Porous indium oxide nanometer material and preparation method thereof

A technology of nanomaterials and indium oxide, which is applied in the field of nanomaterials, can solve the problems of complex template removal process, complicated preparation process, and low yield, and achieve the effect of uniform morphology, simple preparation method, and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a porous indium oxide nanomaterial, comprising the following steps:

[0029] (1) mixing indium salt, organic ligand, water and organic solvent to obtain a reaction solution;

[0030] (2) The reaction solution obtained in the step (1) is subjected to a hydrothermal reaction to obtain a porous indium oxide nanomaterial precursor;

[0031] (3) Calcining the porous indium oxide nanomaterial precursor obtained in the step (2) to obtain a porous indium oxide nanomaterial.

[0032] The invention mixes indium salt, organic ligand, water and organic solvent to obtain a reaction solution. In the present invention, the molar ratio of the indium salt, organic ligand, water and organic solvent is preferably 1:(1.5-10.5):(285-725):(350-850), more preferably 1:(3 ~8):(350~600):(400~800), most preferably 1:(4~6):(450~500):(500~700).

[0033] In the present invention, the indium salt preferably includes one or more of indium nitrate, indi...

Embodiment 1

[0047] Dissolve 0.2g of indium sulfate in 5mL of water, and dissolve 0.324g of dimethylimidazole in 25mL of DMF; mix the above two solutions, and ultrasonicate for 15min to obtain a reaction solution; the molar ratio of indium salt, organic ligand, water to solvent For: 1:10.2:720:837.

[0048] The reaction solution was added to a polytetrafluoroethylene reactor, and placed in a microwave reactor at 95°C for 5 minutes to obtain a precipitate; the precipitate was washed three times with DMF, centrifuged and dried in a vacuum oven at 120°C for 12 hours to obtain In 2 o 3 Precursor.

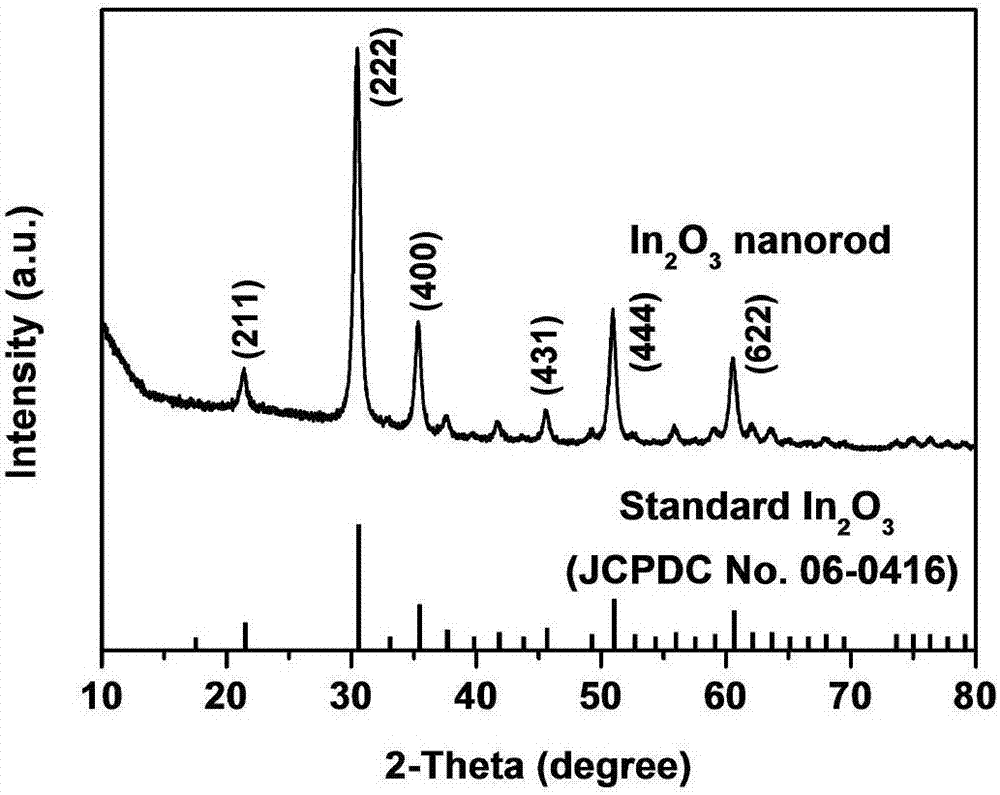

[0049] The above-mentioned precursor was calcined at 400°C for 1 hour, the heating rate was 1°C / min, and the temperature was naturally cooled to room temperature to obtain a gas-sensitive material. The sample was analyzed by XRD, and the results are shown in figure 1 . Depend on figure 1 It can be seen that the porous indium oxide nanomaterial prepared in this example is a cubic phase In 2 o 3...

