Tail gas after-treatment pipeline system for internal combustion engineering machinery

A technology for exhaust after-treatment and pipeline system, applied in exhaust treatment, mechanical equipment, exhaust devices, etc., can solve the problems of substandard emission, heating failure of urea tank, wear and tear, etc., to ensure reliability, easy connection and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

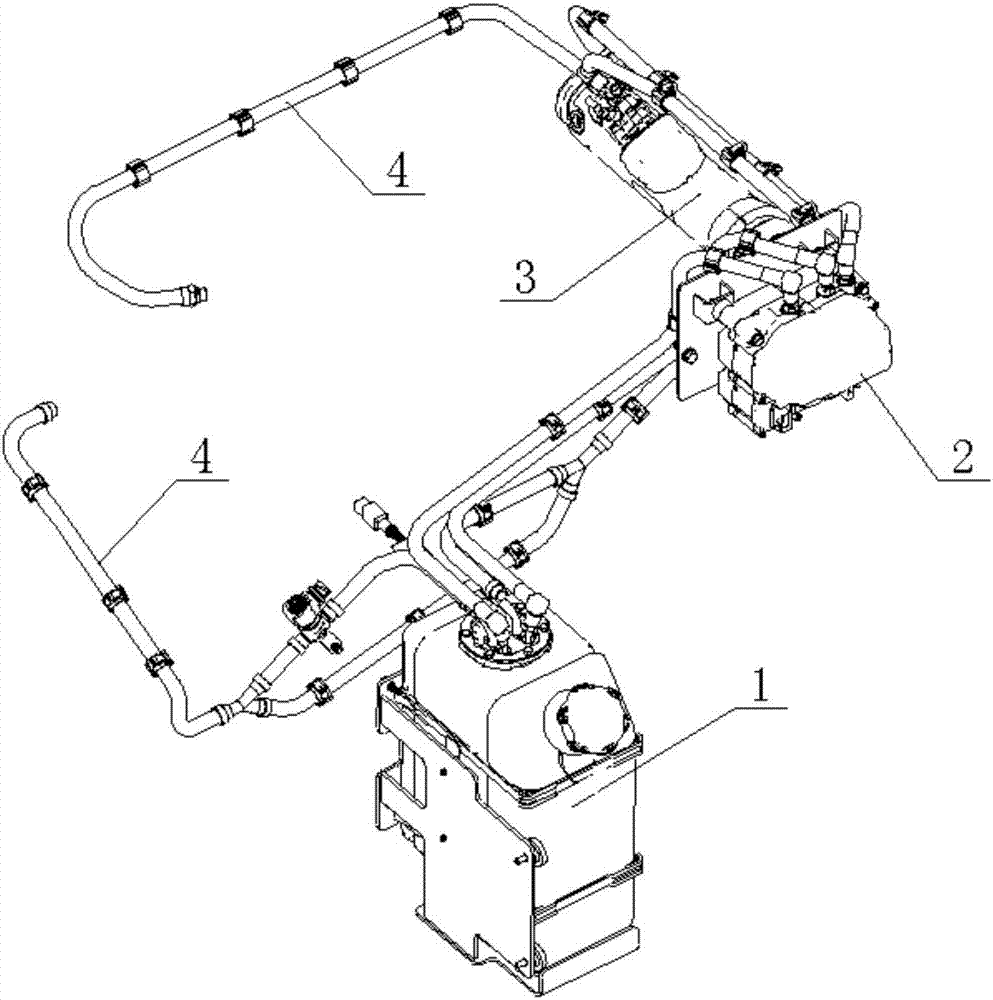

[0034] see figure 1 , an internal combustion engineering machinery exhaust gas post-treatment pipeline system, including a urea tank 1, a urea pump 2, a DRT pipe 3 and a cooling water pipeline 4.

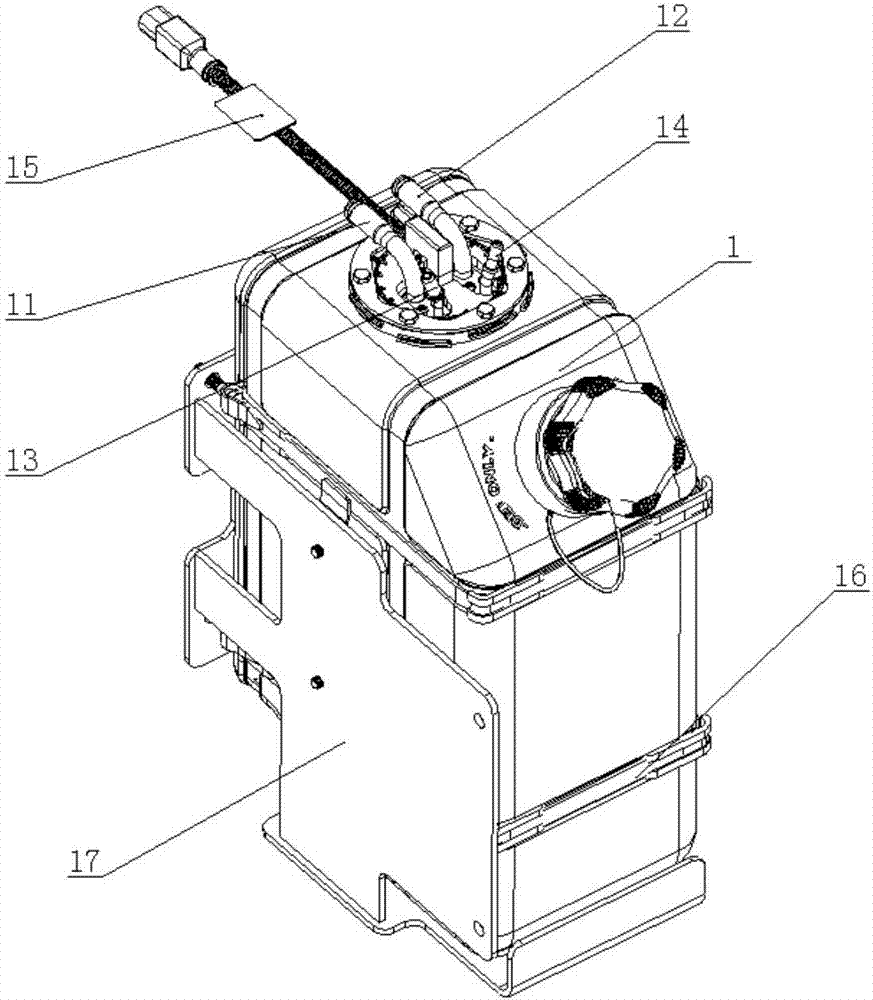

[0035] see figure 2 , the top of the urea tank 1 is provided with a pipeline integration cover, and the pipeline integration cover is provided with a water inlet interface 11, a water outlet interface 12, a urea suction interface 13, a urea return interface 14, and a temperature and urea level sensor 15. The water inlet port 11 , the water outlet port 12 are connected through the circulating cooling water path in the urea tank 1 . The urea suction interface 13 , the urea return interface 14 are connected through the inlet and outlet of the urea pump 2 . The temperature and urea liquid level sensor 15 senses the temperature signal of urea in the urea tank 1 and sends the temperature signal to the temperature control solenoid valve 49 . The urea tank 1 is provided with a hoop 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com