An optical fiber sensor probe

An optical fiber sensing probe and optical fiber technology, applied in the field of sensing probes, can solve the problems of small frequency range, low signal-to-noise ratio, easy to be affected by changes in light source intensity and environmental temperature changes, etc. lower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

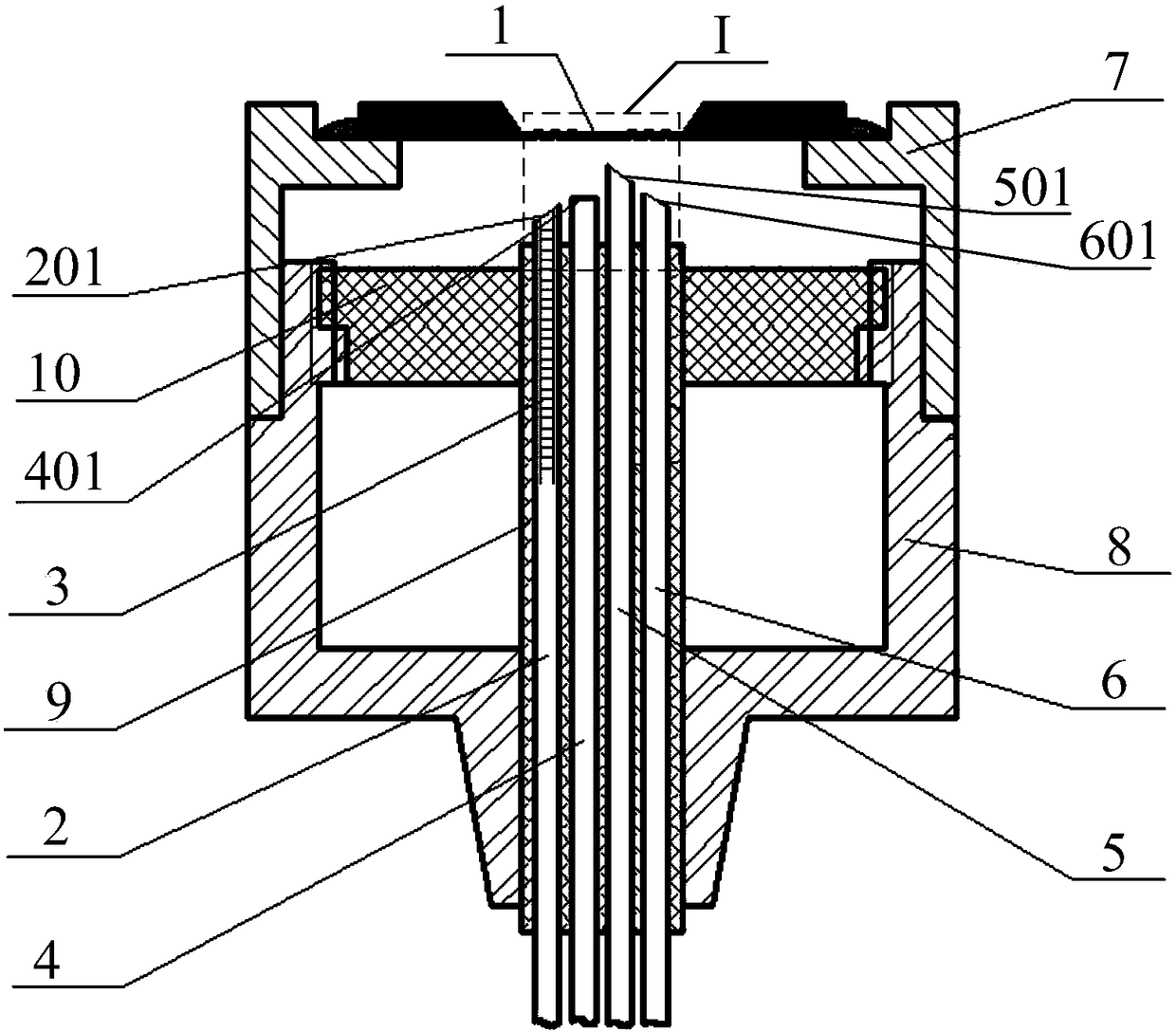

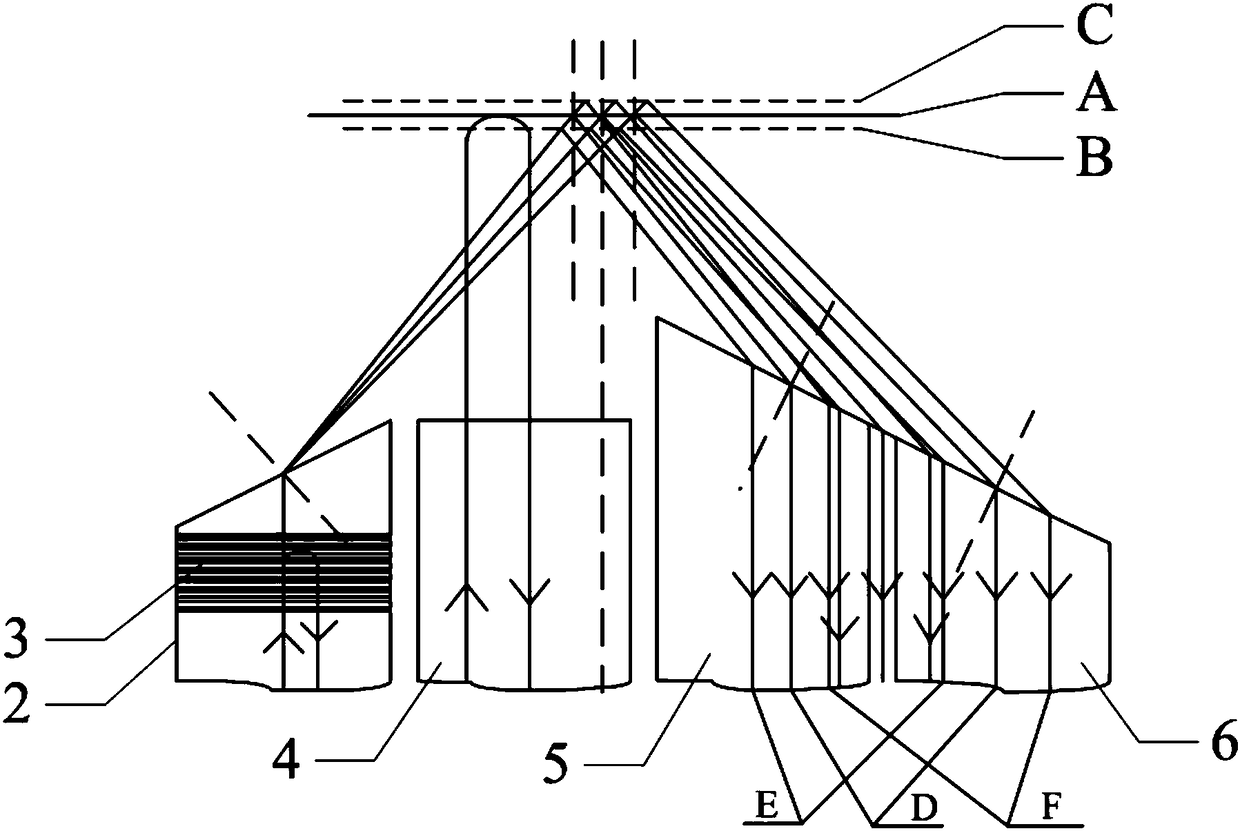

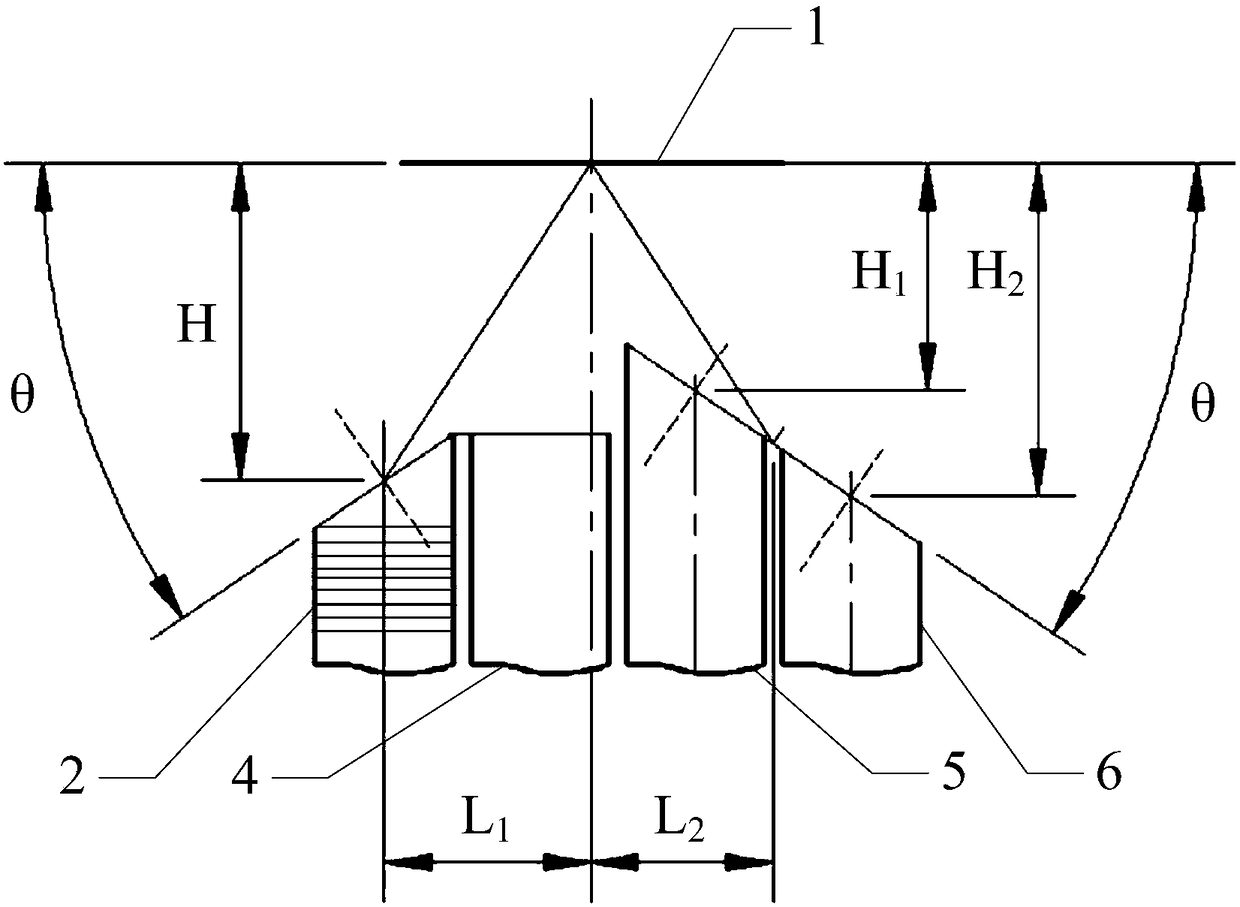

[0034] Embodiment one: combine below figure 1 and figure 2 This embodiment will be described in detail. An optical fiber sensing probe described in this embodiment includes a housing, a pressure sensitive diaphragm 1, a first emitting optical fiber, a second emitting optical fiber, a first receiving optical fiber and a second receiving optical fiber;

[0035] Both ends of the housing are open, and the pressure sensitive diaphragm 1 is arranged on one open end of the housing;

