Multifunctional greenfeed beating device

A green fodder, multi-functional technology, applied in the field of agricultural machinery, can solve the problems of rough feed, loss of nutrients in green fodder, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

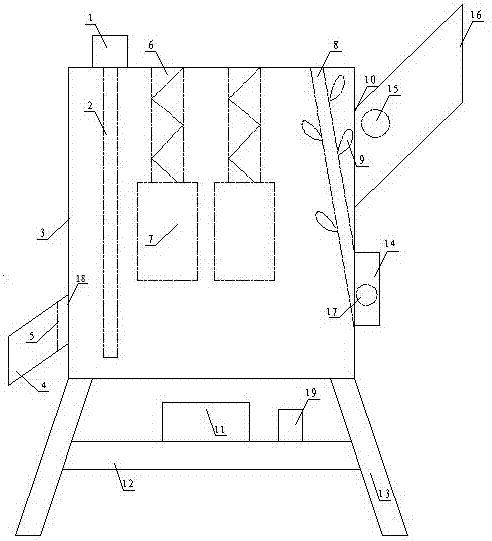

[0016] Such as figure 1 Described a kind of multifunctional green fodder beating device, comprises driver 1, scraper 2, body 3, discharge hopper 4, filter screen 5, elastic device 6, hammer blade 7, rotating shaft 8, blade 9, feed inlet 10, two Stage motor 11, cross bar 12, support 13, stage 1 motor 14, pressure sensor 15, feed plate 16, stage 1 signal sensor 17, discharge port 18, main controller 19, are set on body 3 side The feed port 10 and the feed plate 16 are connected to the body 3 through the feed port 10, a rotating shaft 8 is arranged in the body 3, several blades 9 are arranged on the rotating shaft 8, a primary motor 14 is arranged outside the body 3, and the primary motor 14 is connected to the Rotating shaft 8; Two or more elastic devices 6 are arranged at the inner upper end of the body 3, and the elastic device 6 is connected to the hammer 7. Supports 13 are arranged at the lower ends of both sides of the body 3, and cross bars 12 are arranged between the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com