Embodiment 2

[0052] Take 0.2g InCl 3 Dissolve in 5mL of water, take 0.25g of terephthalic acid and dissolve in 25mL of DMF; mix the above two solutions, and ultrasonicate for 15min to obtain a reaction solution; the molar ratio of indium salt, organic ligand, water and solvent is: 1:1.7 :307.2:357.4.

[0053] The reaction solution was added to a polytetrafluoroethylene reactor, and placed in a microwave reactor at 105°C for 10 minutes to obtain a precipitate; the precipitate was washed three times with DMF, centrifuged and dried in a vacuum oven at 150°C for 24 hours to obtain In 2 o 3 Precursor.

[0054] The above-mentioned precursor was calcined at 450° C. for 4 h, the heating rate was 1° C. / min, and the temperature was naturally lowered to room temperature to obtain a porous indium oxide nanomaterial.

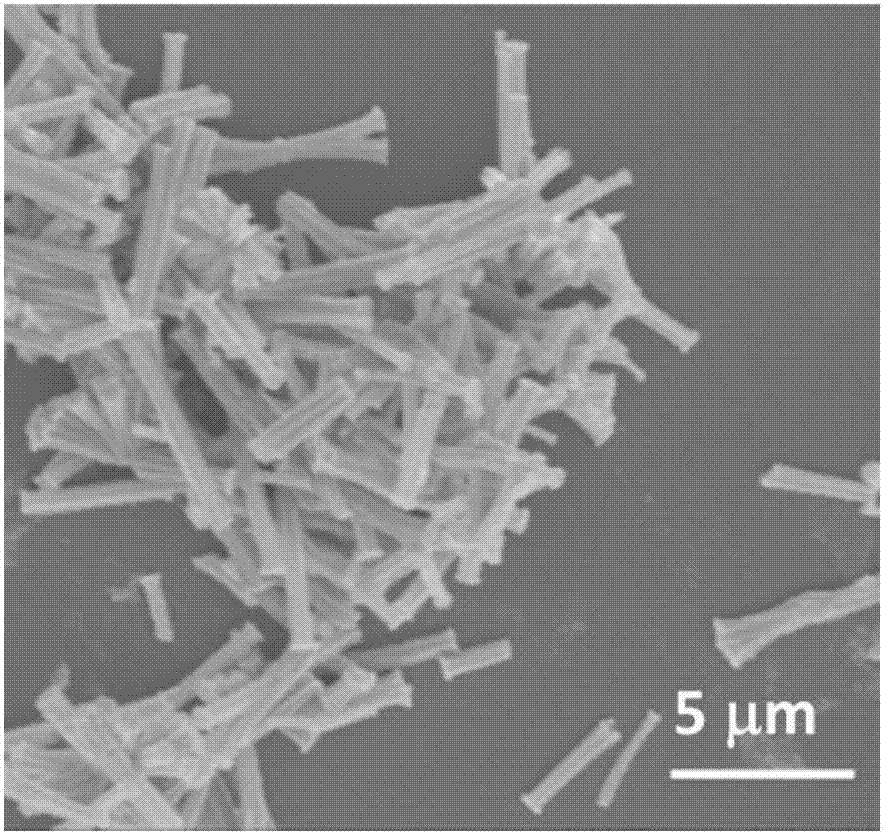

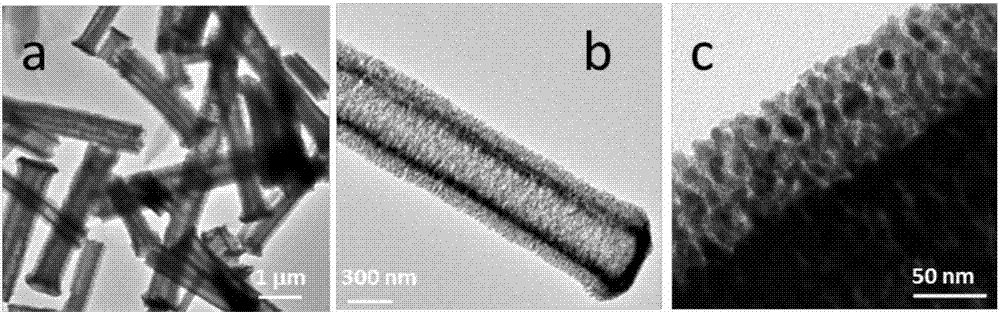

[0055] The scanning electron micrograph of the sample prepared in this embodiment is as follows: figure 2 as shown, figure 2 It shows that the obtained porous indium oxide nanomat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com