Production assembly line of paper diapers

A technology for the production of assembly lines and diapers, which is applied in medical science, clothing, underwear, etc. It can solve the problems of SAP puncturing the bottom film and waste of SAP, and achieve the effects of prolonging service life, improving production efficiency, and stabilizing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

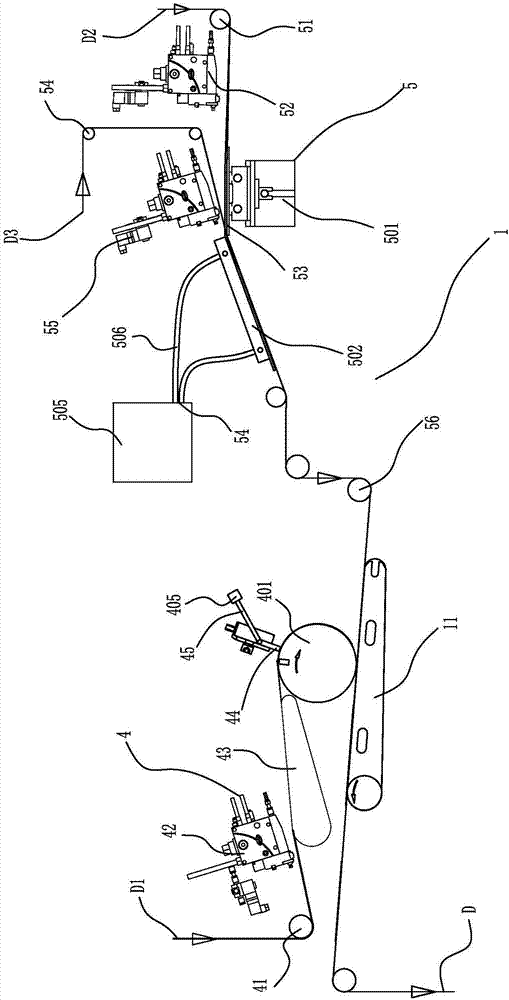

[0024] Below is the combination figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The technical scheme of the present invention is further described in detail.

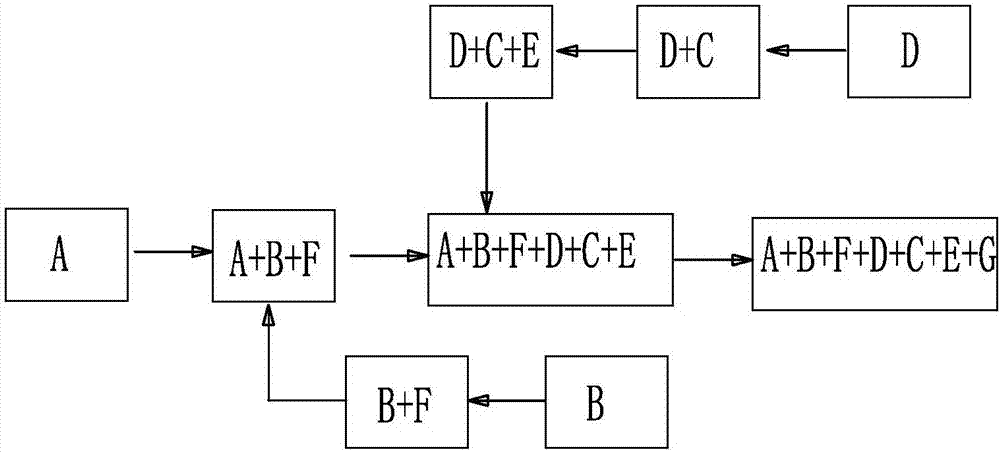

[0025] like figure 1 The principle block diagram of the production line production process of diapers is shown, where A is the core body, B is the bottom film, C is the surface non-woven fabric, D is the three-dimensional protection, E is the back elastic waist, F is the front waist sticker, G is for left and right stickers.

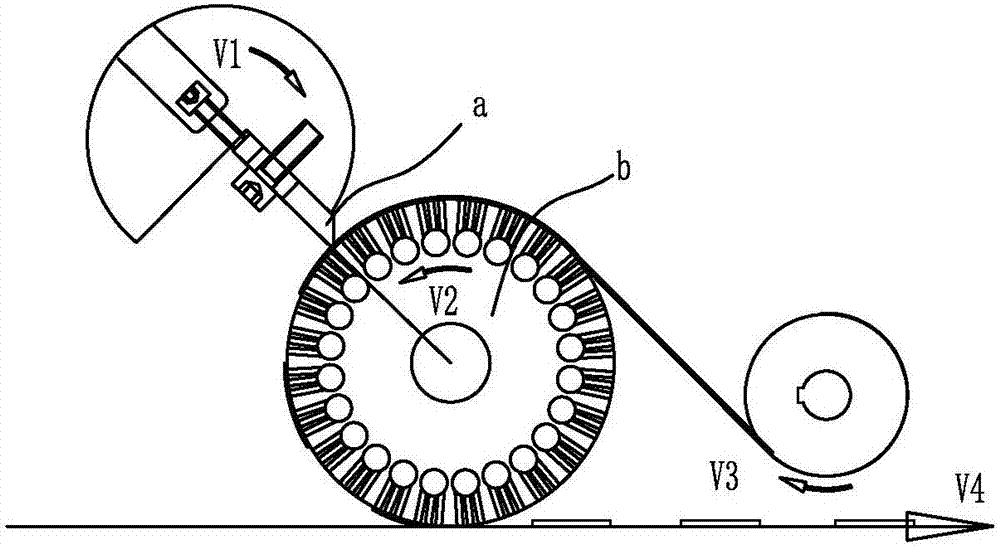

[0026] like figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The production line of diapers shown includes the frame and the core forming mechanism 6 on it, the surface layer non-woven fabric feeding device, the bottom film feeding device, the back wall non-woven fabric feeding device, the side non-woven fabric Feeding device, elastic feeding device, rear elastic wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com