Method for depositing mercury in water body and application thereof

A mercury deposition, water body technology, applied in the field of water treatment, to achieve the effect of accurate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

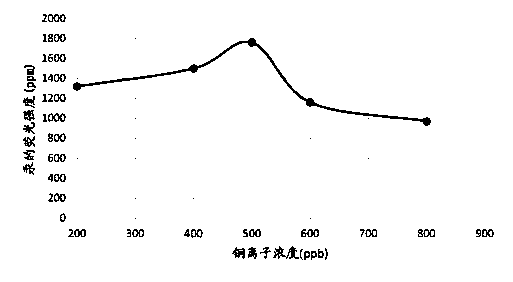

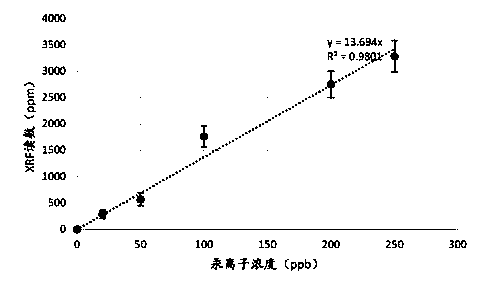

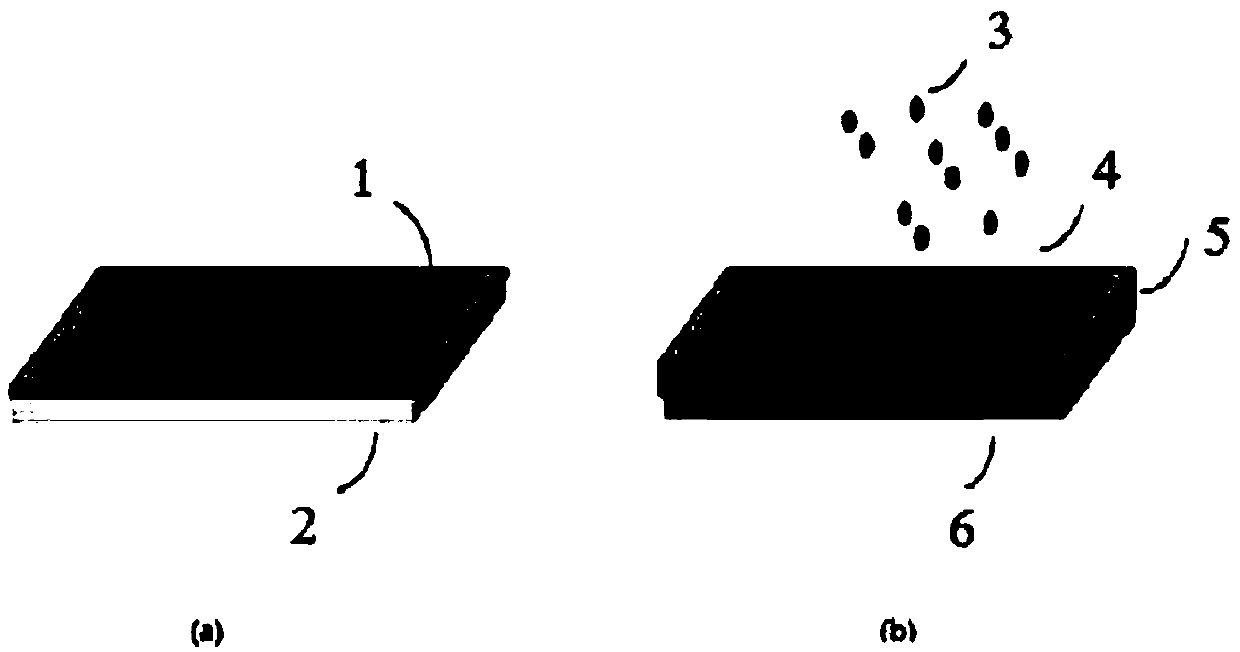

[0100] Take mercury standard solution (concentration of mercury ion standard solution is 1000ppm) and configure mercury ion concentration as 20ppb, 50ppb, 100ppb water body 6000ml, add CuCl 2 Make Cu 2+ The concentration is 500ppb, and the pH of the system is brought to 4.3 by using HAc / NaAc buffer solution. Immerse the Pt anode and graphite cathode in the water body, apply a 64V DC voltage, and start the electrochemical reaction, and mercury is deposited on the graphite cathode in the form of copper amalgam. After 1.5 hours, the electrochemical reaction was terminated, and the graphite cathode was taken out. A thick copper amalgam layer ( figure 1 (b) shows the Cu-Hg alloy layer deposited on the cathode in Example 3). Niton XL3t is used to carry out X-ray fluorescence spectrum measurement on graphite cathode, and the measurement results are as follows.

[0101] Example serial number

Embodiment 4-6

[0106] Take mercury standard solution (concentration of mercury ion standard solution is 1000ppm) and configure mercury ion concentration to be 20ppb, 50ppb, 100ppb water body 6000ml, add PbCl 2 making Pb 2+ The concentration is 500ppb, and the pH of the system is brought to 4.3 by using HAc / NaAc buffer solution. Immerse the Pt anode and the silicon cathode in the water body, apply a 64V DC voltage to start the electrochemical reaction, and mercury is deposited on the silicon cathode in the form of lead amalgam. After 1.5 hours, the electrochemical reaction was terminated, and the silicon cathode was taken out. Niton XL3t was used to perform X-ray fluorescence spectrometry on the silicon cathode, and the measurement results are as follows.

[0107] Example serial number

Embodiment 7

[0109] Get mercury standard solution (concentration of mercury ion standard solution is 1000ppm) configuration mercury ion concentration is the water body 6000ml of 50ppb, add ZnSO 4 making Zn 2+ The concentration is 500ppb, and the pH of the system is brought to 4.3 by using HAc / NaAc buffer solution. Immerse the Pt anode and the silicon cathode in the water body, apply a 64V DC voltage to start the electrochemical reaction, and mercury is deposited on the silicon cathode in the form of zinc amalgam. After 1.5 hours, the electrochemical reaction was terminated, and the silicon cathode was taken out. X-ray fluorescence spectroscopy of the silicon cathode was performed on a Niton XL3t, giving a reading of 1285 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com