A kind of preparation method of anti-rust and anti-corrosion iron-nickel alloy strip

An iron-nickel alloy and strip technology is applied in the field of preparation of rust-resistant and corrosion-resistant iron-nickel alloy strips, and can solve the problems of poor surface quality of ingots, poor homogeneity of hot-rolled billets, and poor surface quality, etc. Achieve the effect of saving manpower, improving product yield and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

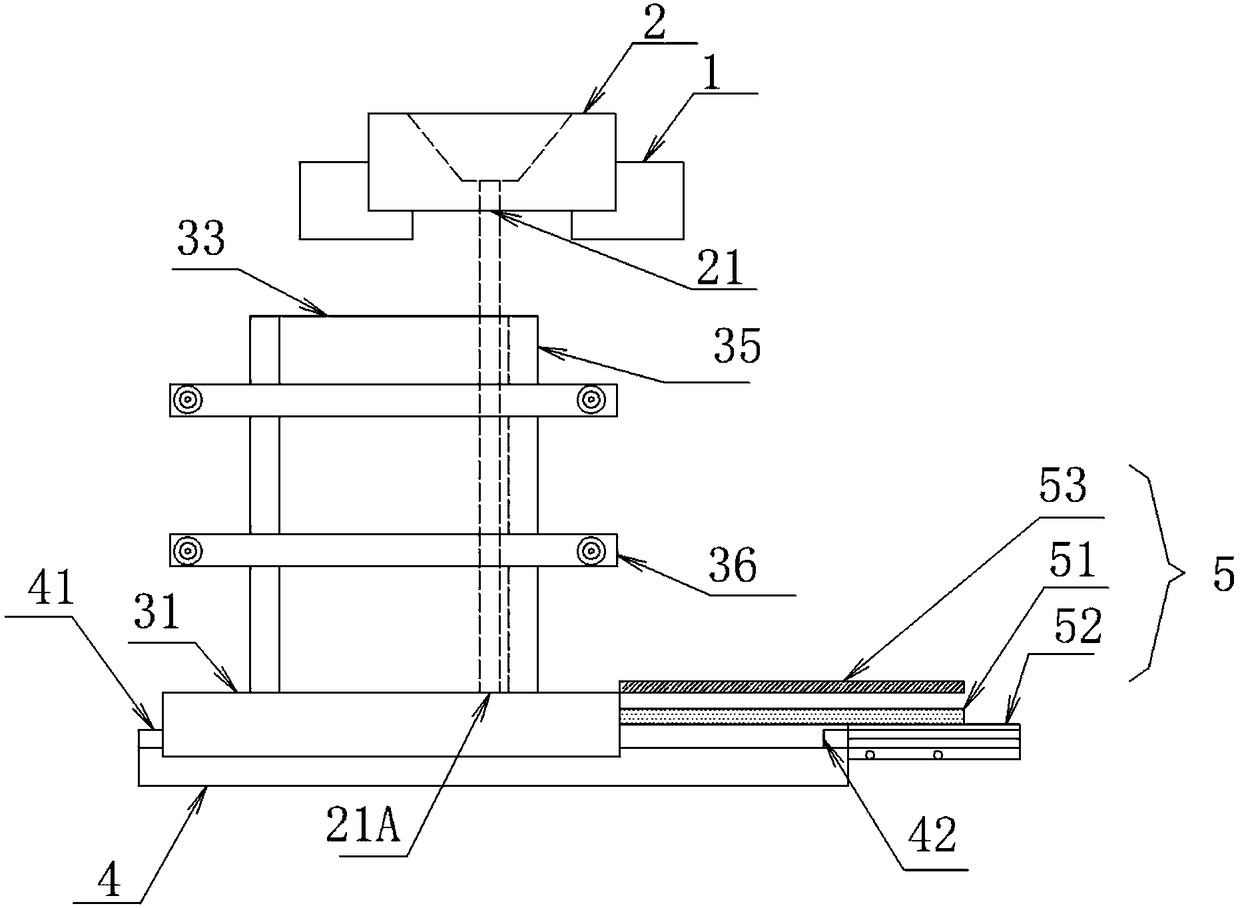

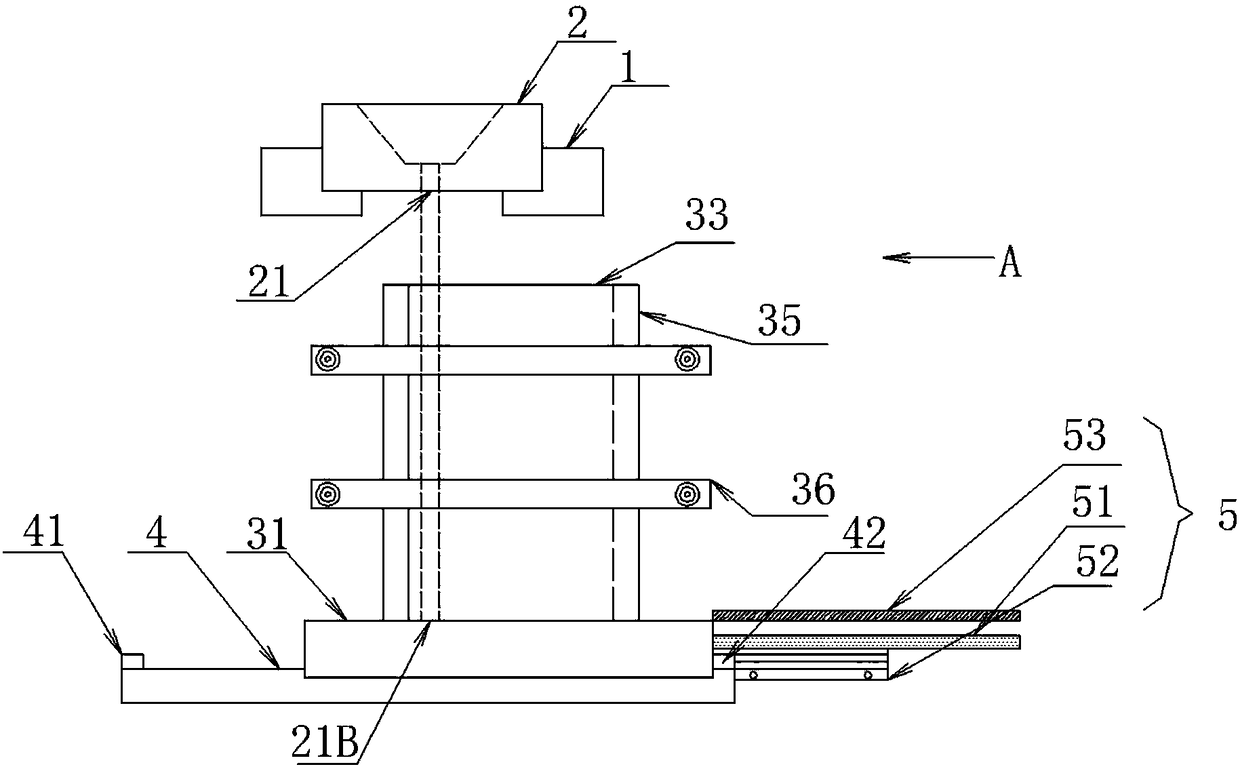

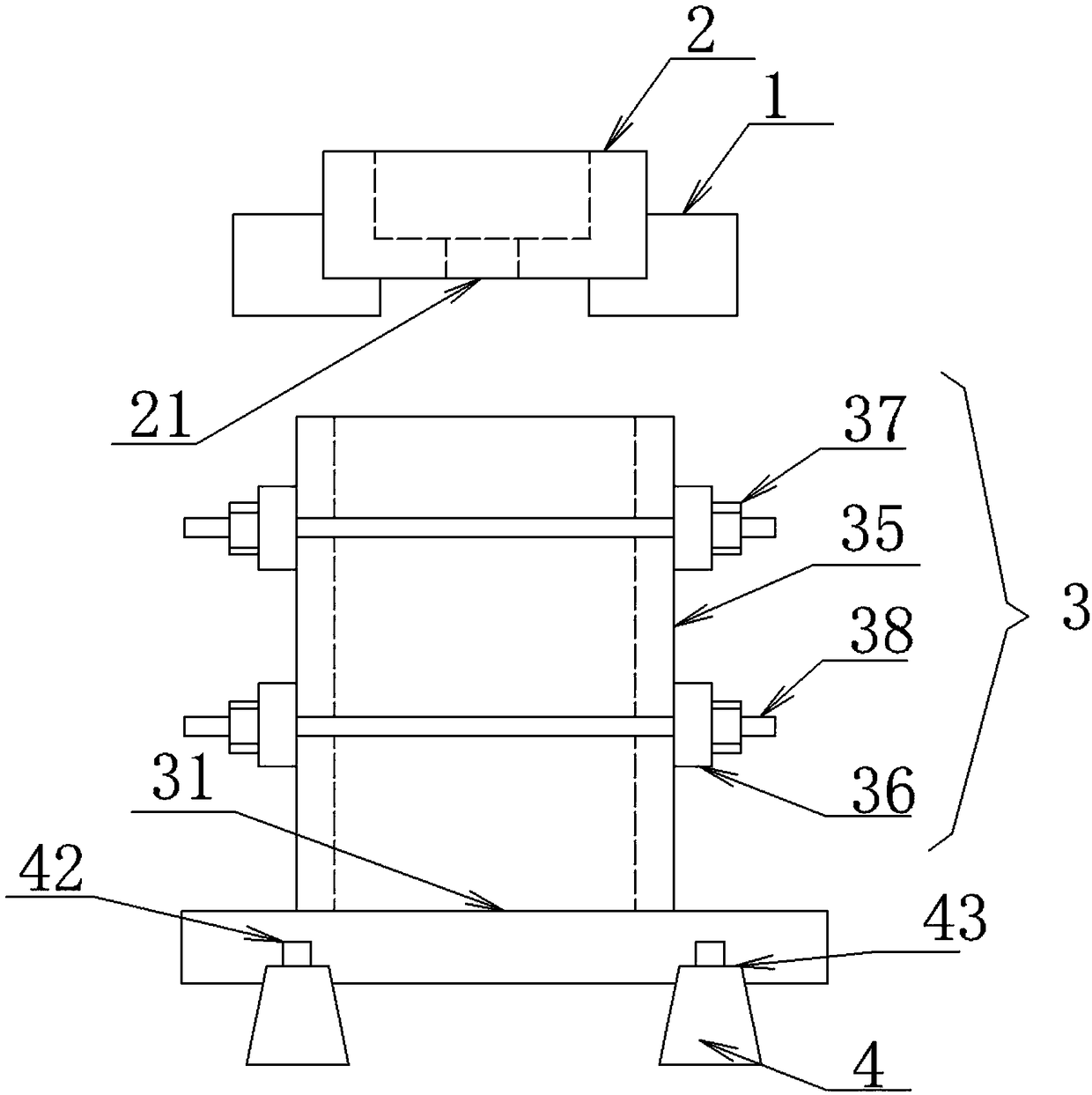

Image

Examples

Embodiment 1

[0031] A kind of preparation method of rust-proof and corrosion-resistant iron-nickel alloy strip provided by the present embodiment is implemented according to the following steps:

[0032] S1: Put the raw materials into the vacuum induction smelting furnace according to the proportion of ingredients, heat up to 1510°C under vacuum conditions, melt and refine them into alloy melt; the mass percentages of the raw materials are respectively 16.0% nickel, 8.0% chromium, and 0.6% zirconium. %, manganese 0.3%, silicon 0.15%, carbon 0.01%, iron 74.94%.

