Multi-wire grinding device

A grinding and grinding technology, which is applied in grinding drive devices, grinding/polishing safety devices, grinding slides, etc., can solve the problems of restricting the application of non-metallic superhard materials, burning the surface of workpieces, and high processing temperature. Achieve the effect of reducing deformation, reducing thermal damage and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

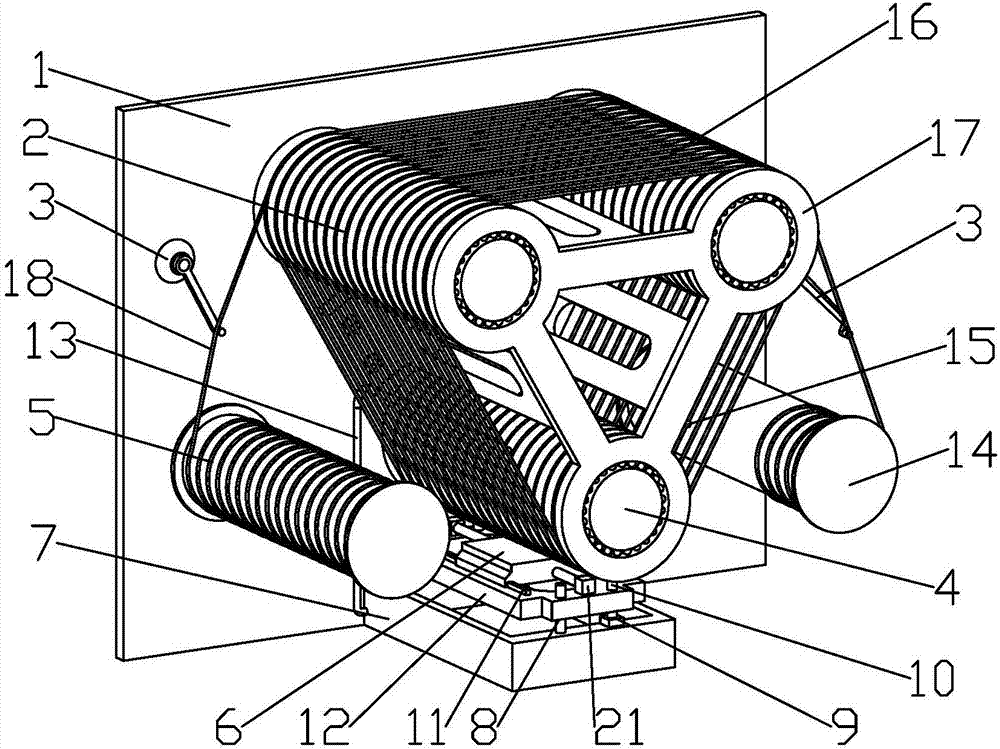

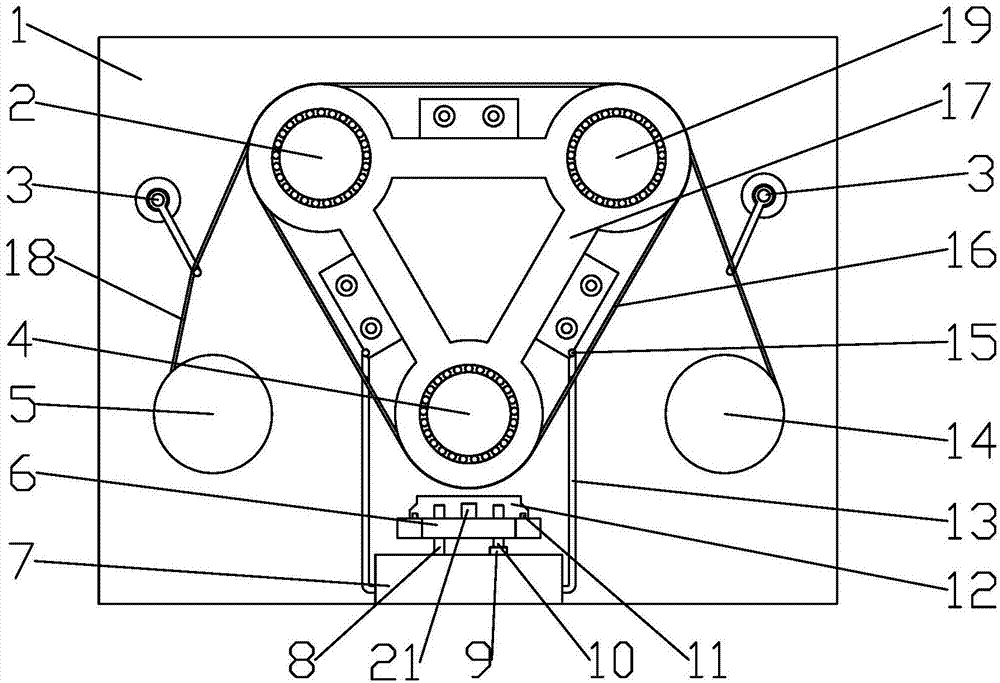

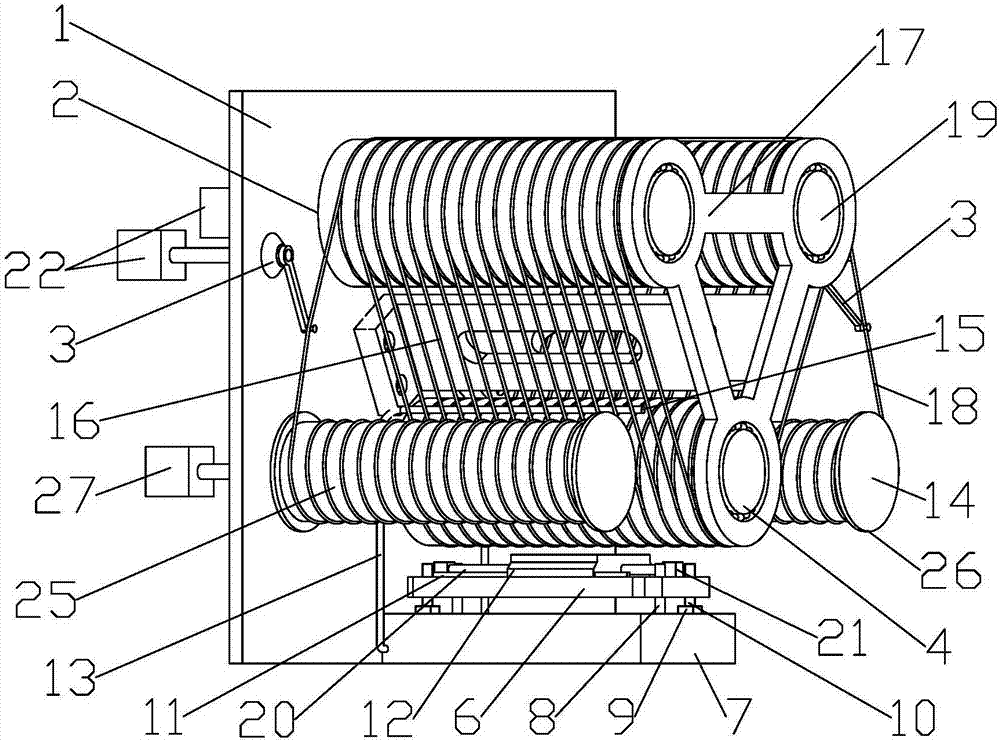

[0040] A multi-line grinding device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings

[0041]The multi-wire grinding processing device of the present invention is a processing device combining multi-wire cutting and grinding wheel grinding. The steel wire is used as the diamond wire base, and a layer of artificial diamond abrasive grains is uniformly consolidated on the surface of the steel wire. The diamond wire passes through the pay-off wheel, guide wheel, tensioning mechanism in turn, and the contact wheel, guide wheel, tensioning mechanism, and take-up wheel are arranged on the contact wheel to form a grinding tool, which is held by the V-shaped groove on the contact wheel The shape of the diamond wire row prevents the diamond wires from interfering with each other during the grinding process, and at the same time provides a certain normal grinding force to grind the workpiece. Nearly a hundred diamond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com