Optical gas concentration measuring method, and method for monitoring gas concentration by said method

A technology of gas concentration and measurement method, applied in color/spectral characteristic measurement, material analysis by optical means, measurement device, etc., can solve the problem of whether the measured mixing ratio is the same as the actual mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

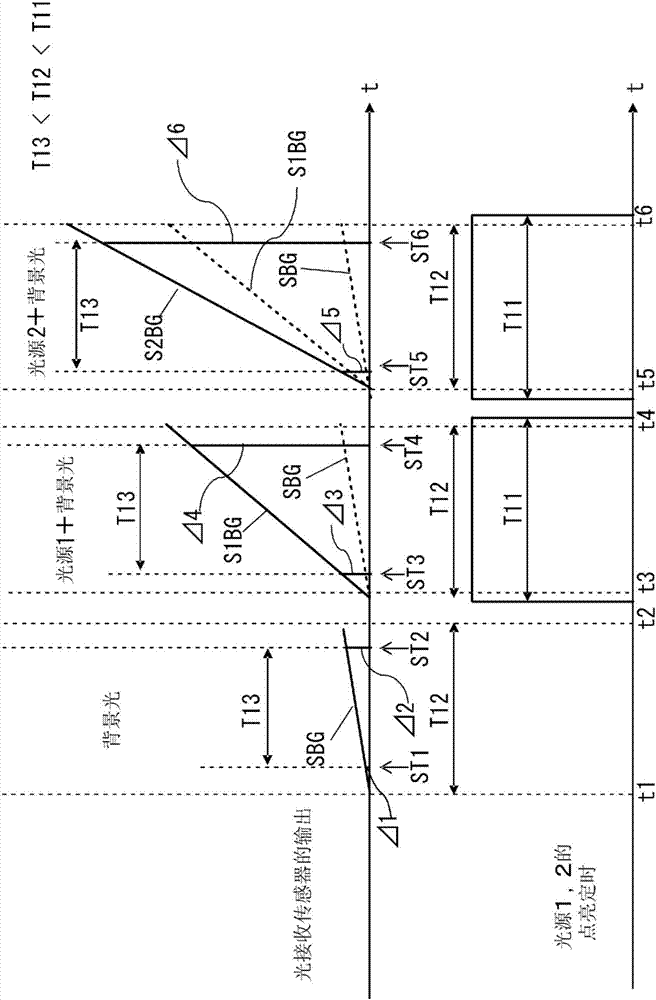

[0057] figure 1 It is a timing chart for explaining the principle of the optical gas concentration measuring method according to the present invention.

[0058] exist Figure 18 In this case, light sources 1 and 2 are turned on (ON) / off (OFF) regularly with a pulse width T11 (lighting time) as shown in the figure (the pulse width T11 is the light source light source that makes light sources 1 and 2 light up). pulse width of pulse PL).

[0059] As shown in the figure, the light-receiving sensor is regularly lit with pulse width T12 (the time when the light-receiving sensor receives light and outputs an output signal corresponding to the light-receiving amount) (the pulse width T12 is the time when the light-receiving sensor is turned on / off). pulse width of sensor drive pulse SP for OFF drive).

[0060] exist Figure 18 In the present invention, the on / off timing of the sensor driving pulse SP is within the pulse width T11 of the light source lighting pulse PL, but the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com