[0033] S2: The alloy melt is evenly poured into the flat combined ingot mold, and the pouring temperature is controlled at 1530°C. During the pouring process, the alloy melt is evenly poured into the flat combined ingot mold by reciprocating movement. An alloy slab with a width of 300 mm and a thickness of 70 mm is formed in the flat combined ingot mold, and the alloy slab is partially finished after it is demoulded and cooled.

...

Embodiment 2

[0044] A kind of preparation method of rust-proof and corrosion-resistant iron-nickel alloy strip provided by the present embodiment is implemented according to the following steps:

[0045] S1: Put the raw materials into the vacuum induction smelting furnace according to the proportion of ingredients, heat up to 1530°C under vacuum conditions, melt and refine them into alloy melt; the mass percentages of the raw materials are respectively 18.0% nickel, 9.0% chromium, and 1% zirconium. %, manganese 0.8%, silicon 0.3%, carbon 0.03%, iron 70.87%. ;

[0046] S2: The alloy melt is evenly poured into the flat combined ingot mold, and the pouring temperature is controlled at 1540°C. During the pouring process, the alloy melt is evenly poured into the flat combined ingot mold by reciprocating movement. An alloy slab with a width of 500 mm and a thickness of 50 mm is formed in the slab composite ingot mold, and the alloy slab is partially finished after it is demoulded and cooled.

...

Embodiment 3

[0055] A kind of preparation method of rust-proof and corrosion-resistant iron-nickel alloy strip provided by the present embodiment is implemented according to the following steps:

[0056] S1: Put the raw materials into the vacuum induction smelting furnace according to the proportion of ingredients, heat up to 1580°C under vacuum conditions, melt and refine them into alloy melt; the mass percentages of the raw materials are respectively 17.0% nickel, 8.5% chromium, and 0.8% zirconium. %, manganese 0.5%, silicon 0.2%, carbon 0.02%, iron 72.98%.

[0057] S2: The alloy melt is evenly poured into the flat combined ingot mold, and the pouring temperature is controlled at 1560°C. During the pouring process, the alloy melt is evenly poured into the flat combined ingot mold by reciprocating movement. An alloy slab with a width of 400 mm and a thickness of 40 mm is formed in the flat composite ingot mold, and the alloy slab is partially finished after it is demoulded and cooled.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com