Preparation method of synthetic steam turbine oil

A technology of steam turbine oil and base oil, which is applied in the petroleum industry, lubricating compositions, base materials, etc. It can solve the problems of mineral oil such as short service life, frequent oil changes and failures, and influence on production efficiency, so as to achieve carbon deposition tendency Low, improved viscosity-temperature performance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

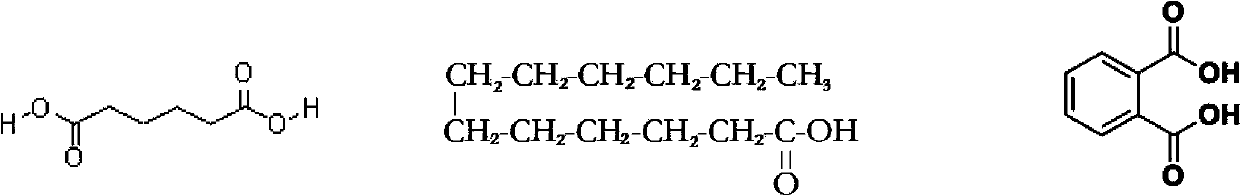

Method used

Image

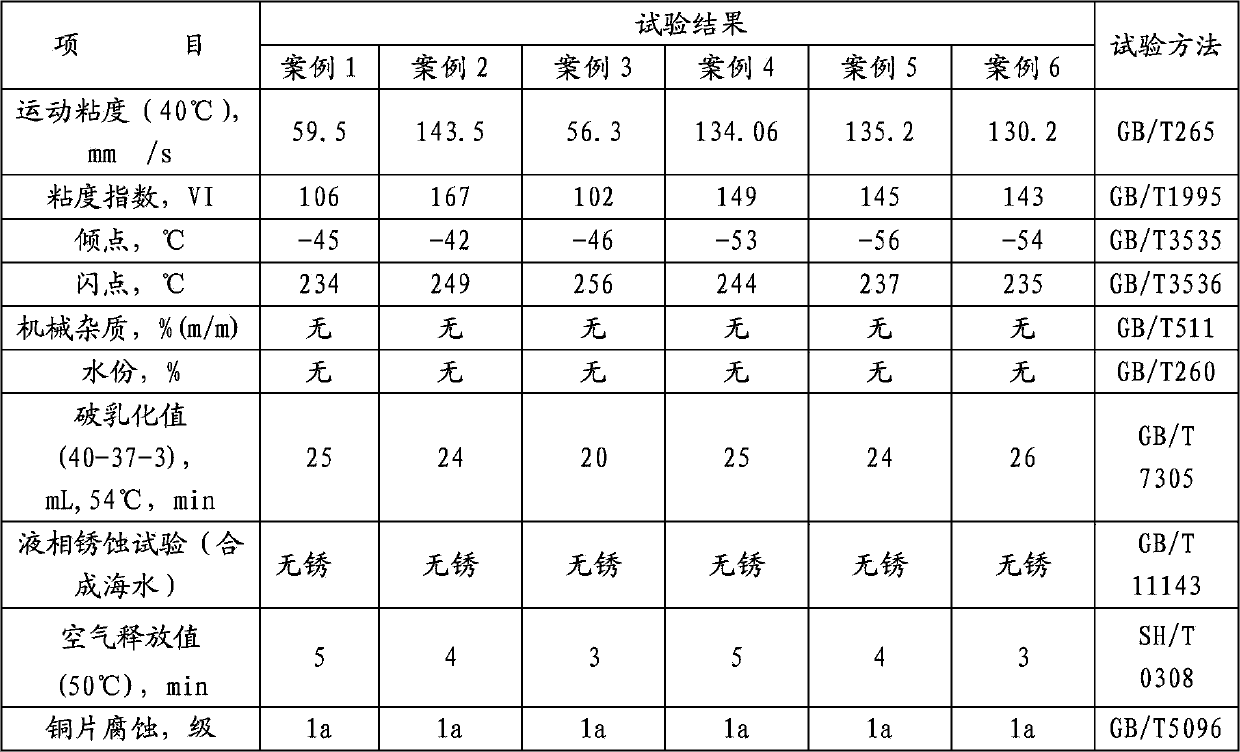

Examples

Embodiment 1

[0029] Add 52.6 parts of mixed ester A and 42.41 parts of mineral oil into a stainless steel mixing tank with agitator for reaction, keep the temperature of the tank at 60°C, and stir continuously for 2 hours; Part of phenyl phosphorothioate, 1 part of isopropanolamine, 0.5 part of zinc naphthenate, 0.4 part of barium polyisobutylene sulfur phosphate, 0.3 part of YM high-efficiency metal deactivator, 0.01 part of polyoxypropylene glycerol ether, Put 0.08 parts of polyethylene oxide-propylene oxide ether into the blending kettle, keep the temperature of the kettle at 75°C, and stir continuously for 2 hours until the mixture is completely dissolved and becomes uniform, and the finished steam turbine oil is obtained.

Embodiment 2

[0031] Add 57.3 parts of mixed ester B, 8 parts of polyisobutylene and 28.49 parts of mineral oil into a stainless steel mixing kettle with agitator for reaction, keep the temperature of the kettle at 55°C, and continue stirring for 2 hours; sequentially add 1 part of benzotriazole fatty acid amine Salt, 1.5 parts of phenyl phosphorothioate, 1.3 parts of isopropanolamine, 1.5 parts of zinc naphthenate, 0.5 parts of sulfur phosphating polyisobutylene barium salt, 0.29 parts of YM high-efficiency metal deactivator, 0.02 parts of polyoxypropylene glycerine Add alcohol ether and 0.1 part of polyethylene oxide-propylene oxide ether into the blending kettle, keep the temperature of the kettle at 79°C, and continue stirring for 2 hours until the mixture is completely dissolved and becomes uniform, and the finished steam turbine oil is obtained.

Embodiment 3

[0033] Add 54.3 parts of mixed ester C and 41.9 parts of mineral oil into a stainless steel mixing kettle with agitator for reaction, keep the temperature of the kettle at 50°C, and continue stirring for 2 hours; sequentially add 1 part of benzotriazole fatty acid amine salt, 1 part of thio Phenyl phosphate, 0.5 part of isopropanolamine, 0.5 part of zinc naphthenate, 0.3 part of barium polyisobutylene sulfur phosphate, 0.35 part of YM high-efficiency metal deactivator, 0.01 part of polyoxypropylene glycerol ether, 0.14 part of poly Add ethylene oxide-propylene oxide ether into the blending kettle, keep the temperature of the kettle at 80°C, and continue stirring for 2 hours until the mixture is completely dissolved and becomes uniform, and the finished steam turbine oil is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com