G-C3N4 nano-fiber antibacterial film and preparation method and application thereof

A technology of nanofibers and antibacterial membranes, applied in the field of preparation of g-C3N4 nanofiber antibacterial membranes, which can solve the problems of reducing the utilization rate of nanoparticles, easy aggregation and decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

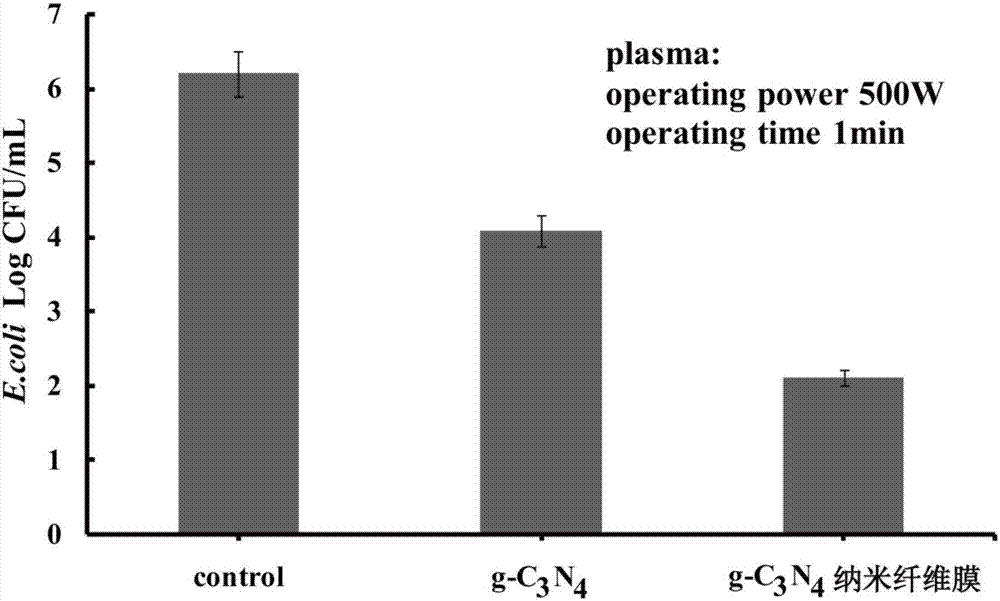

[0020] Example 1g-C 3 N 4 Antibacterial experiment of nanofiber antibacterial film against Escherichia coli

[0021] 1 Experimental materials

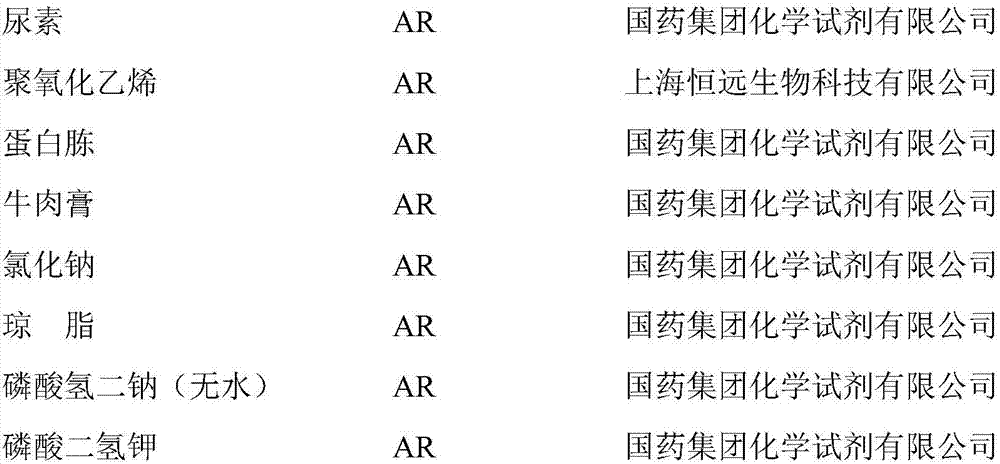

[0022]

[0023] 2 Experimental Standard Strains

[0024] Escherichia coli

[0025] 3 Experimental methods

[0026] 1) g-C 3 N 4 preparation of

[0027] ① Weigh 10g of urea, put it in a crucible, cover it, and put it in a vacuum tube furnace;

[0028] ②Adjust the calcination temperature and time: raise the temperature to 550°C at a rate of 5°C / min, then calcinate at 550°C for 4 hours, cool to room temperature, and obtain g-C as a light yellow solid 3 N 4 , ground into powder for later use.

[0029] 2) g-C 3 N 4 Preparation of nanofiber antibacterial film

[0030] ① According to the standard of mass volume concentration 0.5% (W / V, g / mL), g-C 3 N 4 The nanoparticles were added into a polyethylene oxide solution with a concentration of 10 wt% (g / g), and magnetically stirred for 24 hours to prepare a spinning precursor sol...

Embodiment 2

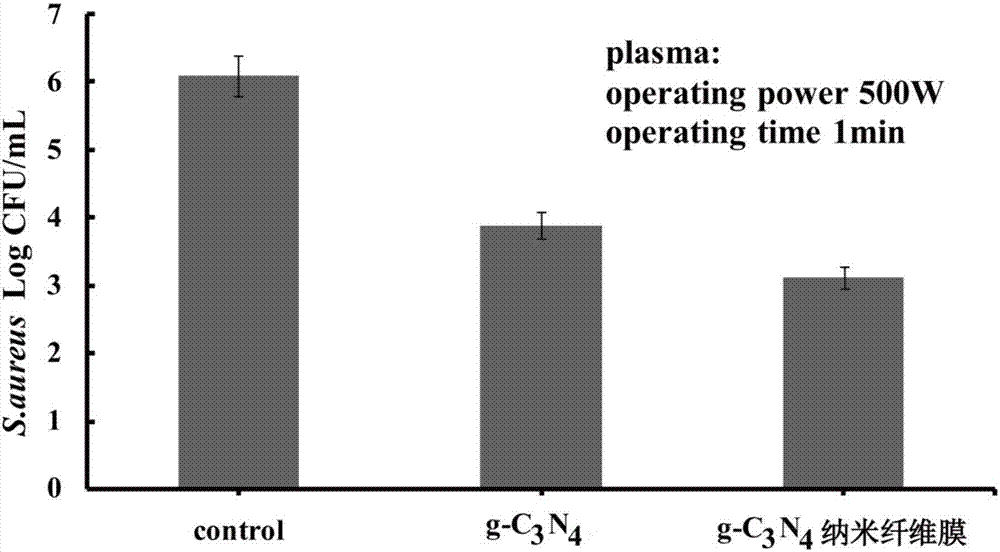

[0050] Example 2g-C 3 N 4 Antibacterial experiment of nanofiber antibacterial film against Staphylococcus aureus

[0051] 1 Experimental materials

[0052]

[0053] 2 Experimental Standard Strains

[0054] Staphylococcus aureus (S.aureus)

[0055] 3 Experimental methods

[0056] 1) g-C 3 N 4 preparation of

[0057] ① Weigh 10g of urea, put it in a crucible, cover it, and put it in a vacuum tube furnace;

[0058] ②Adjust the calcination temperature and time: raise the temperature to 550°C at a rate of 5°C / min, then calcinate at 550°C for 4 hours, cool to room temperature, and obtain g-C as a light yellow solid 3 N 4 , ground into powder for later use.

[0059] 2) g-C 3 N 4 Preparation of nanofiber antibacterial film

[0060] ① According to the standard of 0.5% (W / V, g / mL) in mass volume concentration, g-C 3 N 4 The nanoparticles were added into a polyethylene oxide solution with a concentration of 10 wt% (g / g), and magnetically stirred for 24 hours to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com