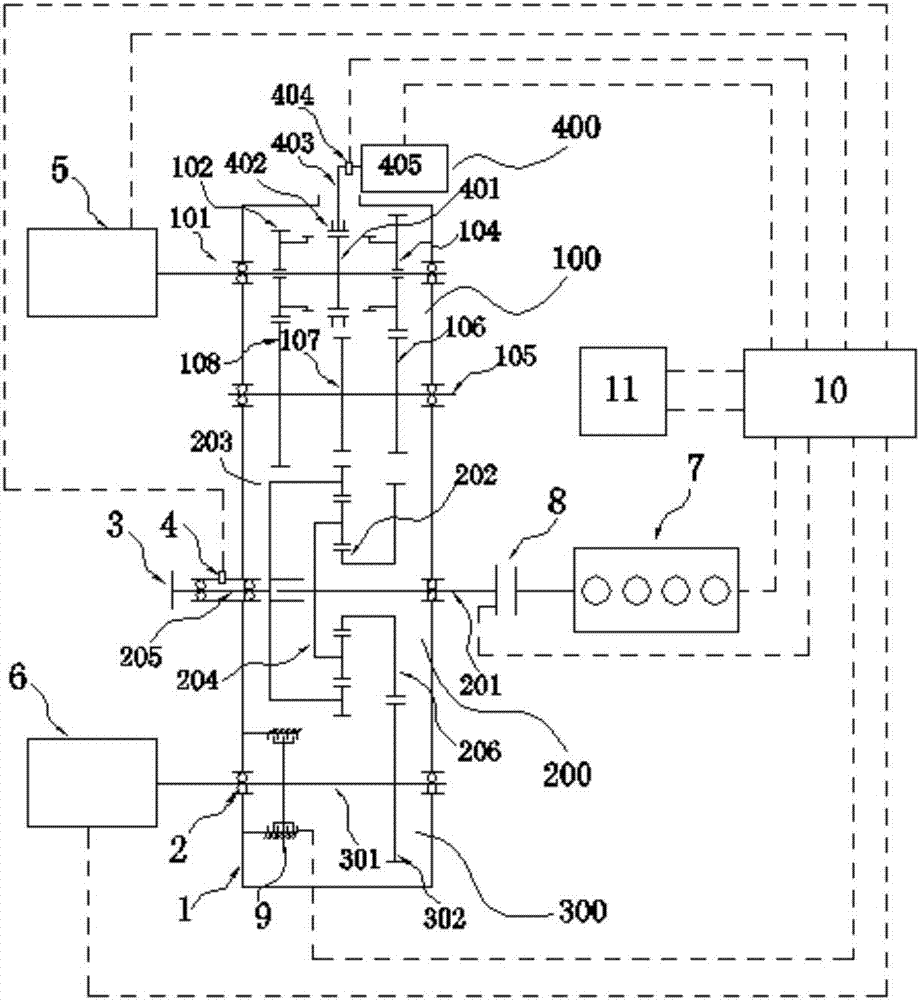

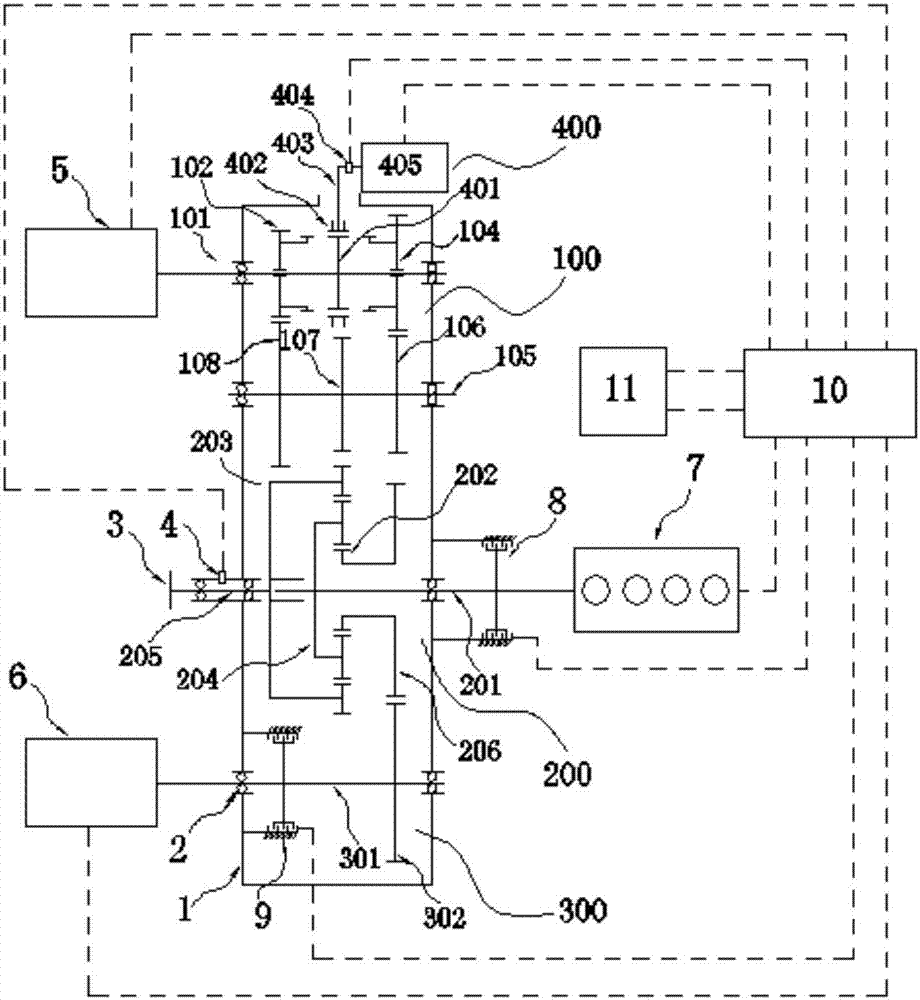

Multi-power two-speed coupled speed variator

A technology of speed change device and multi-power, which is applied in the arrangement of multiple different prime movers of power device, pneumatic power device, and general power device, etc. It can solve the problem of complicated switching operation, difficult to withstand large torque, and low system reliability. problems, to achieve the effect of compact system structure, improved output power, and high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the first embodiment, the brake A and the brake B both use hydraulic brakes, and the drive motor and the generator are both assembled motors that can both provide external power and generate electricity, that is, both the drive motor and the generator include a drive winding and a power generation winding. , and is connected with an energy storage element (the battery 11 in the first embodiment).

[0043] In the first embodiment, the axis lines of the input shaft 1, the input shaft 2, the input shaft 3 and the intermediate shaft are parallel to each other and not on the same straight line, and the input shaft 1, the input shaft 2, the input shaft 3 and the intermediate shaft are in the radial direction. Arranged in a row, thereby reducing the axial size of the transmission and making room for the arrangement of other assemblies.

[0044] In the first embodiment, the constant meshing gear is arranged at the position of the intermediate shaft corresponding to the engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com