Blood collecting tube automatic coating machine with ultrasonic atomization mechanism

A technology of ultrasonic atomization and blood collection tube, which is applied to spray devices, liquid spray devices, etc., can solve problems such as falling crystals, and achieve the effect of ensuring the stability of the amount, the uniform coating, and the accuracy of the spray amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

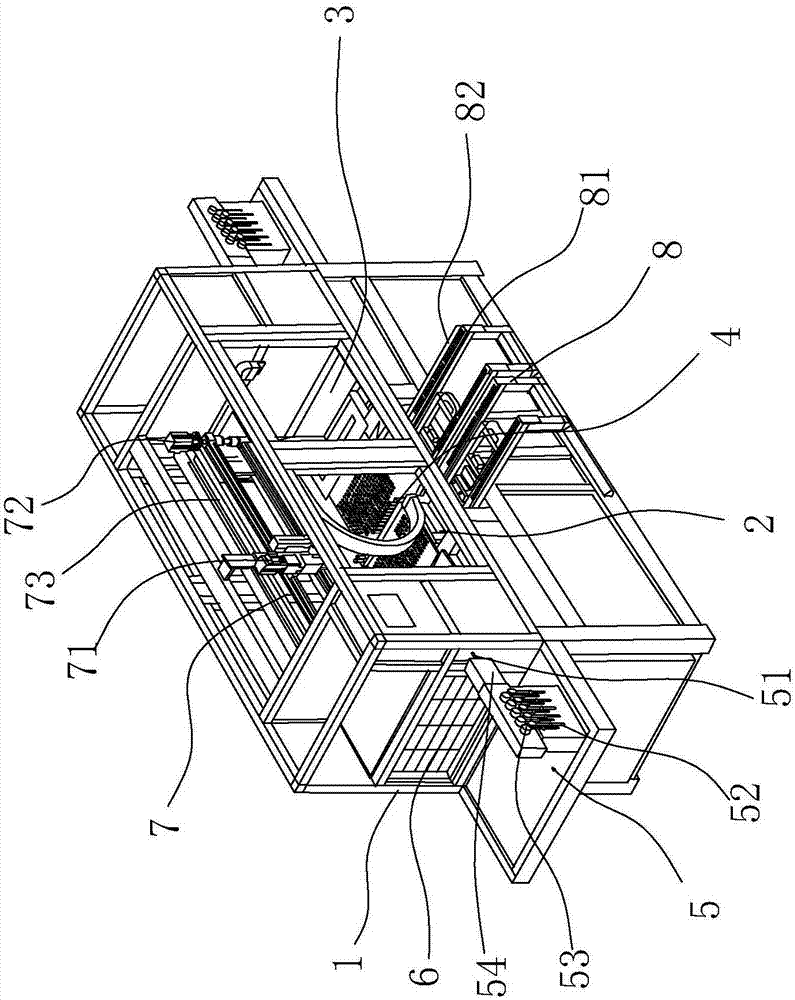

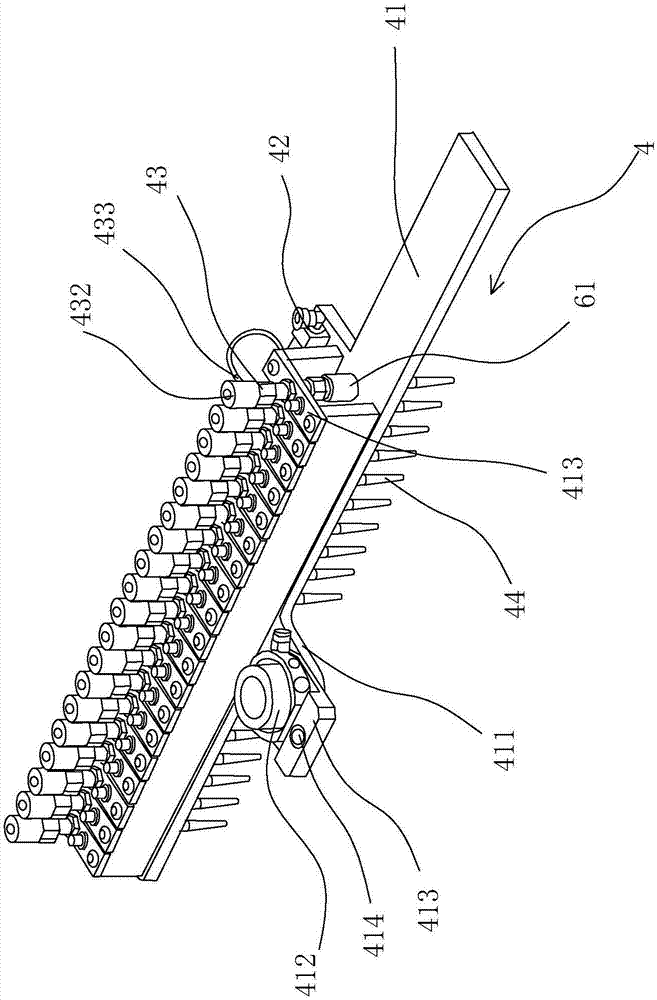

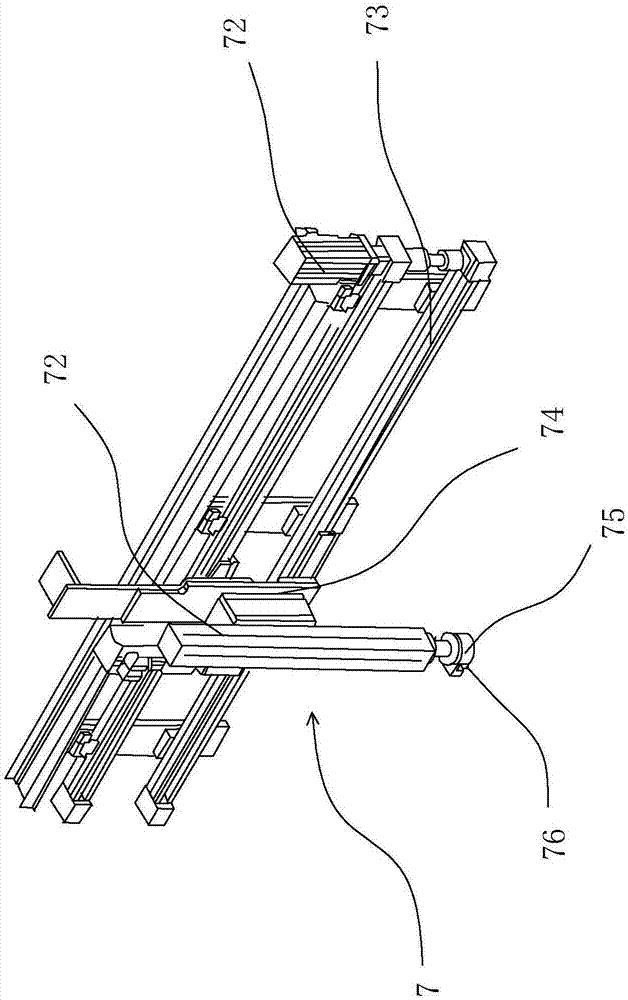

[0027] Such as figure 1 As shown, a blood collection tube automatic coating machine with an ultrasonic atomization mechanism includes a frame 1, which is characterized in that the frame 1 is provided with a first operating room 2 and a second operating room 3, the described The first operating room 2 and the second operating room 3 communicate with each other, and are provided with a nozzle assembly 4 for spraying the inner wall coating of the blood collection tube and a manipulator system 7 for moving the nozzle assembly 4, the first operating room 2 and the second operating room A coating fluid pump assembly 5 and an ultrasonic controller 6 are respectively arranged outside the two operation chambers 3 , and the output pipe 51 of the coating fluid pump assembly 5 passes through the ultrasonic controller 6 and is input to the nozzle assembly 4 .

[0028] A conveying device 8 is installed in the first operating room 2 and the second operating room 3 respectively, on which tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com