A dry powder mortar production equipment and process

A technology of dry powder mortar and production equipment, which is applied in the field of dry powder mortar, can solve problems such as excessive dust and poor production environment, and achieve the effects of improving the working environment, reducing the adhesion rate, and setting up scientifically and reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

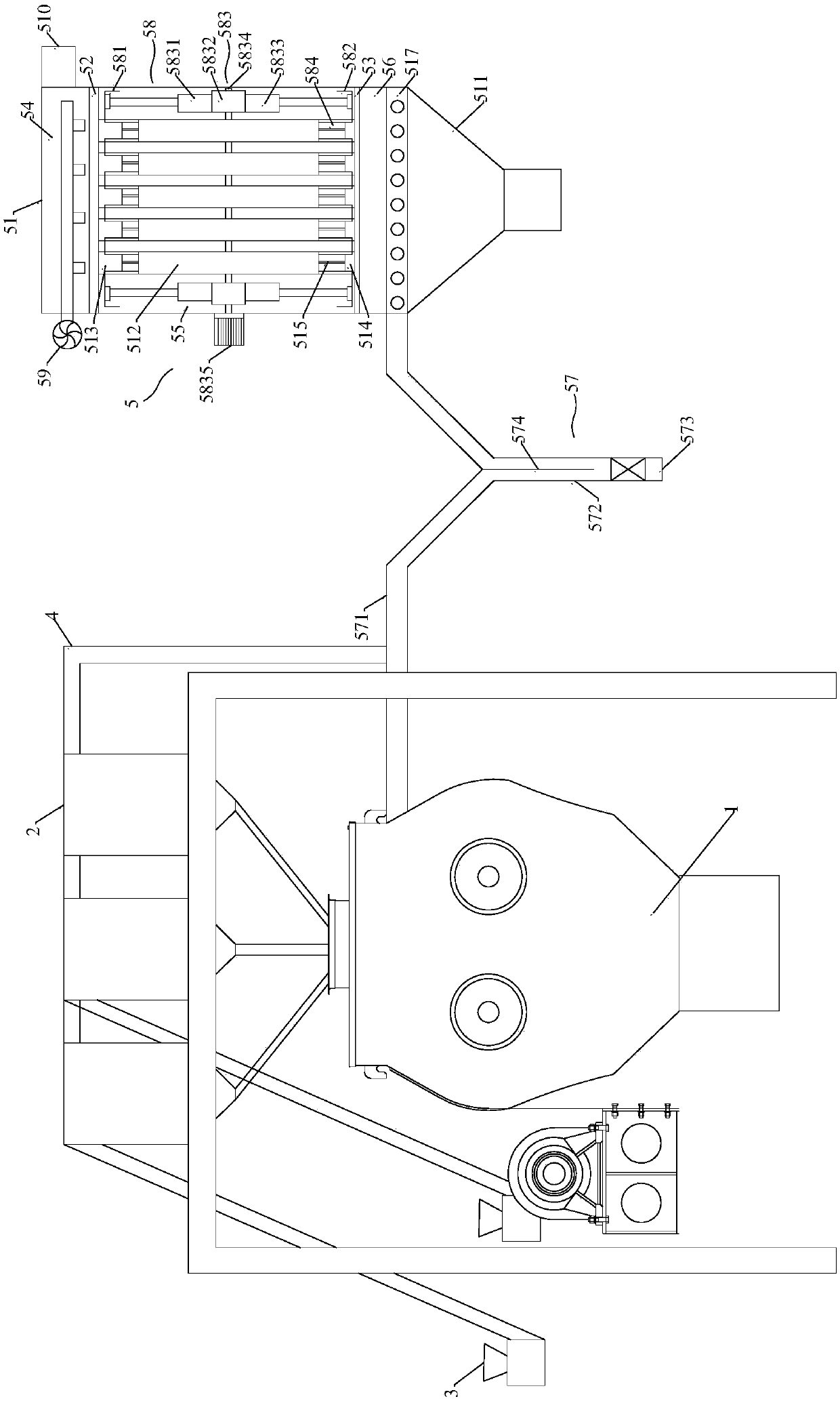

Embodiment 1

[0078] Put different dry powder materials in different storage bins; transport various dry powder materials from the storage bin to mixer 1 according to the addition ratio; stir different dry powder materials first, and then carry out the second stirring after an interval of 25 minutes. First stirring, wherein the stirring time of the first stirring and the second stirring are 40 minutes and 1 hour respectively, to make dry powder mortar. The dust generated during production passes through the condenser to reduce the dust temperature to 20°C, and then is sent to the bag filter 5 for dust removal. And the working temperature is maintained at 20°C during production. After testing, the AQI index of the working environment in the production process is maintained at 71-115, and the final product is relatively uniform.

Embodiment 2

[0080] Put different dry powder materials in different storage bins; transport various dry powder materials from the storage bin to mixer 1 according to the addition ratio; stir different dry powder materials first, and then carry out the second stirring after an interval of 35 minutes. First stirring, wherein the stirring time of the first stirring and the second stirring are 40 minutes and 1 hour respectively, to make dry powder mortar. The dust generated during production passes through the condenser to reduce the dust temperature to 20°C, and then is sent to the bag filter 5 for dust removal. And the working temperature is maintained at 20°C during production. After testing, the AQI index of the working environment in the production process is maintained at 63-85, and the final product is relatively uniform.

Embodiment 3

[0082] Put different dry powder materials in different storage bins; transport various dry powder materials from the storage bin to mixer 1 according to the addition ratio; stir different dry powder materials first, and then carry out the second stirring after an interval of 45 minutes. First stirring, wherein the stirring time of the first stirring and the second stirring are 40 minutes and 1 hour respectively, to make dry powder mortar. The dust generated during production passes through the condenser to reduce the dust temperature to 20°C, and then is sent to the bag filter 5 for dust removal. And the working temperature is maintained at 20°C during production. After testing, the AQI index of the working environment in the production process is maintained at 72-102, and the final product is relatively uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com