Steam pipe hydrophobic recovery system suitable for severe cold regions

A technology for steam pipelines and hydrophobic recovery, which is applied in the direction of pipeline protection, pipeline protection through heat insulation, steam traps, etc. It can solve the problems of unsatisfactory effects and low recovery efficiency, achieve low-cost installation, ensure no freezing, and save water resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

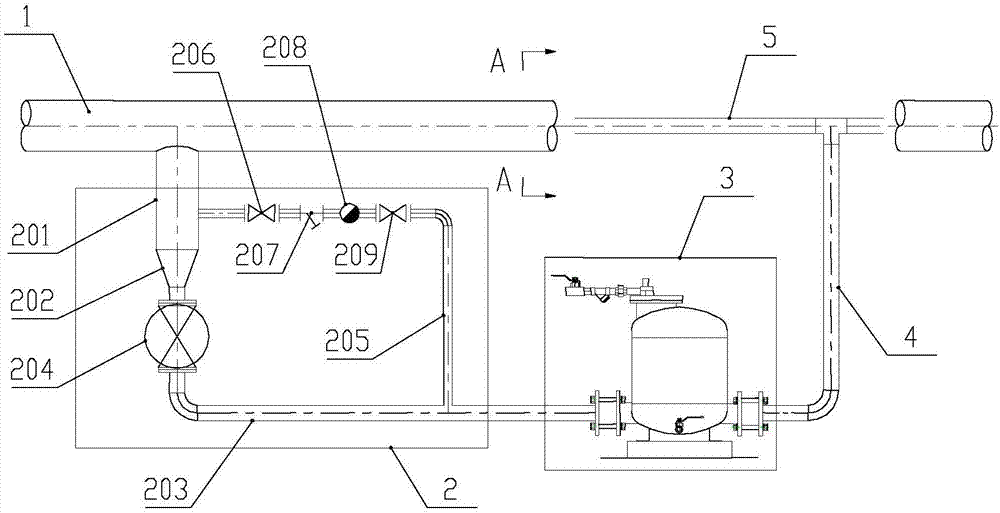

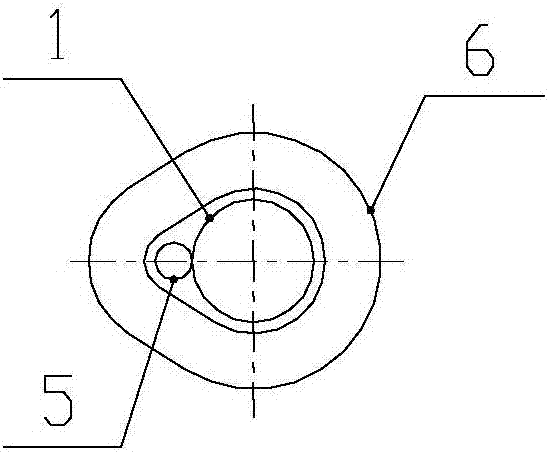

[0018] Such as figure 1 with figure 2 As shown, the present invention is a steam pipeline drainage recovery system suitable for severe cold regions, including several drainage recovery units connected to the steam pipeline 1 along the way, and the drainage recovery unit includes a steam trap group 2 connected to the steam pipeline 1 in turn , Condensed water recovery device 3 and condensed water pipeline 4; Wherein, each condensed water pipeline 4 is collectively connected with condensed water main pipe 5, and the condensed water main pipe 5 and steam pipe 1 are laid in the same heat preservation structure 6. The thermal insulation structure 6 includes a thermal insulation layer composed of thermal insulation rock wool, glass cloth and a protective layer composed of galvanized iron sheets of equal thickness stacked in sequence, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com