Assembly type lightweight hollow tube wall and construction method

A hollow-tube, prefabricated technology, applied in building structures, walls, building components, etc., can solve problems such as non-promotion, and achieve the effects of improving thermal insulation performance, blocking heat flow transfer, and facilitating industrial construction and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

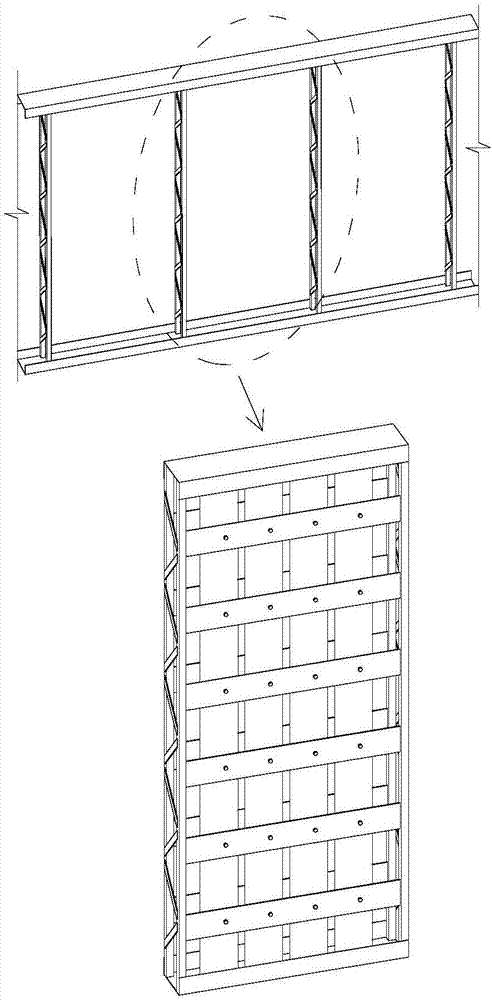

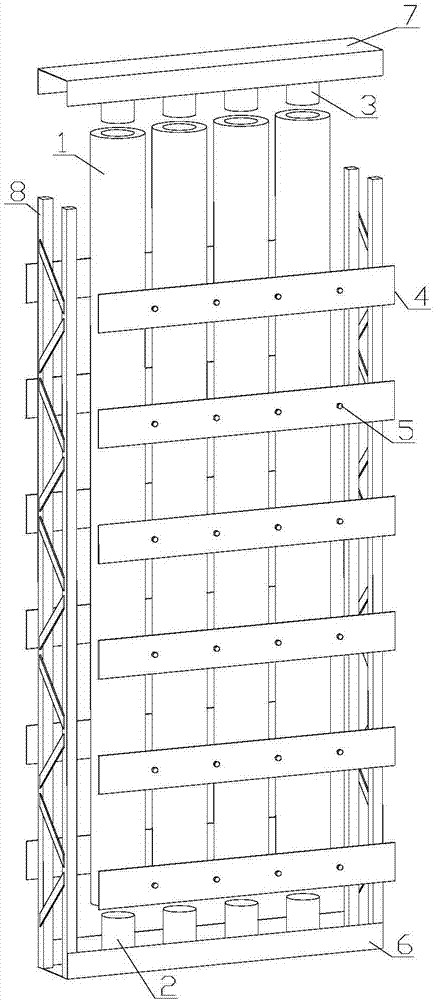

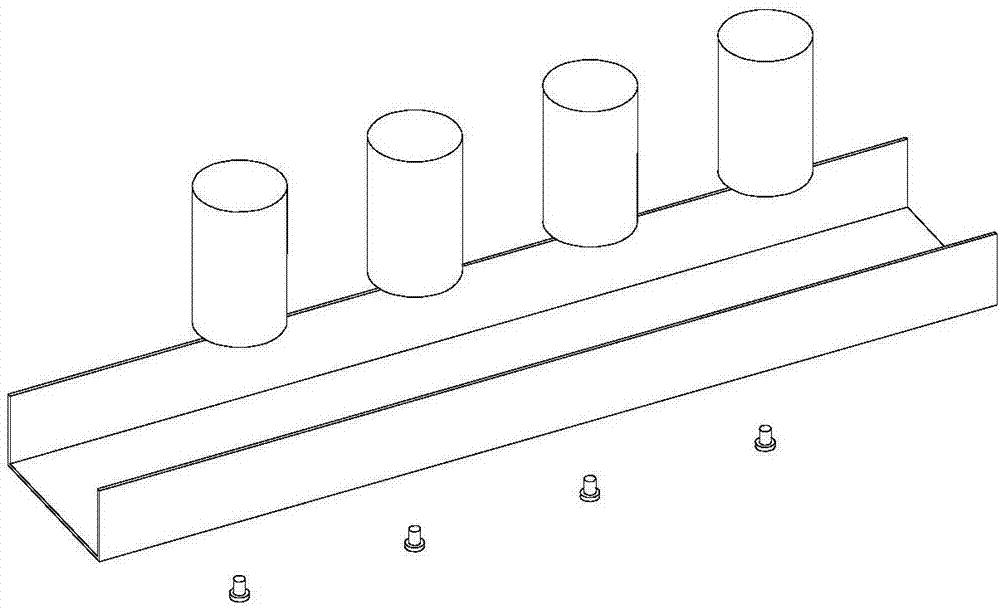

[0031] Such as figure 1 and figure 2 As shown, the assembled lightweight hollow tube wall of the present invention includes a plurality of incomparable steel columns 8, and hollow tube rows arranged in the same direction as the incomparable steel columns 8 are arranged between every two incomparable steel columns 8, and the hollow tubes The row includes a plurality of lightweight hollow tubes 1 arranged vertically. The lightweight hollow tubes 1 are made of lightweight hollow tube materials, including paper or plastic. The inner and outer walls of the lightweight hollow tubes 1 need to be coated with waterproof and a layer of fireproof material, and the slenderness ratio of the lightweight hollow tube 1 does not exceed 20; the upper vertical connector 3 and the lower vertical connector 2 are fixed with the hollow of the lightweight hollow tube...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap