticizer is PVA and sorbitol.

[0084] Described coagulant is carrageenan and carboxymethyl starch.

[0085] The preparation method of described composite modified starch is as follows:

[0086] (1) Add 64 parts by mass of deionized water, 5.0 parts by mass of expansion inhibitor, 0.4 part of catalyst sodium hydroxide, and 37 parts by mass of starch in the stirring reaction tank, and stir and mix evenly;

[0087] (2) Warm up to 39°C, add 2.5 parts by mass of propylene oxide to react for 16 hours, add 0.06 parts by mass of crosslinking agent to carry out crosslinking reaction for 2 hours;

[0088] (3) Heat up to 53°C, add 5% hydrochloric acid to adjust the pH to 7.2, add 0.035 parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com