Mobile lifting device of disk bale plucker

A technology of disc catching machine and lifting device, which is applied in the direction of bale opening machine, etc., which can solve the problems of affecting cotton grabbing efficiency, cotton material cannot be sucked, and poor adjustment flexibility, etc., so as to improve grabbing efficiency and grabbing Quality, increased range and flexibility, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

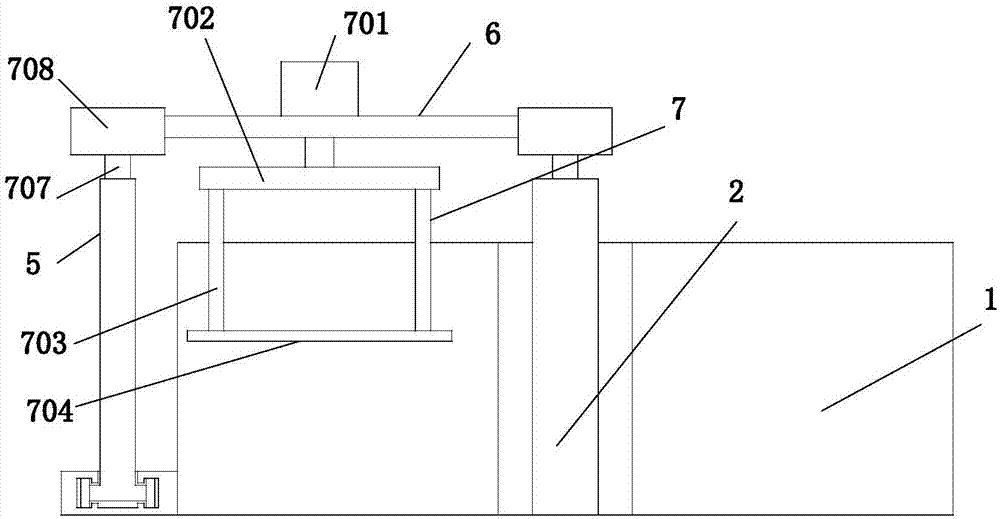

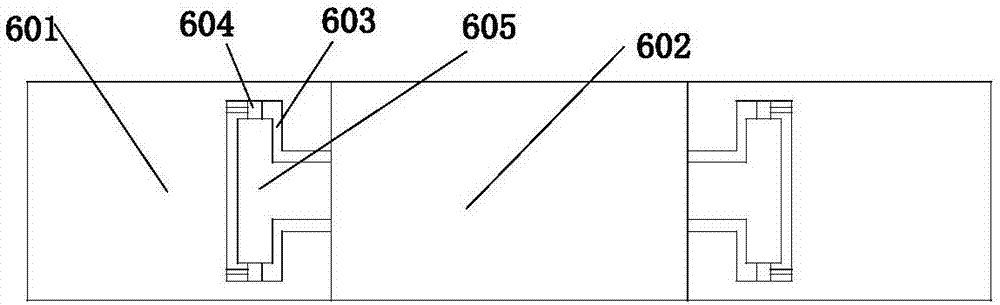

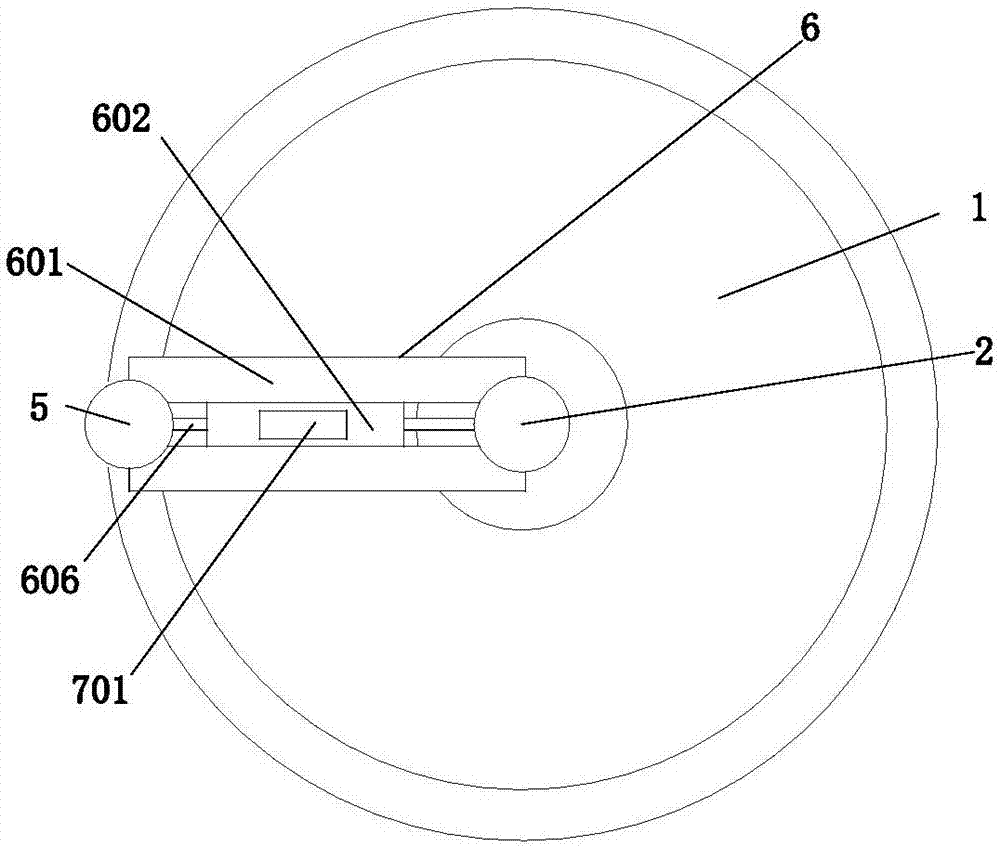

[0016] Example. A mobile lifting device of a disc plucking machine, constituted as Figure 1 to Figure 4 As shown, it includes a rotating column 2 and a driving column 5 arranged on the inner and outer sides of the annular silo 1. A supporting sliding device 6 is provided between the rotating column 2 and the driving column 5, and a lifting device is provided on the supporting sliding device 6. 7. The supporting sliding device 6 includes two supporting plates 601 arranged between the driving column 5 and the rotating column 2, a sliding plate 602 is arranged between the two supporting plates 601, and the two supporting plates 601 are opposite to each other. A T-shaped chute 603 is provided on the side wall of the T-shaped chute 603, and a pulley 604 is arranged in the T-shaped chute 603. T-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com