Color steel sandwich plate

A technology of sandwich panels and color steel plates, applied in special buildings, small buildings, building components, etc., can solve the problems of flammability of polyurethane, deformation of color steel plates, short service life of color steel sandwich panels, etc., to achieve anti-corrosion Improved impact resistance, waterproof performance, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

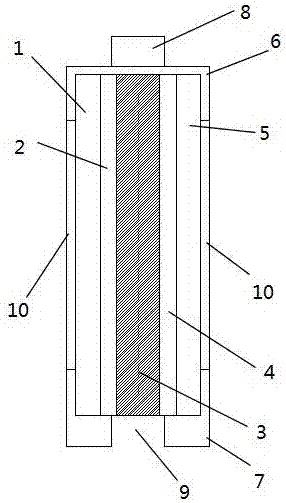

[0023] Embodiment 1: A color steel sandwich panel, the color steel sandwich panel is provided with a first color steel plate, a first silica airgel layer, a foam glass layer, a second silica Airgel layer, the second color steel plate; the first silica airgel layer and the second silica airgel layer are provided with reinforcing materials along the vertical color steel sandwich panel; the color steel sandwich An upper positioning splint and a lower positioning splint are respectively provided on the upper and lower sides of the plate; a flange is provided on the upper positioning splint; a groove for placing the flange is provided on the lower positioning splint.

Embodiment 2

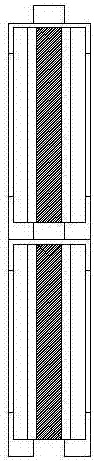

[0024] Embodiment 2: A color steel sandwich panel, the color steel sandwich panel is provided with a first color steel plate, a first silica airgel layer, a foam glass layer, a second silica Airgel layer, the second color steel plate; the first silica airgel layer and the second silica airgel layer are provided with reinforcing materials along the vertical color steel sandwich panel; the color steel sandwich The upper and lower sides of the plate are respectively provided with an upper positioning splint and a lower positioning splint; the upper positioning splint is provided with a flange; the lower positioning splint is provided with a groove for placing the flange, and the first color steel plate and the second An organic coating is provided on the outside of the two-color steel plate, and the organic coating is a polyether ether ketone coating.

Embodiment 3

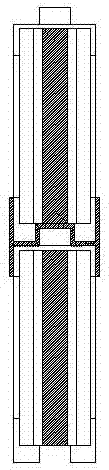

[0025] Embodiment 3: A color steel sandwich panel, the color steel sandwich panel is provided with a first color steel plate, a first silica airgel layer, a foam glass layer, a second silica Airgel layer, the second color steel plate; the first silica airgel layer and the second silica airgel layer are provided with reinforcing materials along the vertical color steel sandwich panel; the color steel sandwich The upper and lower sides of the board are respectively provided with an upper positioning splint and a lower positioning splint; the upper positioning splint is provided with a flange; the lower positioning splint is provided with a groove for placing the flange, and the color steel sandwich panel is also It includes an installation connecting plate; the installation connecting plate is composed of two auxiliary plates clamping a support plate; the support plate is vertically arranged in the middle of the two auxiliary plates; a U-shaped groove is provided on the support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com