Round step type magnetic bio-membrane reactor

A biofilm reactor and step-type technology, applied in the field of water treatment, can solve the problems of reduced reactor treatment efficiency, increased filler cost, and shortened operating cycle, achieving the effects of resource utilization, reduced loss, and improved operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

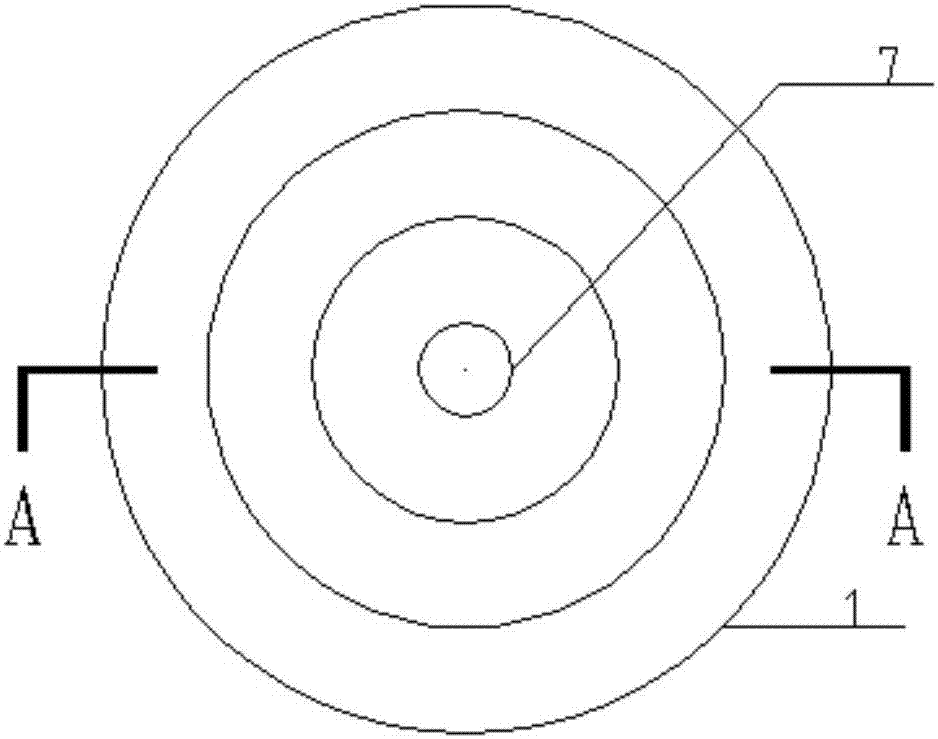

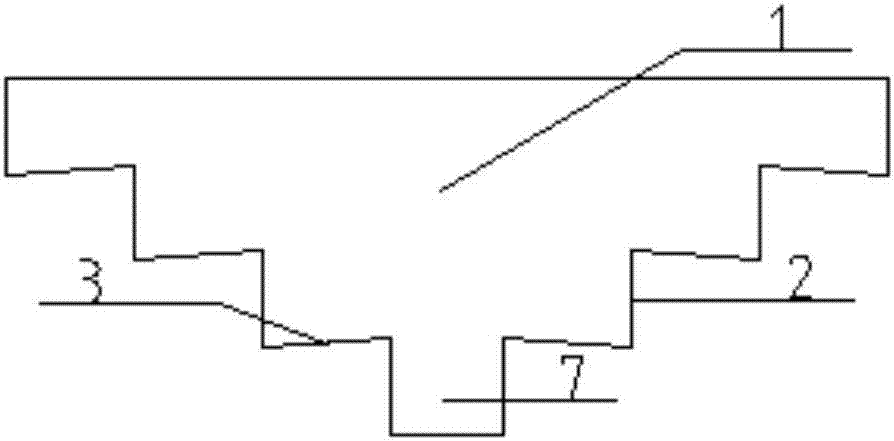

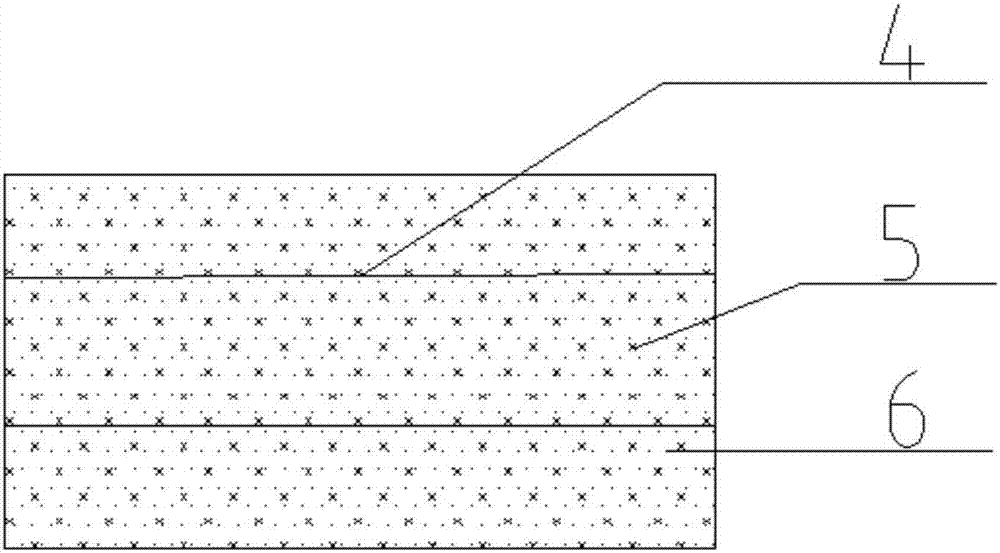

[0041] Such as figure 1 and figure 2 As shown, a circular stepped magnetic biofilm reactor includes a circular stepped shell 1, an outlet pipe 7 and a magnetic composite carrier. The circular stepped shell 1 is composed of several sets of hollow cylinders 2 and rings 3 of different sizes, and the diameter of the hollow cylinders 2 and the inner and outer diameters of the rings 3 decrease sequentially from top to bottom. Each group of hollow cylinder 2 and ring 3 is connected by welding the inner wall of the bottom end of the hollow cylinder 2 and the outer edge of the ring 3 .

[0042]In each group of hollow cylinder 2 and ring 3, the material of the hollow cylinder 2 is stainless steel, the wall thickness is 5mm, and the height is 500mm; the material of the ring 3 is stainless steel, the thickness is 5mm, and the outer diameter is the same as that of the hollow cylinder. 2 have the same inner diameter, the difference between the outer diameter of the ring 3 and the inner d...

Embodiment 2

[0055] A circular stepped magnetic biofilm reactor includes a circular stepped shell 1, an outlet pipe 7 and a magnetic composite carrier. The circular stepped shell 1 is composed of several sets of hollow cylinders 2 and rings 3 of different sizes, and the diameter of the hollow cylinders 2 and the inner and outer diameters of the rings 3 decrease sequentially from top to bottom. Each group of hollow cylinder 2 and ring 3 is connected together by glueing the inner wall of the bottom end of the hollow cylinder 2 and the outer edge of the ring 3 .

[0056] In each group of hollow cylinder 2 and ring 3, the material of the hollow cylinder 2 is plexiglass, the wall thickness is 10mm, and the height is 800mm; the material of the ring 3 is plexiglass, the thickness is 10mm, and the outer diameter is the same as The inner diameters of the hollow cylinders 2 are the same, and the difference between the outer diameter of the ring 3 and the inner diameter of the ring 3 is 1600mm. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com