Plural gel containing phycoerythrin, preparation method and application

A phycoerythrin and composite gel technology, applied in the chemical field, can solve the problems of low photoelectric conversion efficiency of dye-sensitized cells, protein denaturation, and application difficulties, and achieve simple separation and purification, low cost, and high sample purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

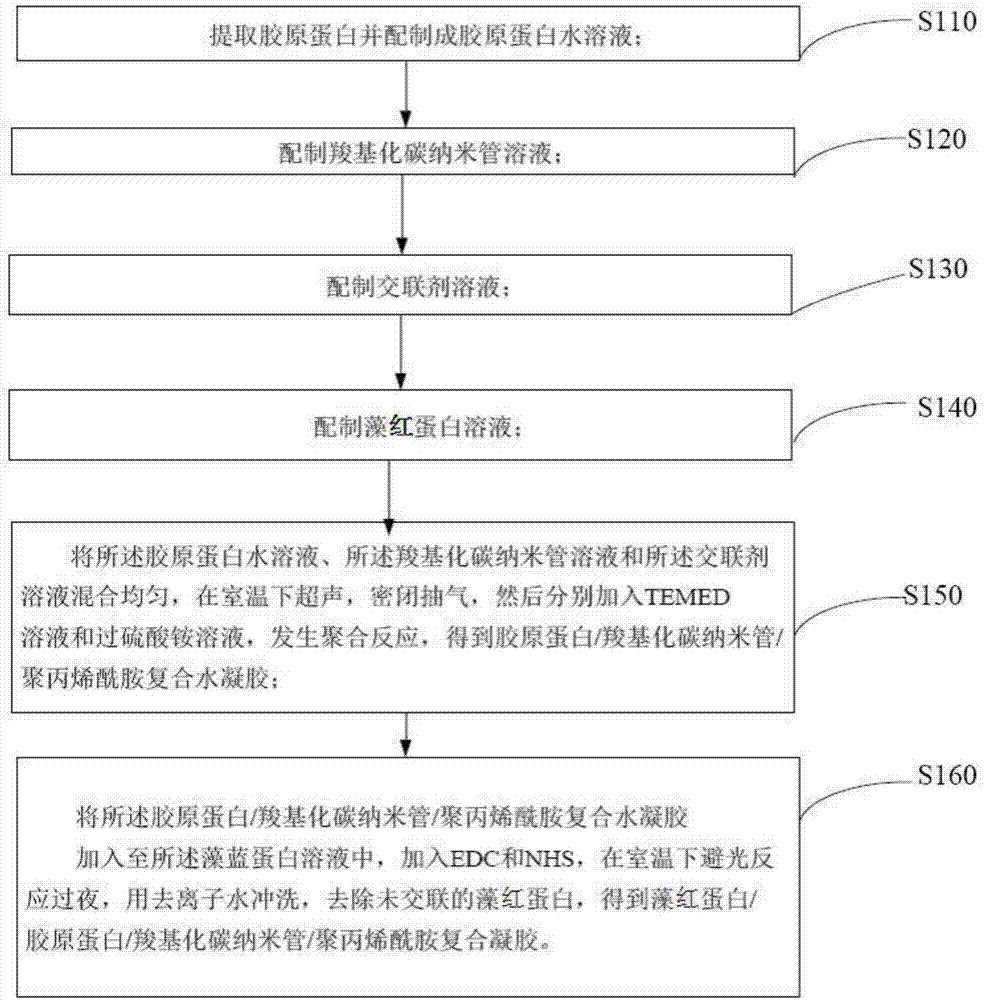

[0038]A preparation method of phycoerythrin / collagen / carboxylated carbon nanotube / polyacrylamide composite gel, comprising the steps of:

[0039] (1) Extracting collagen and preparing an aqueous collagen solution with a concentration of 5 mg / mL;

[0040] Take the fish skin and soak it in NaOH aqueous solution with a concentration of 0.2mol / L for 24 hours to remove non-collagen components. After washing to neutrality, add acetic acid solution with a concentration of 0.6mol / L to homogenate, extract with magnetic stirring at 4°C for 2 days, and centrifuge at 12000g for 30 minutes , add NaCl to the supernatant, centrifuge, collect and dissolve the precipitate in 0.5 mol / L acetic acid solution, dialyze with 0.1 mol / L acetic acid solution overnight, then dialyze with distilled water for 1 day, and freeze-dry to obtain acid-soluble fish collagen. Take acidic fish collagen and dissolve it in deionized water, adjust the pH to 6.0 with NaOH, and adjust the concentration of fish collagen...

Embodiment 2

[0050] A preparation method of phycoerythrin / collagen / carboxylated carbon nanotube / polyacrylamide composite gel, comprising the steps of:

[0051] (1) Extracting collagen and preparing an aqueous collagen solution with a concentration of 6 mg / mL;

[0052] Take the fish skin and soak it in 0.3mol / L NaOH aqueous solution for 14 hours to remove non-collagen components, wash it until neutral, add 0.4mol / L acetic acid solution for homogenization, extract with magnetic stirring at 4°C for 1 day, and centrifuge at 12000g for 30 minutes , add NaCl to the supernatant, centrifuge, collect and dissolve the precipitate in 0.6 mol / L acetic acid solution, dialyze with 0.1 mol / L acetic acid solution overnight, then dialyze with distilled water for 1 day, and freeze-dry to obtain acid-soluble fish collagen. Dissolve the acidic fish collagen into deionized water, adjust the pH to 6.0 with NaOH, and adjust the fish collagen concentration to 6 mg / ml.

[0053] (2) preparation concentration is th...

Embodiment 3

[0063] A preparation method of phycoerythrin / collagen / carboxylated carbon nanotube / polyacrylamide composite gel, comprising the steps of:

[0064] (1) Extracting collagen and preparing an aqueous collagen solution with a concentration of 7 mg / mL;

[0065] Take the fish skin and soak it in 0.1mol / L NaOH aqueous solution for 48 hours to remove the non-collagen components. After washing to neutrality, add 0.5mol / L acetic acid solution for homogenization, extract with magnetic stirring at 4°C for 2 days, and centrifuge at 12000g for 30 minutes , add NaCl to the supernatant, centrifuge, collect and dissolve the precipitate in 0.8 mol / L acetic acid solution, dialyze with 0.1 mol / L acetic acid solution overnight, then dialyze with distilled water for 2 days, and freeze-dry to obtain acid-soluble fish collagen. Dissolve the acidic fish collagen into deionized water, adjust the pH to 6.0 with NaOH, and adjust the fish collagen concentration to 7 mg / ml.

[0066] (2) preparation concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Performance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com