Catalyst for synthesizing methanol by carbon dioxide hydrogenation and preparation and application thereof

A technology for carbon dioxide and methanol synthesis, which is applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, hydroxyl compound preparation, etc., can solve the problems of pH increase and catalyst activity reduction, and achieve good stability, The effect of increasing the conversion rate of carbon dioxide and increasing the yield of methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

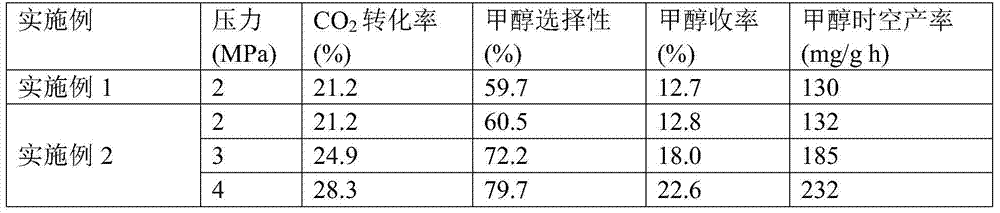

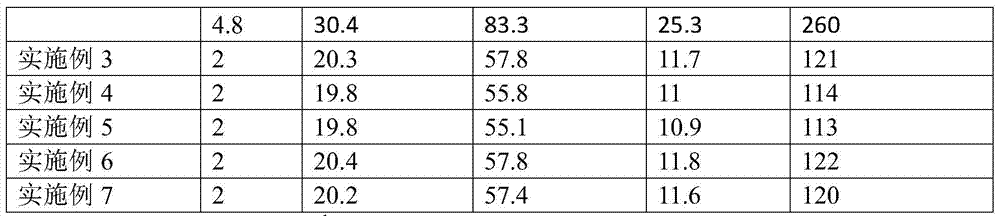

Examples

Embodiment 1

[0013] Weigh 18mmol Cu(NO 3 ) 2 ·3H 2 O, 9mmol Zn(NO 3 ) 2 ·6H 2 O, 2.1mmolAl(NO 3 ) 3 9H 2 O, 0.9mmol ZrO(NO 3 ) 2 2H 2 O is configured into 100mL aqueous solution, weigh 30mmolNa2CO 3 Configured as a 100mL aqueous solution, take 200mL deionized water and place it in a 500mL beaker, insert a pH meter, metal salt solution and Na 2 CO 3 The aqueous solution is co-precipitated at 70°C, the stirring speed is 600r / min, the pH is controlled at 7, and the precipitation speed is 3mL / min. After the precipitant is consumed, there is still about 20mL of the metal salt solution, and the obtained precipitation mother solution is aged at 70°C for 1h. During the aging process, use the remaining metal salt solution to adjust pH=7 for about 1 hour, cool, filter naturally, wash with deionized water for 5 times until the filtrate is free of sodium ions, filter with suction, dry at 60°C, and roast in air at 350°C for 4 hours to obtain Catalyst oxidation state precursor. Tablets wer...

Embodiment 2

[0016] The metal salt used is 18mmol Cu(NO 3 ) 2 ·3H 2 O, 6mmol Zn(NO 3 ) 2 ·6H 2 O, 3mmolAl(NO 3 ) 3 9H 2 O, 3mmol ZrO(NO 3 ) 2 2H 2 O, other steps are identical with embodiment 1.

Embodiment 3

[0018] Weigh 18mmol Cu(NO 3 ) 2 ·3H 2 O, 9mmol Zn(NO 3 ) 2 ·6H 2 O was prepared into 90mL aqueous solution, and 2.1mmol Al(NO 3 ) 3 9H 2 O, 0.9mmol ZrO(NO 3 ) 2 2H 2 O prepared into 10mL aqueous solution, weighed 32mmol Na2CO 3 Configured as a 107mL aqueous solution, take 200mL deionized water and place it in a 500mL beaker, insert a pH meter, AlZr metal salt solution and Na2CO 3 The aqueous solution was co-precipitated at 70°C, the stirring speed was 500r / min, the pH was controlled at 7, and the precipitation speed was 1.5mL / min. After the AlZr salt was consumed and aged for 0.5h, the CuZn salt solution was mixed with Na2CO 3 Co-precipitate the aqueous solution, control the pH=7, and stir at a speed of 600r / min. After the precipitant is exhausted, aging begins, and the remaining CuZn salt is used to continue adjusting pH=7 for about 1 hour. Other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com