Waste gas treatment method

A waste gas treatment and waste gas technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of difficult wastewater treatment and large consumption of washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

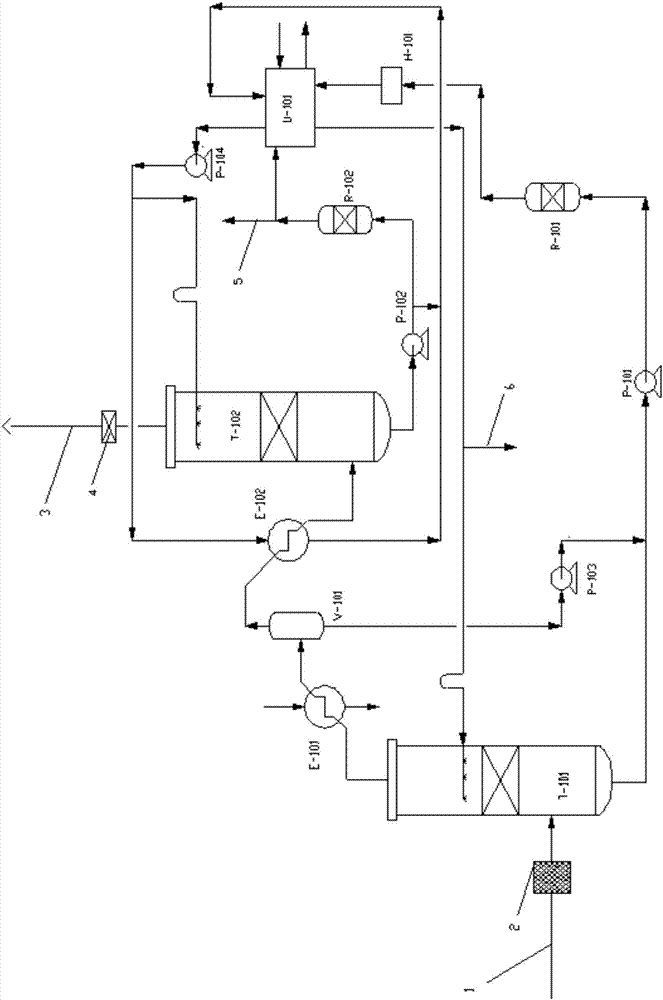

[0025] Such as figure 1 As shown in the process flow, the temperature of waste gas containing EO / PO is 120°C, and the flow rate is 924.954kg / h (N 2 =88.18wt%, EO=0wt%, PO=11.82wt%) are washed through a single-effect exhaust gas absorption tower T-101 (19 theoretical plates), and the washing water is 30t / h (H 2 O=70wt%, EG=30wt%, PG=0wt%), the exhaust gas at the top of the tower enters the first-effect cooler E-101 after being absorbed, and is cooled to 45°C with circulating water, and the cooled material enters the liquid separation tank V-101 for separation , the tank top gas phase enters the second-effect cooler and is cooled to 15°C with chilled water, and then enters the second-effect waste gas absorption tower T-102 (19 theoretical plates) for secondary washing, and the secondary washing water is alcohol-containing wastewater at 10°C 4.560t / h(H 2 O=70wt%, EG=30wt%, PG=0wt%), the EO content in the gas phase after washing is 0PPM respectively, and the PO content is 1PPM, ...

Embodiment 2

[0028] Such as figure 1 As shown in the process flow, the temperature of waste gas containing EO / PO is 120°C, and the flow rate is 969.646kg / h (N 2 =71.3wt%, EO=28.7wt%, PO=0wt%) are washed by a single-effect exhaust gas absorption tower T-101 (theoretical plate number 19), and the washing water is 70 ℃ alcoholic waste water 30t / h (H 2 O=70wt%, EG=30wt%, PG=wt%), the exhaust gas at the top of the tower enters the first-effect cooler E-101 after being absorbed, and is cooled to 45°C with circulating water, and the cooled material enters the liquid separation tank V-101 for separation , the tank top gas phase enters the second-effect cooler and is cooled to 15°C with chilled water, and then enters the second-effect waste gas absorption tower T-102 (19 theoretical plates) for secondary washing, and the secondary washing water is alcohol-containing wastewater at 10°C 5t / h(H 2 O=70wt%, EG=30wt%, PG=0wt%), the content of EO in the gas phase after washing is respectively trace amou...

Embodiment 3

[0031] Such as figure 1 As shown in the process flow, the temperature of waste gas containing EO / PO is 120°C, and the flow rate is 969.646kg / h (N 2 =71.3wt%, EO=28.7wt%, PO=0wt%) are washed by one-effect exhaust gas absorption tower T-101 (theoretical plate number 19 pieces), and washing water is the alcoholic waste water 30t / h of 80 ℃ (H 2 O=70wt%, EG=30wt%, PG=wt%), the exhaust gas at the top of the tower enters the first-effect cooler E-101 after being absorbed, and is cooled to 45°C with circulating water, and the cooled material enters the liquid separation tank V-101 for separation , the tank top gas phase enters the second-effect cooler and is cooled to 15°C with chilled water, and then enters the second-effect waste gas absorption tower T-102 (19 theoretical plates) for secondary washing, and the secondary washing water is alcohol-containing wastewater at 10°C 5t / h(H 2 O=70wt%, EG=30wt%, PG=0wt%), the content of EO in the gas phase after washing is 682PPB, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com