Sulfonated tannin extract and preparation method thereof

A technology for sulfonated tannin extract and tannin extract, which is applied in the field of sulfonated tannin extract and its preparation, can solve the problems of low sulfonation efficiency and further improvement of compatibility effect, and achieve the effects of low pollution, high compatibility effect and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

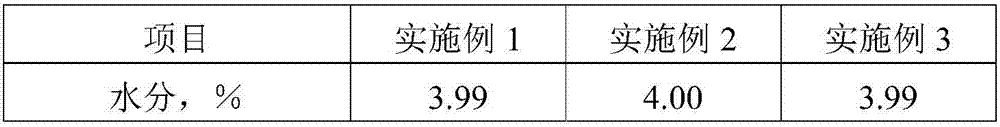

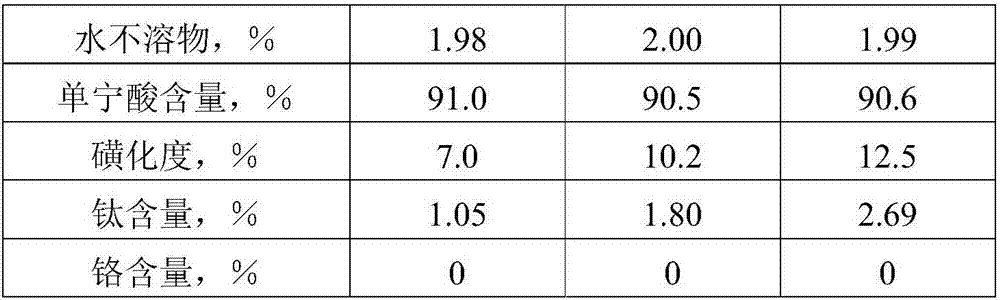

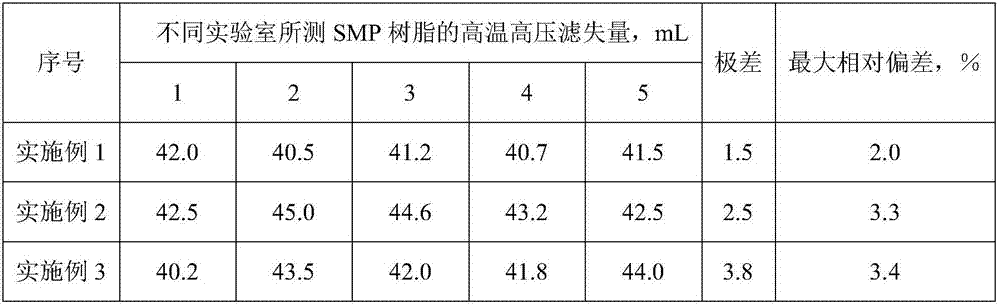

Embodiment 1

[0038] The sulfonated tannin extract of this embodiment is prepared by the following steps:

[0039] 1) Add 100g of tannin extract powder to 900g of deionized water at 65°C under stirring, heat and stir for 30min, then let stand for 24h and then filter, discard the insoluble matter to obtain a purified solution;

[0040] 2) Add 30 g of sodium hydroxide to the purified solution, then add 5 g of formaldehyde solution with a mass concentration of 30%, and react at 90° C. for 0.5 h to obtain a methylation solution;

[0041] 3) Add 8 g of sodium bisulfite to the methylation solution, and react at 90° C. for 4 hours to obtain a sulfonation solution;

[0042] 4) Add 1 g of titanium sulfate solution with a mass concentration of 25% to the sulfonation solution, react at 90° C. for 0.5 h, concentrate and granulate to obtain sulfonated tannin extract for SMP resin quality evaluation test.

Embodiment 2

[0044] The sulfonated tannin extract of this embodiment is prepared by the following steps:

[0045] 1) Add 100g of tannin extract powder to 1000g of deionized water at 60°C under stirring, heat and stir for 30min, then let stand for 24h and then filter, discard the insoluble matter to obtain a purified solution;

[0046] 2) Add 30 g of sodium hydroxide to the purified solution, then add 6 g of formaldehyde solution with a mass concentration of 30%, and react at 90° C. for 0.5 h to obtain a methylation solution;

[0047] 3) Add 9 g of sodium bisulfite to the methylation solution, and react at 90° C. for 4 hours to obtain a sulfonation solution;

[0048] 4) Add 2 g of titanium sulfate solution with a mass concentration of 30% to the sulfonation solution, react at 90° C. for 0.5 h, concentrate and granulate to obtain sulfonated tannin extract for SMP resin quality evaluation test.

Embodiment 3

[0050] The sulfonated tannin extract of this embodiment is prepared by the following steps:

[0051] 1) Add 100g of tannin extract powder to 1200g of deionized water at 70°C under stirring, heat and stir for 30min, let stand for 24h, filter, discard insoluble matter, and obtain a purified solution;

[0052] 2) Add 30 g of sodium hydroxide to the purified solution, then add 7 g of formaldehyde solution with a mass concentration of 30%, and react at 90° C. for 0.5 h to obtain a methylation solution;

[0053] 3) Add 10 g of sodium bisulfite to the methylation solution, and react at 90° C. for 4 hours to obtain a sulfonation solution;

[0054] 4) Add 3 g of titanium sulfate solution with a mass concentration of 30% to the sulfonation solution, react at 90° C. for 0.5 h, concentrate and granulate to obtain sulfonated tannin extract for SMP resin quality evaluation test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com