Integrally-recoverable artificial lawn and preparation method thereof

A technology for artificial turf and artificial grass silk, which is applied in chemical instruments and methods, textiles and papermaking, and other household appliances, etc. The effect of maintaining compound difficulty, ensuring integrity, and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] 1. Preparation method of artificial turf

[0066] (1) 50 parts of 5000S resin, 40 parts of 7042 resin, 8 parts of color masterbatch, 2 parts of processing aids (including UV stabilizer, antioxidant, antistatic agent, blocking agent, dispersant), and mix well;

[0067] (2) The extrusion molding temperature is controlled at 190°C-230°C, the draft ratio is set at 5-6, the oven temperature is controlled at 95-100°C, extruded and drawn by a single-screw extruder to prepare artificial grass.

[0068] 2. The heat treatment of mesh cloth, non-woven fabric or composite cloth of non-woven fabric and mesh cloth has the following methods:

[0069] (1) Oven heating, temperature 170-175 ℃, line speed about 13m / min;

[0070] (2) Oven heating, temperature 180-185 ℃, line speed about 15m / min;

[0071] (3) Heated by hot roller, the temperature is 185-190°C, and the line speed is about 4.5m / min;

[0072] (4) The hot roller is heated, the temperature is 195-200°C, and the line speed is ab...

Embodiment 1

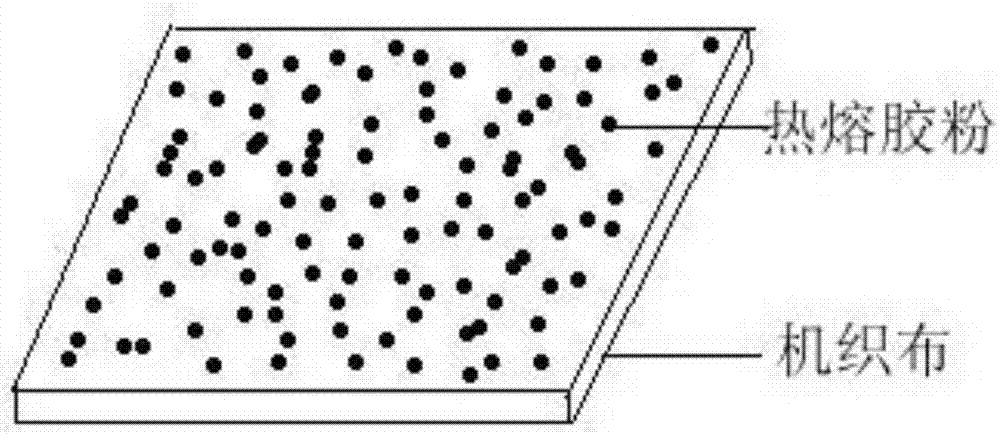

[0079] (1) According to 80g / m 2 Sprinkle the amount of powder evenly sprinkle PE hot melt adhesive powder in 200g / m 2 The PP single-layer woven fabric is heated in an oven, and the temperature is controlled at 130-140°C. The hot-melt adhesive powder melts and sticks to the woven fabric, and then cooled and shaped to make the base fabric.

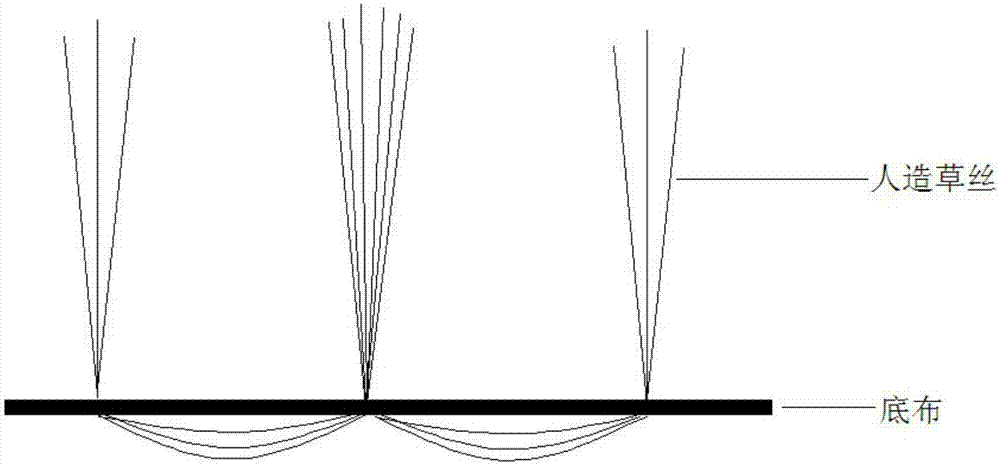

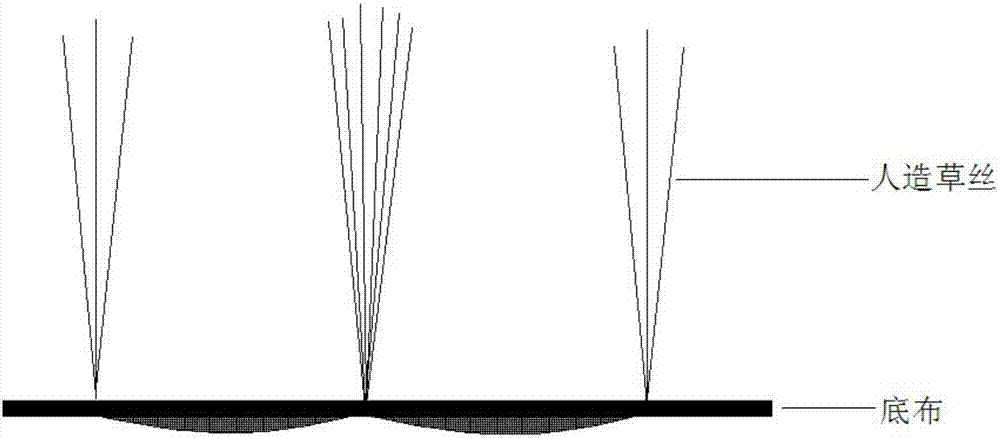

[0080] (2) The artificial turf is tufted on the base fabric to make a semi-finished artificial turf (with hot melt adhesive powder as the bottom surface), and then the bottom surface of the semi-finished product is heated by a hot roller. The heating temperature is controlled at 150-160°C. The roots and the hot-melt adhesive powder are melted, stuck together, cooled, shaped, and the overall recyclable artificial turf is obtained.

[0081] (3) Test the pull-out force of the artificial turf and the breaking force of the artificial turf bottom, see attached table 1 for the results.

Embodiment 2

[0083] (1) According to 120g / m 2 Sprinkle the amount of powder evenly sprinkle PE hot melt adhesive powder in 150g / m 2 The PP single-layer woven fabric is heated in an oven, and the temperature is controlled at 130-140°C. The hot-melt adhesive powder melts and sticks to the woven fabric, and then cooled and shaped to make the base fabric.

[0084] (2) The artificial turf is tufted on the base fabric to make a semi-finished artificial turf (with hot melt adhesive powder as the bottom surface), and then the bottom surface of the semi-finished product is heated by a hot roller. The heating temperature is controlled at 150-160°C. The roots and the hot-melt adhesive powder are melted, stuck together, cooled, shaped, and the overall recyclable artificial turf is prepared.

[0085] (3) Test the pull-out force of the artificial turf and the breaking force of the artificial turf bottom, see attached table 1 for the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com