A method for improving the recovery rate of colloidal tin ore body beneficiation

A technology of recovery rate and colloidal cassiterite, applied in chemical instruments and methods, flotation, solid separation, etc., can solve the problems of unsatisfactory effect, low recovery rate of ore dressing, low recovery rate of colloidal tin beneficiation, etc. The effect of low mineral processing recovery rate, improving economic benefits, and increasing the value of "three rates"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

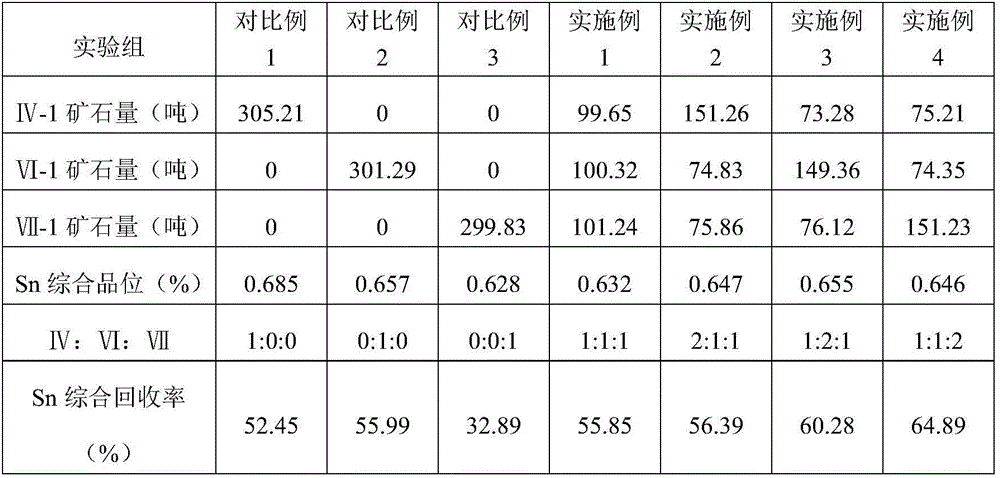

Embodiment 1

[0025] A method for improving the beneficiation recovery rate of colloidal tin ore body, the concrete steps are:

[0026] 1) After the cassiterite and colloidal cassiterite are ground and mixed according to a certain ratio, the cassiterite is divided into two parts, which are respectively selected into the IV-1 ore body and the VI-1 ore body of the Pengshan Tin Mine in Jiangxi, and the IV-1 ore The mass percentage of cassiterite Sn in the body is 0.6% to 0.8%, the mass percentage of cassiterite Sn in the Ⅵ-1 ore body is 0.6% to 0.75%, and the colloidal cassiterite is selected from the Ⅶ- 1 Ore body, wherein the mass percentage of Sn is 40% to 45%, SnO 2 The mass percentage is 55% to 60%. The mixing ratio is mixed uniformly according to the mass ratio IV-1:VI-1:VII-1=1:1:1. After mixing, the mixed powder is sieved, and then the sifted powder is soaked in a mixed acid of hydrochloric acid and hydrofluoric acid to remove impurities, and after the removal of impurities is comple...

Embodiment 2

[0032] A method for improving the beneficiation recovery rate of colloidal tin ore body, the concrete steps are:

[0033] 1) After the cassiterite and colloidal cassiterite are ground and mixed according to a certain ratio, the cassiterite is divided into two parts, which are respectively selected into the IV-1 ore body and the VI-1 ore body of the Pengshan Tin Mine in Jiangxi, and the IV-1 ore The mass percentage of cassiterite Sn in the body is 0.6% to 0.8%, the mass percentage of cassiterite Sn in the Ⅵ-1 ore body is 0.6% to 0.75%, and the colloidal cassiterite is selected from the Ⅶ- 1 Ore body, wherein the mass percentage of Sn is 40% to 45%, SnO 2 The mass percentage is 55% to 60%. The mixing ratio is mixed uniformly according to the mass ratio IV-1:VI-1:VII-1=2:1:1. After mixing, the mixed powder is sieved, and then the sifted powder is soaked in a mixed acid of hydrochloric acid and hydrofluoric acid to remove impurities, and after the removal of impurities is comple...

Embodiment 3

[0039] A method for improving the beneficiation recovery rate of colloidal tin ore body, the concrete steps are:

[0040] 1) After the cassiterite and colloidal cassiterite are ground and mixed according to a certain ratio, the cassiterite is divided into two parts, which are respectively selected into the IV-1 ore body and the VI-1 ore body of the Pengshan Tin Mine in Jiangxi, and the IV-1 ore The mass percentage of cassiterite Sn in the body is 0.6% to 0.8%, the mass percentage of cassiterite Sn in the Ⅵ-1 ore body is 0.6% to 0.75%, and the colloidal cassiterite is selected from the Ⅶ- 1 Ore body, wherein the mass percentage of Sn is 40% to 45%, SnO 2 The mass percentage is 55% to 60%. The mixing ratio is mixed uniformly according to the mass ratio IV-1:VI-1:VII-1=1:2:1. After mixing, the mixed powder is sieved, and then the sifted powder is soaked in a mixed acid of hydrochloric acid and hydrofluoric acid to remove impurities, and after the removal of impurities is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com