[0036] One end of the first emitting fiber is the first emitting end 2, and the fiber core of the first emitting end is engraved with a fiber grating 3, and the other end of the first emitting fiber is simultaneously connected with the first light source through the first fiber coupler. connected to the first spectrometer;

[0037] One end of the second launch fiber is the second launch end 4, and the other end of the second launch fiber is simultaneously connected to the second light source and the ...

Embodiment 2

[0053] Embodiment two: combine below figure 1 This embodiment will be described in detail. This embodiment is to further limit the optical fiber sensing probe described in the first embodiment.

[0054] An optical fiber sensing probe described in this embodiment, the housing includes an upper housing 7 and a lower housing 8, one open end and the other open end of the housing are respectively located on the upper housing 7 and the lower housing On the body 8, the upper shell 7 is screwed to the lower shell 8.

[0055] In this embodiment, the housing is a split structure, and the upper housing is screwed to the lower housing. The split housing facilitates the assembly of the optical fiber sensing probe and subsequent maintenance and repair.

Embodiment 3

[0056] Embodiment 3: This embodiment further limits the optical fiber sensing probe described in Embodiment 1.

[0057] An optical fiber sensing probe described in this embodiment is provided with a high reflective film on the reflective surface of the pressure sensitive diaphragm 1, the material of the high reflective film is gold, silver, palladium or titanium, and the high reflective film is made of gold, silver, palladium or titanium. The thickness of the reflection film is 10nm to 1000nm.

[0058] In this embodiment, a layer of high reflection film is provided on the reflective surface of the pressure sensitive diaphragm to increase the reflective ability of the pressure sensitive diaphragm.

[0059] In this embodiment, the material of the pressure-sensitive diaphragm is sapphire, silicon or silicon nitride, and the pressure-sensitive diaphragm made of these materials is highly sensitive to external pressure. The pressure-sensitive diaphragm made of sapphire is made by M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com