Permanent magnet motor controller used for electrolytic capacitor-free motor drive system and method

A motor drive system and electrolytic capacitor technology, applied in motor generator control, electronic commutation motor control, AC motor control, etc., can solve the problems of DC bus voltage fluctuation and small capacitance value, and achieve stable output and suppress fluctuation. , the effect of reducing the volatility coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

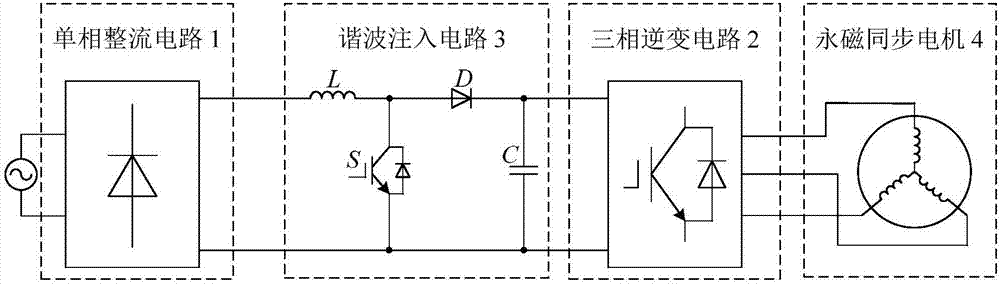

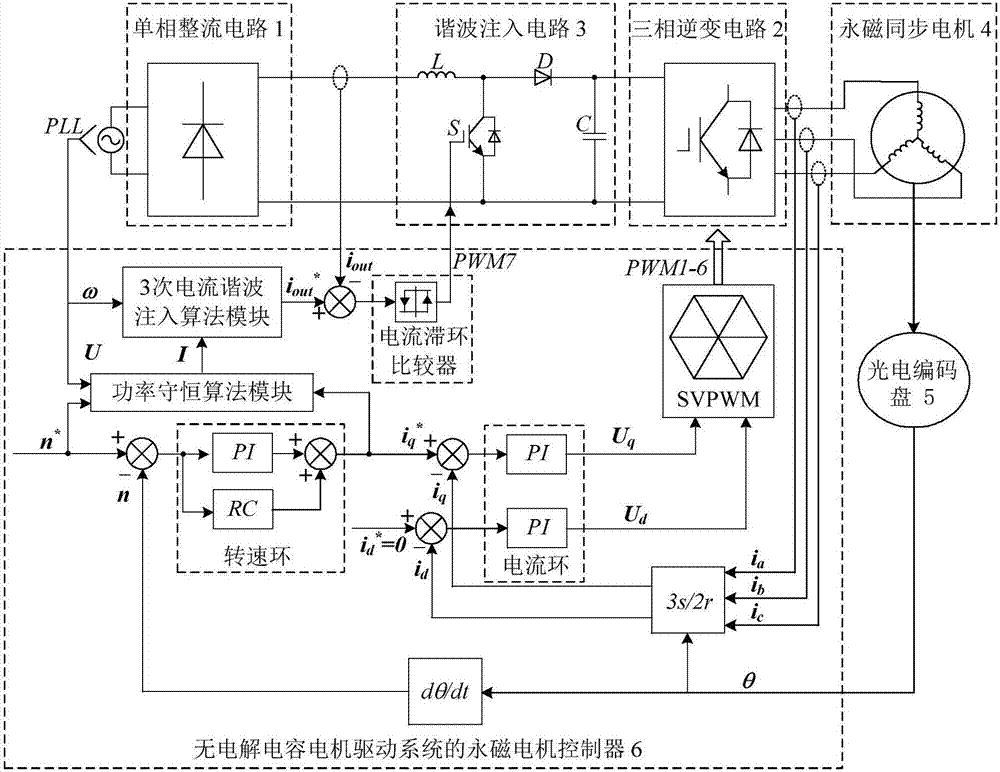

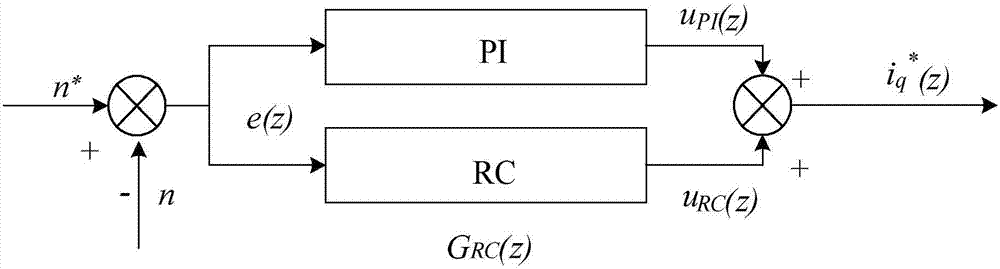

[0020] see figure 2 , The motor drive system without electrolytic capacitors is composed of a single-phase rectifier circuit 1, a harmonic injection circuit 3 and a three-phase inverter circuit 2 connected in series in sequence, and the three-phase inverter circuit 2 drives the permanent magnet synchronous motor 4. The output terminals of the permanent magnet motor controller 6 used in the electrolytic capacitor motor drive system according to the present invention are respectively connected to the harmonic injection circuit 3 and the three-phase inverter circuit 2 of the electrolytic capacitor motor drive system. The permanent magnet motor controller 6 is composed of the third-order current harmonic injection algorithm module, power conservation algorithm module, current hysteresis comparator, speed loop, current loop, 3s / 2r coordinate transformation module, dθ / dt calculation module and SVPWM modulation module .

[0021] The rotor position angle θ of the permanent magnet sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com