Stacking manipulator based on radio frequency technology

A radio frequency technology and manipulator technology, applied in the field of palletizing machinery, can solve the problems of low efficiency and manpower consumption, achieve high social value, reduce the process and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

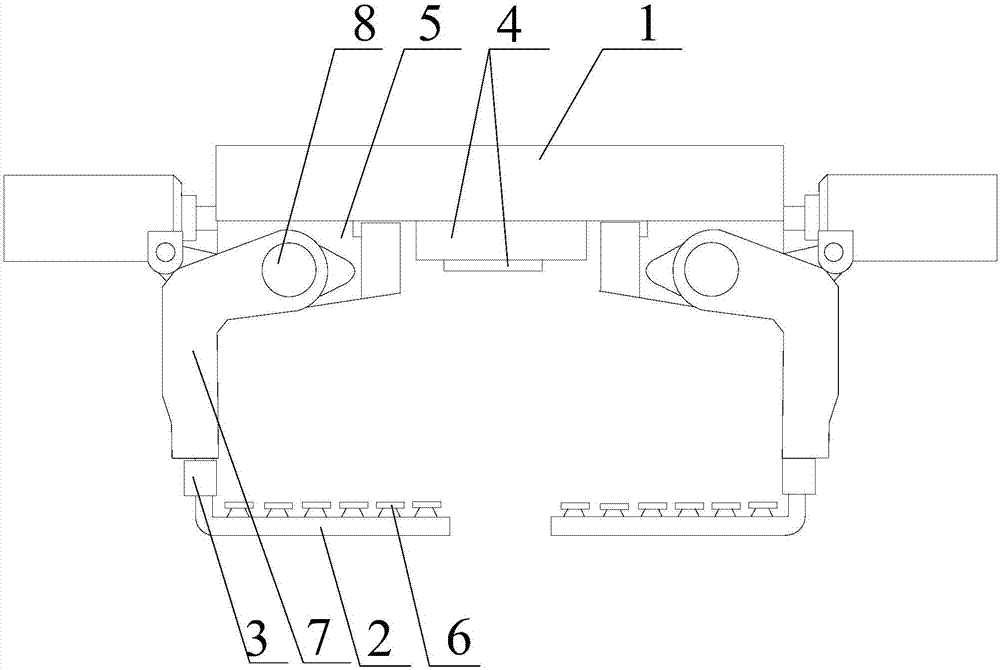

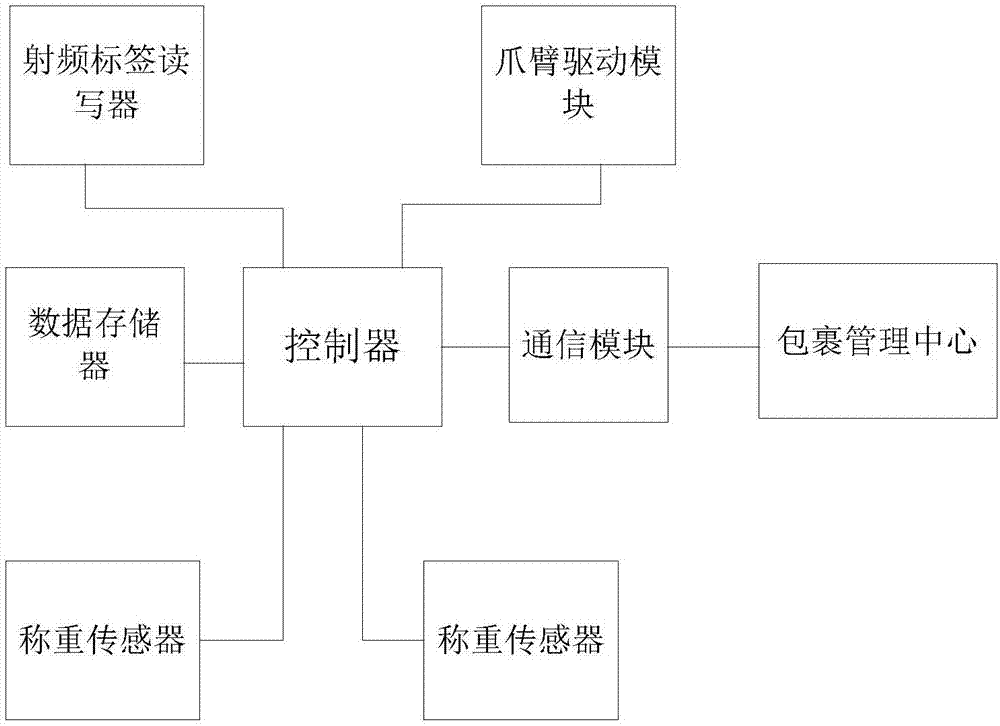

[0026] Such as figure 1 , 2 As shown, the palletizing manipulator based on radio frequency technology of the present invention includes a gripper frame 1, grippers 2 are respectively arranged at both ends of the gripper gripper 1, and a radio frequency sticker is arranged between the grippers 2. The package 8 of the label is provided with a load cell 3 on each gripper 2, and a radio frequency tag reader 4 is also arranged at the bottom of the gripper frame 1, and is also installed on the gripper frame 1. controller, data storage, of which:

[0027] RF tag reader 4: scan the RF tag, send the package information to the controller; receive the weight information transmitted by the controller, and send the weight information to the RF tag;

[0028] Load cell 3: Receive the weighing instruction sent by the controller, collect the weight information of the package 8 between the grippers 2, and send the weight information to the controller;

[0029] Controller: Receive the package...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com