Ceramic impeller gelcasting die and manufacturing method thereof

A technology of gel injection molding and manufacturing method, applied in the field of mold manufacturing, can solve the problems of reduced yield, poor appearance quality, and difficulty in demoulding an impeller blank, and achieves low cost, convenient demoulding, and good appearance quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

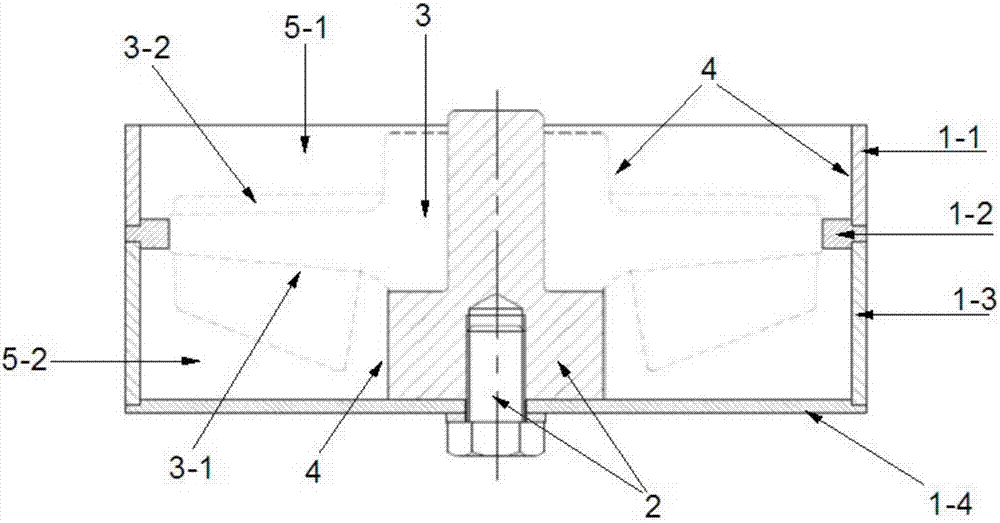

[0033] to combine figure 1 Example 1 is illustrated. The whole set of inventive device is composed of outer film 1, mold core stator 2, mold core 3 and anti-sticking coating 4, wherein outer film 1 includes upper die ring 1-1, middle ring 1-2, lower die ring 1-3 and bases 1-4. The mold core is the impeller mold core 3 to be poured. The impeller mold core 3 is installed in the outer mold cavity 5, and is fixed in the center of the outer membrane cavity 5 by the core stator. The outer membrane cavity 5 is divided into an upper mold cavity 5-1 and a lower mold cavity 5-2, wherein the upper mold cavity 5-1 is composed of an upper mold ring 1-1, an intermediate ring 1-2 and a core side 3- 2, the lower mold cavity 5-2 is composed of a base 1-4, a lower mold ring 1-3, an intermediate ring 1-2 and a mold core front 3-1 (including one side of the blade). The anti-sticking coating is applied on the surfaces of the impeller core 3, the core stator 2 and the outer membrane inner cavity...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the coating thickness of the anti-stick coating is 10 μm, and the thinnest part of the outer film is not less than 2 mm, and the pouring material is gypsum slurry. As a result of the implementation, a mold for gel injection molding of a ceramic impeller made of gypsum was obtained.

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is that the coating thickness of the anti-stick coating is 100 μm, and the thinnest part of the outer film is not less than 7 mm, and the pouring material is epoxy resin. As a result of the implementation, a mold for gel injection molding of a ceramic impeller made of epoxy resin was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com