Hot Stamped Trim Parts

A hot stamping and trimming technology, applied in vehicle parts, manufacturing tools, transportation and packaging, etc., can solve the problems of higher processing costs, impaired productivity, longer processing time, etc., to achieve increased productivity, stable shape, restraint unstable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the following examples, the drawings are appropriately simplified or deformed for the sake of explanation, and the dimensional ratios, shapes, and the like of each part are not necessarily drawn accurately.

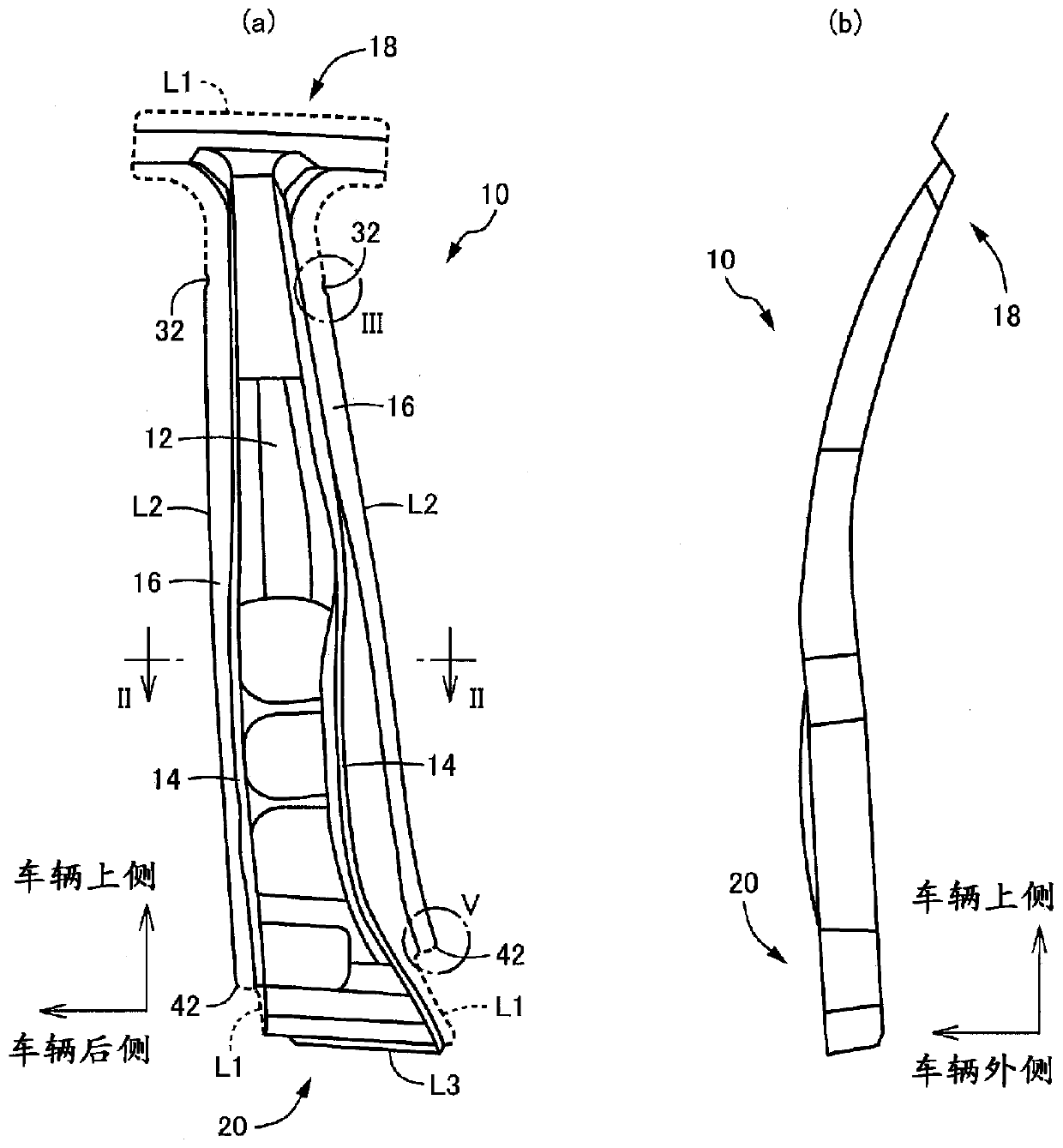

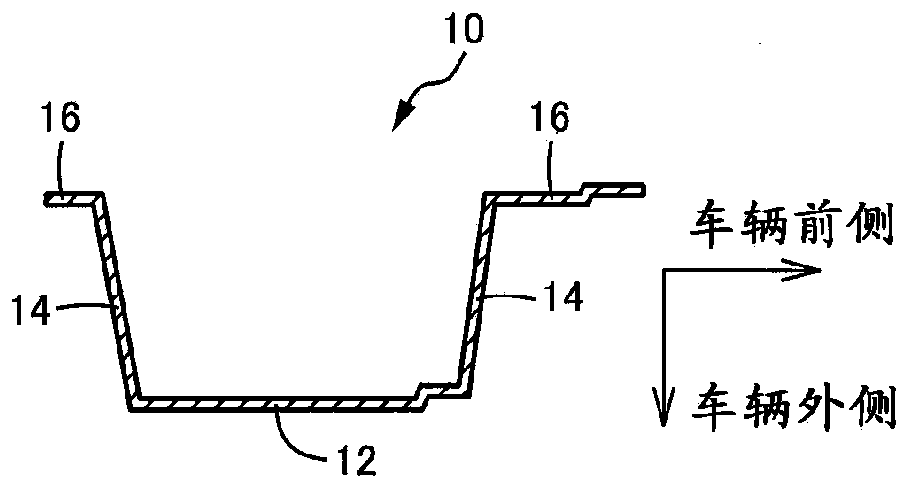

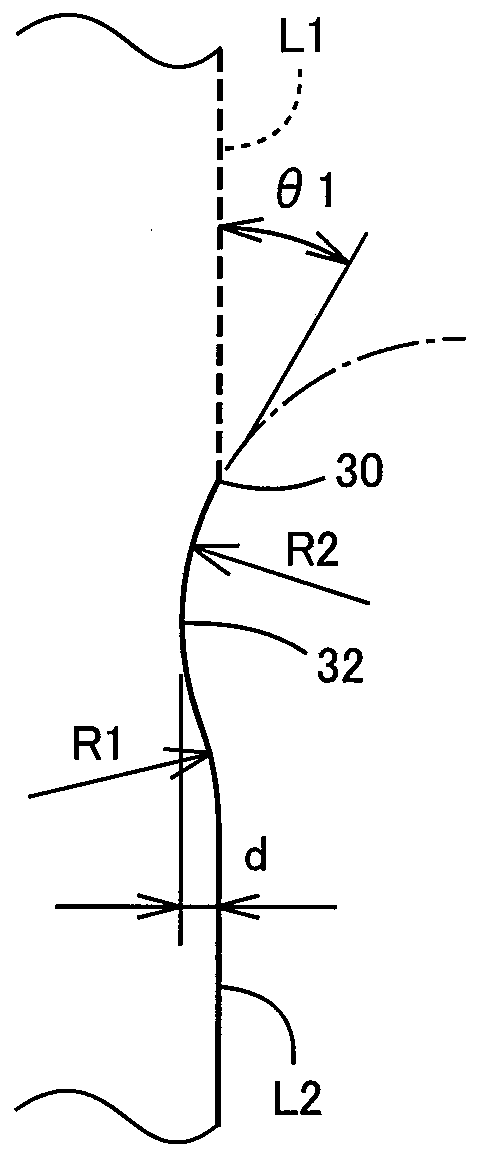

[0038] figure 1 It is two views which show the center pillar reinforcement 10 for vehicles which is one Example of this invention, (a) is a front view seen from the vehicle outer side, (b) is a right side view. in addition, figure 2 yes figure 1 The enlarged cross-sectional view of the II-II arrow in (a), image 3 yes figure 1 Enlarged view of part III in (a), Figure 4 yes figure 1 An enlarged view of another example of Part III in (a), Figure 5 yes figure 1 An enlarged view of the V portion in (a). The center pillar reinforcement 10 is disposed on the right side of the vehicle, has a long vertical shape in the vertical direction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com