Automatic warp knitting batching system and replacing method for batch and batching drum

A technology of automatic cloth roll and cloth roll, which is applied in warp knitting, textiles, papermaking, knitting, etc., and can solve the problems of unbalanced alignment of warp knitted fabric ends, large space occupied by the roll roll, and uneven warp knitted fabric Unevenness and other problems can be achieved to improve the quality of coiling, improve the volume and quality of coiled cloth, and facilitate the effect of brushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

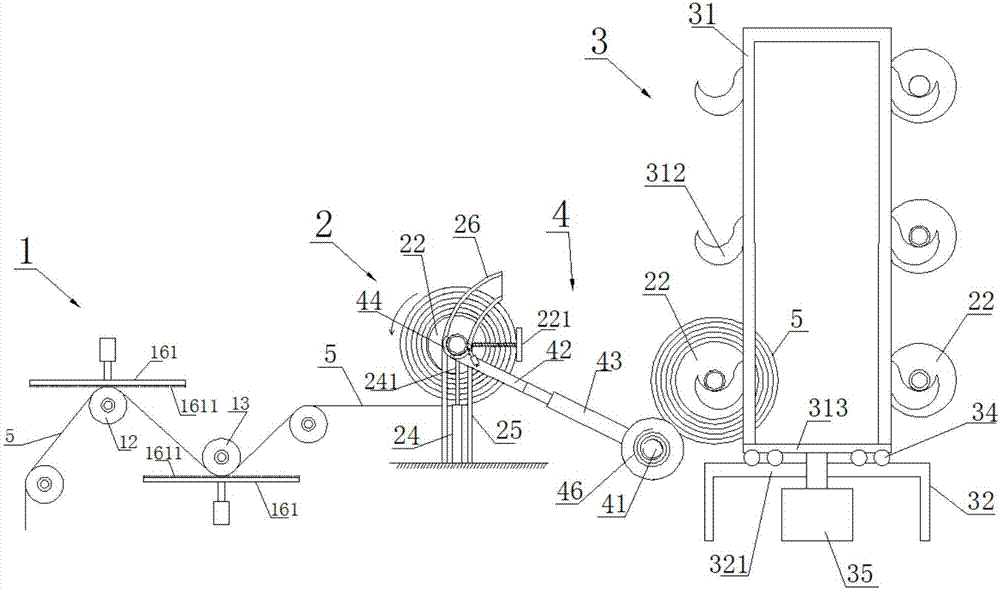

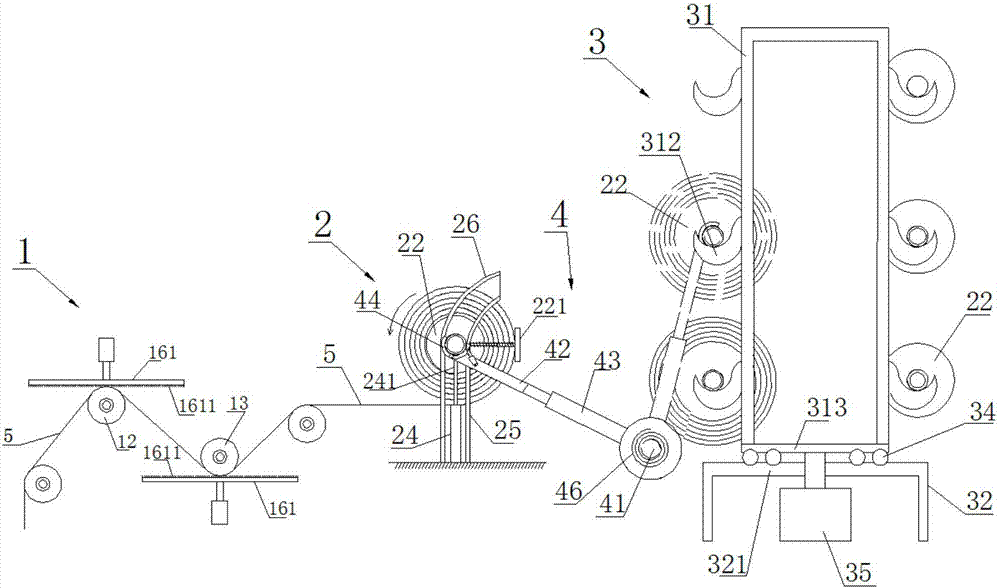

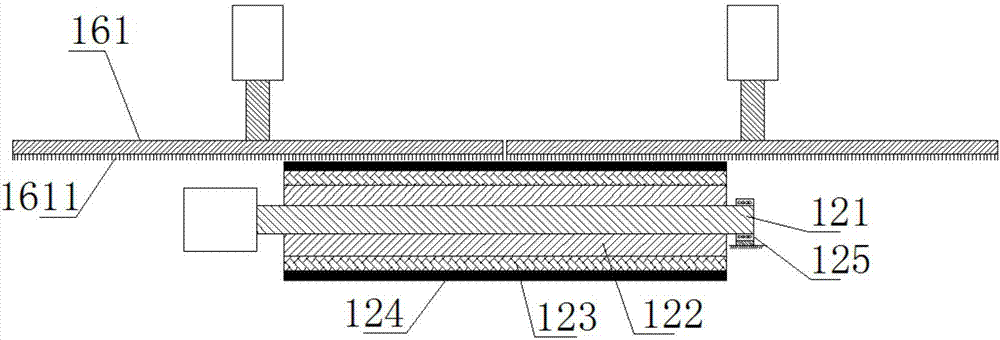

[0039] like Figures 1 to 5 , shown in 7 to 9, an automatic cloth rolling system for warp knitted cloth, including a cloth flattening device 1, a cloth rolling device 2 and a placement frame 3 arranged in sequence; The first roller 12 and the second roller 13 that are dislocated up and down and arranged horizontally; the structure of the first roller 12 and the second roller 13 is the same; the cloth 5 goes around the upper end of the first roller 12 and the lower end of the second roller 13 in turn; A brush leveling device is respectively arranged above the roller 12 and below the second roller 13, which can realize the brushing of the upper and lower sides of the cloth 5; The opposite side of the rotating disk 161 and the cloth 5 is densely provided with bristles 1611; the bristles 1611 are in contact with the cloth 5, and the rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com