Roof cutting and pressure releasing method for double-filling wall structure in gob-side entry retaining

A technology for roof cutting, pressure relief, and wall filling. It is applied in the directions of backfill, earthwork drilling, and bolt installation. It can solve problems such as harming the staff at the end, difficult to control the reaction time of the cracking agent, and affecting the construction of backfill walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention are further described below.

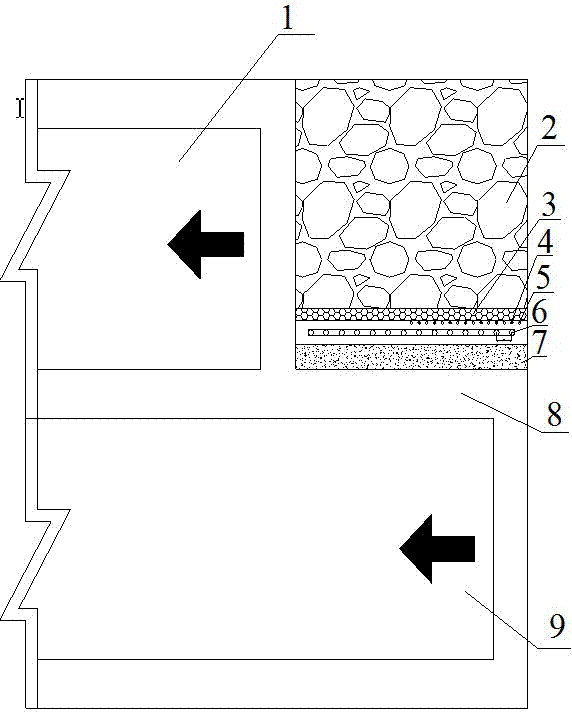

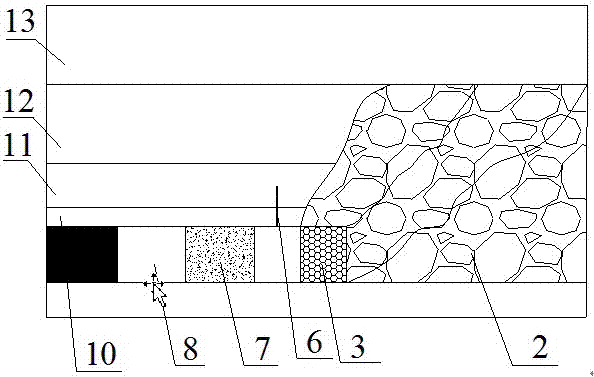

[0024] To implement the above-mentioned method of roof cutting and pressure relief for gobside entry retaining and double filling wall structure provided by the present invention is carried out according to the following steps:

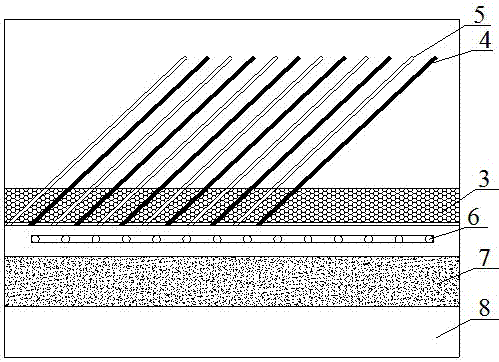

[0025] Step 1. Build the first high-water material filling wall 7

[0026] (1) The high-water material is composed of two components, material A and material B, wherein material A is Portland cement, retarder and suspending agent, and its mass ratio is 9:0.2:0.8; material B is gypsum , lime, accelerator and suspending agent, the mass ratio is 7:2.4:0.2:0.4; the retarder used is a mixture of citric acid, tartaric acid and their salts; the accelerator used is bauxite, Clinker mixture made of soda ash and quicklime; the suspending agent used in material A is a mixture of bentonite, cellulose ether and starch ether; the suspending agent used in material B is a mixture of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com