Compound type anti-gas-channeling agent for carbon-dioxide flooding

A carbon dioxide and anti-gas channeling agent technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as reducing the contact efficiency of carbon dioxide and crude oil, increasing the water saturation of oil layers, and affecting foaming and foam stabilizing performance , to achieve the effect of broad market application prospects, strong fluidity and strong migration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This example provides a composite anti-gas channeling agent for carbon dioxide flooding, and its raw material composition is shown in Table 3.

[0060] table 3

[0061]

[0062] The gel strength of the composite anti-gas channeling agent for carbon dioxide flooding in this example was evaluated, and the results are shown in Table 4.

[0063] Table 4

[0064] time / d 1 7 30 60 90 120 180 strength H H H H H H H

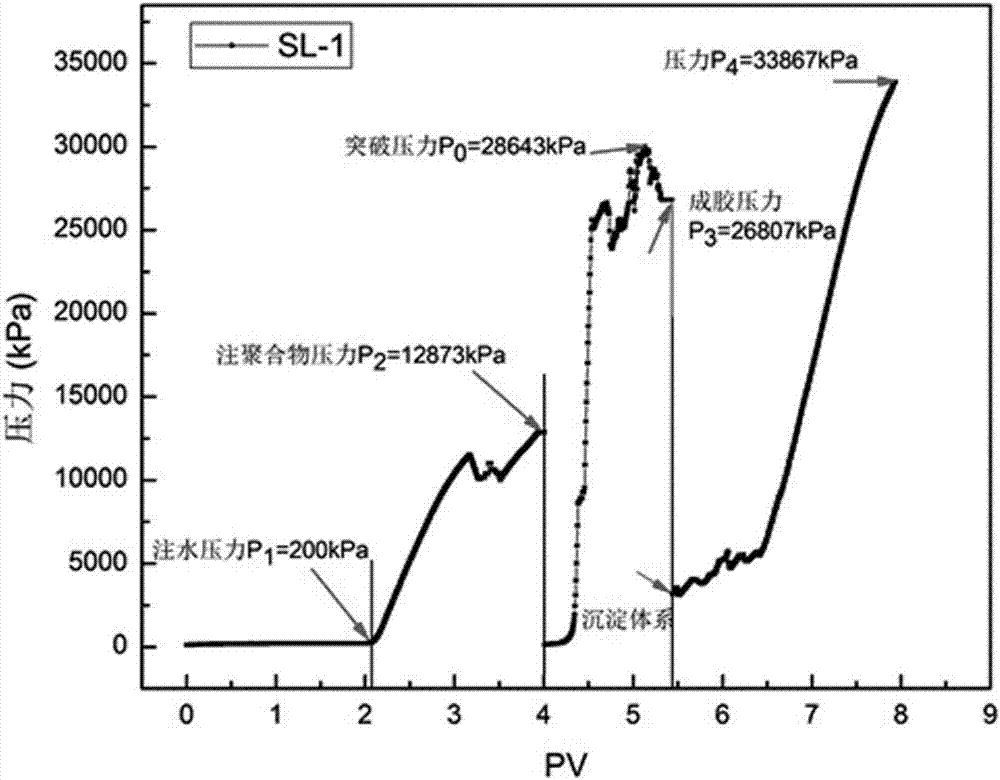

[0065] The composite anti-gas channeling agent for carbon dioxide flooding in this example was tested for anti-gas channeling performance, and the injection pressure and the curve were as follows: figure 1 shown. The core plugging rate measurement table is shown in Table 5.

[0066] table 5

[0067] Pore volume / cm 3

Embodiment 2

[0069] This example provides a composite anti-gas channeling agent for carbon dioxide flooding, and its raw material composition is shown in Table 6.

[0070] Table 6

[0071]

[0072] The gel strength of the composite anti-gas channeling agent for carbon dioxide flooding in this example was evaluated, and the results are shown in Table 7.

[0073] Table 7

[0074] time / d 1 7 30 60 90 120 180 strength F G H H H H H

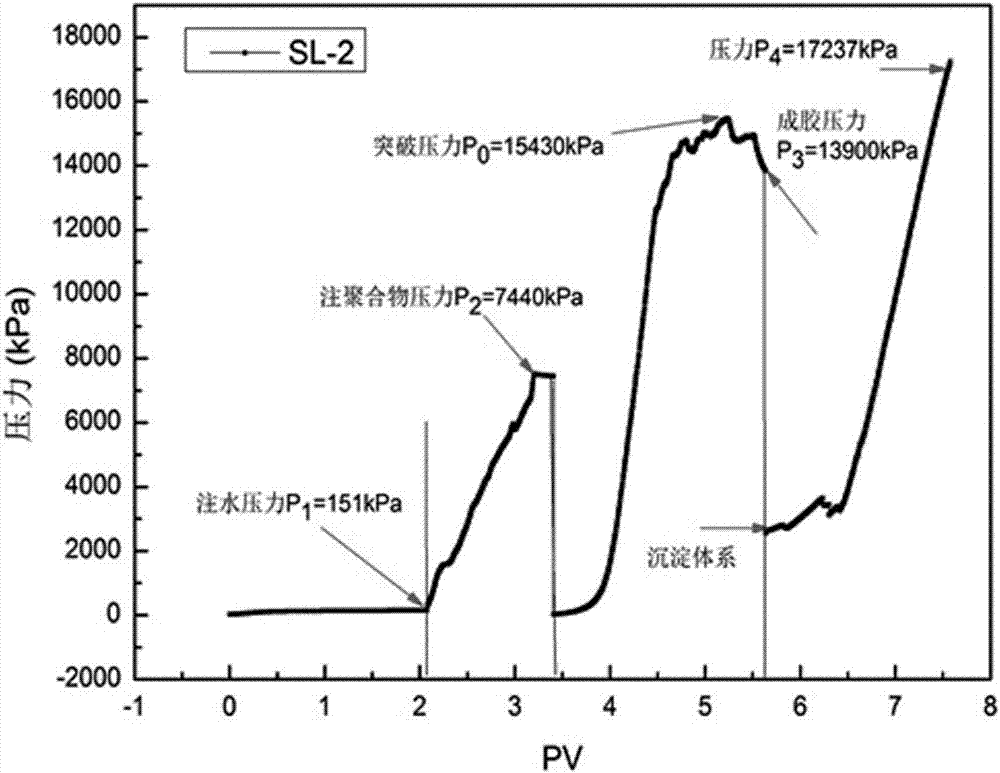

[0075] The composite anti-gas channeling agent for carbon dioxide flooding in this example was tested for anti-gas channeling performance, and the injection pressure and the curve were as follows: figure 2 shown. Table 8 shows the core plugging rate measurement table.

[0076] Table 8

[0077] Pore volume / cm 3

Embodiment 3

[0079] This example provides a composite anti-gas channeling agent for carbon dioxide flooding, and its raw material composition is shown in Table 9.

[0080] Table 9

[0081]

[0082] The gel strength of the composite anti-gas channeling agent for carbon dioxide flooding in this example was evaluated, and the results are shown in Table 10.

[0083] Table 10

[0084] time / d 1 7 30 60 90 120 180 strength G H H H H H H

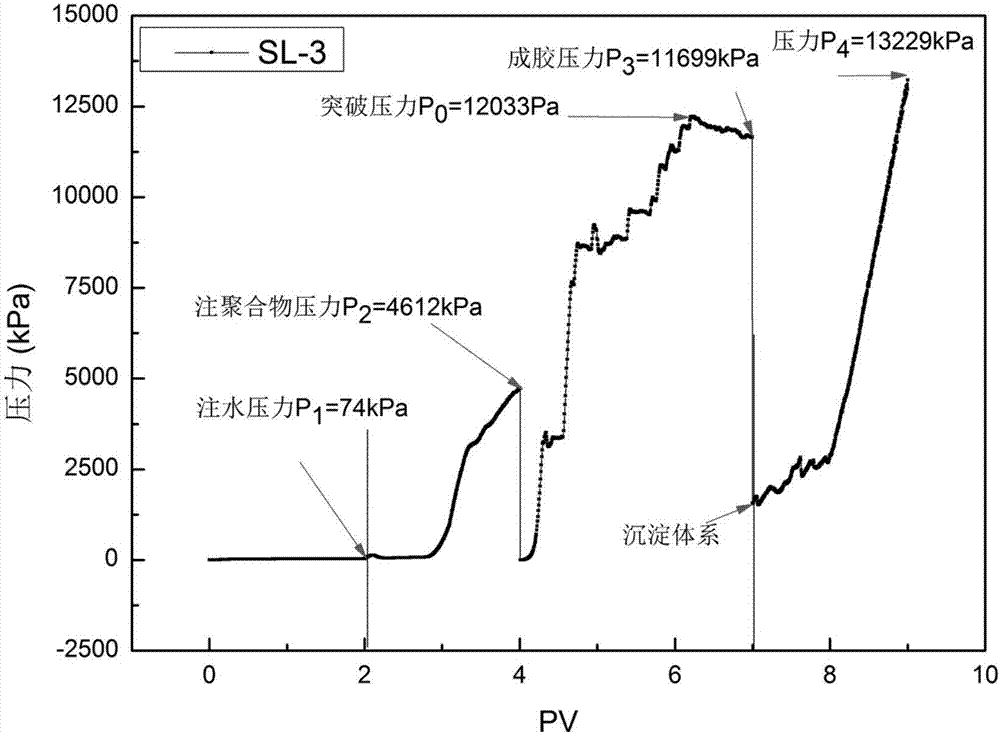

[0085] The composite anti-gas channeling agent for carbon dioxide flooding in this example was tested for anti-gas channeling performance, and the injection pressure and the curve were as follows: image 3 shown. Table 11 shows the measurement table of core plugging rate.

[0086] Table 11

[0087] Pore volume / cm 3

[0088] The above examples illustrate that the composite anti-gas channeling agent for carbon dioxide flooding of the present invention has good gas channeling prevention effect, high plugging ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com