Medium-low speed magnetic levitation engineering work vehicle

A work vehicle and maglev technology, applied in the field of rail vehicles, can solve the problems of high noise, small turning radius, and difficult to reach the work vehicle, achieve a good guiding effect, and ensure the effect of forward and reverse driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

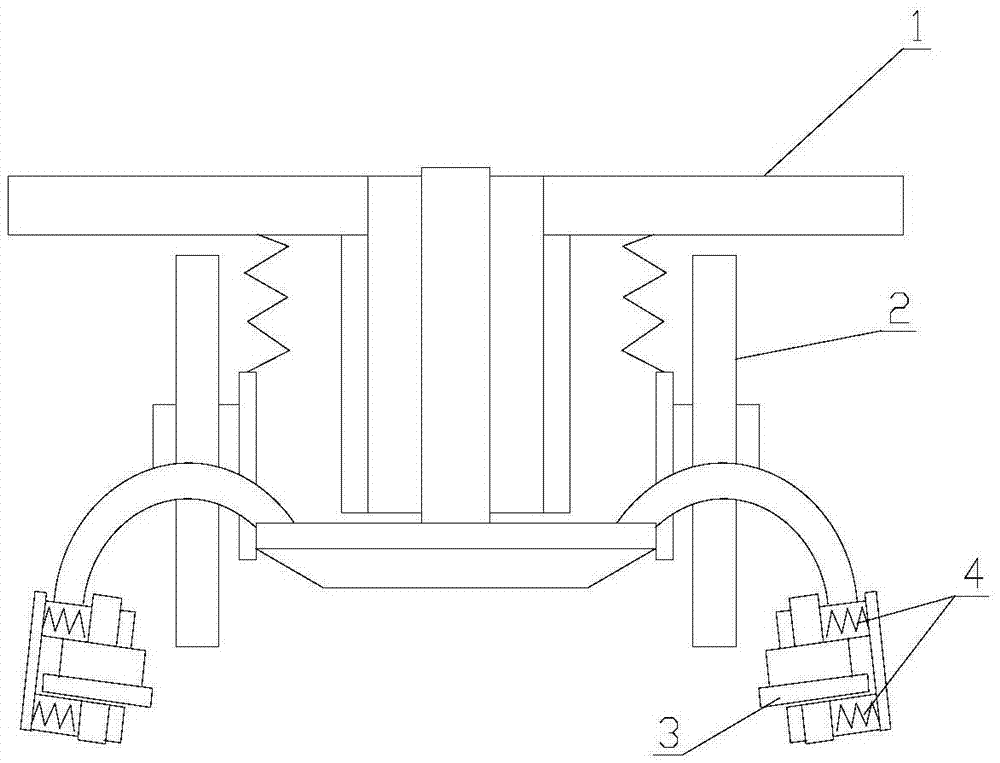

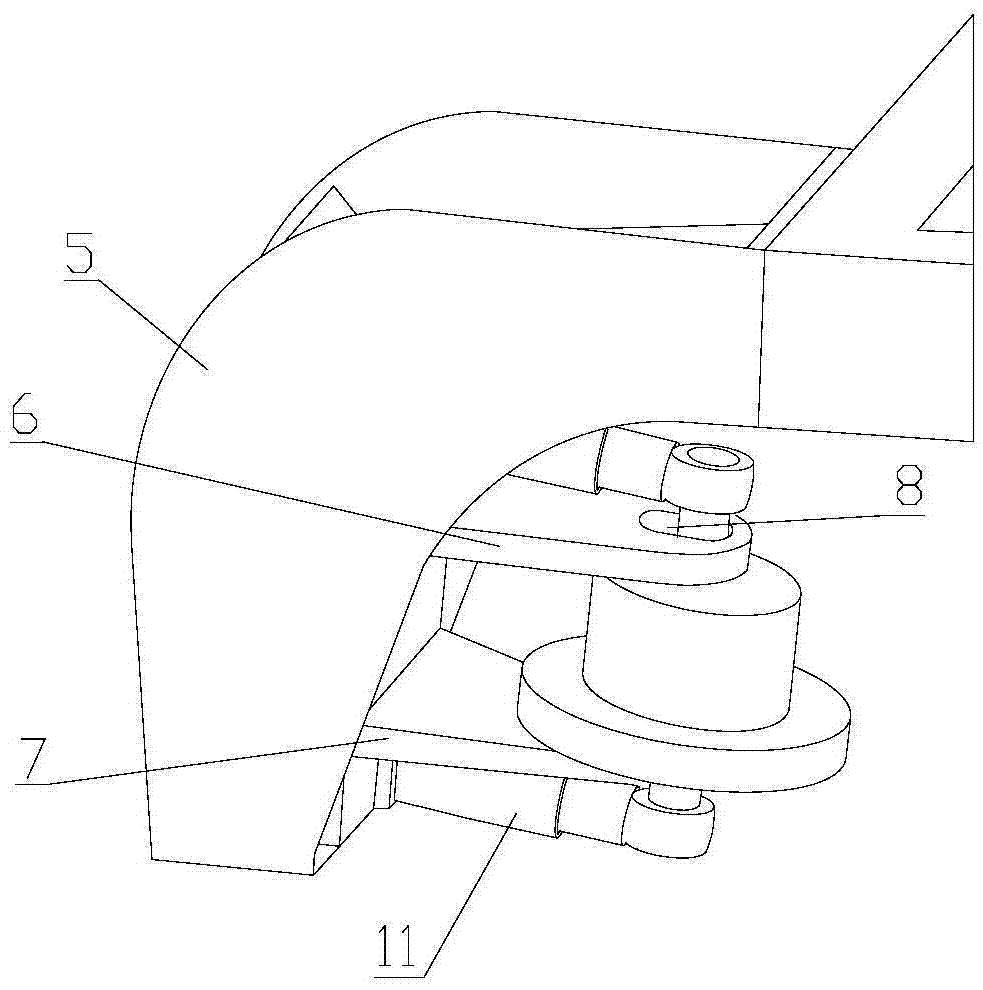

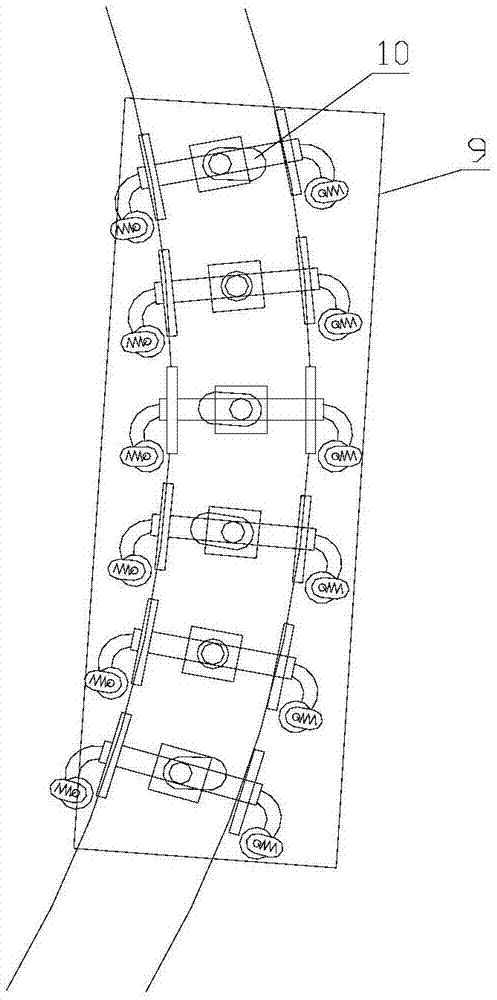

[0046] Please refer to figure 1 , figure 2 , figure 1 It is a structural schematic diagram of a specific embodiment of a medium-low speed maglev engineering operation vehicle provided by the present invention; figure 2 for figure 1 A partial schematic diagram of the guiding mechanism shown in .

[0047] As shown in the figure, in a specific implementation mode, the bogie of the medium and low-speed maglev engineering operation vehicle provided by the present invention refers to the railway running vehicle, and uses aluminum alloy wheel sets to realize running. Considering that the material of the F-type track is Q235B, the physical properties of the track material The performance is very common. Starting from the weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com