Automatic correction system free of machine head adjustment for full-automatic cable production line

An automatic calibration, production line technology, applied in cable/conductor manufacturing, insulation of conductors/cables, circuits, etc., can solve problems such as inability to adjust concentricity online, inability to adjust concentricity, etc., to reduce labor costs and processing costs, improve The effect of cable quality and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

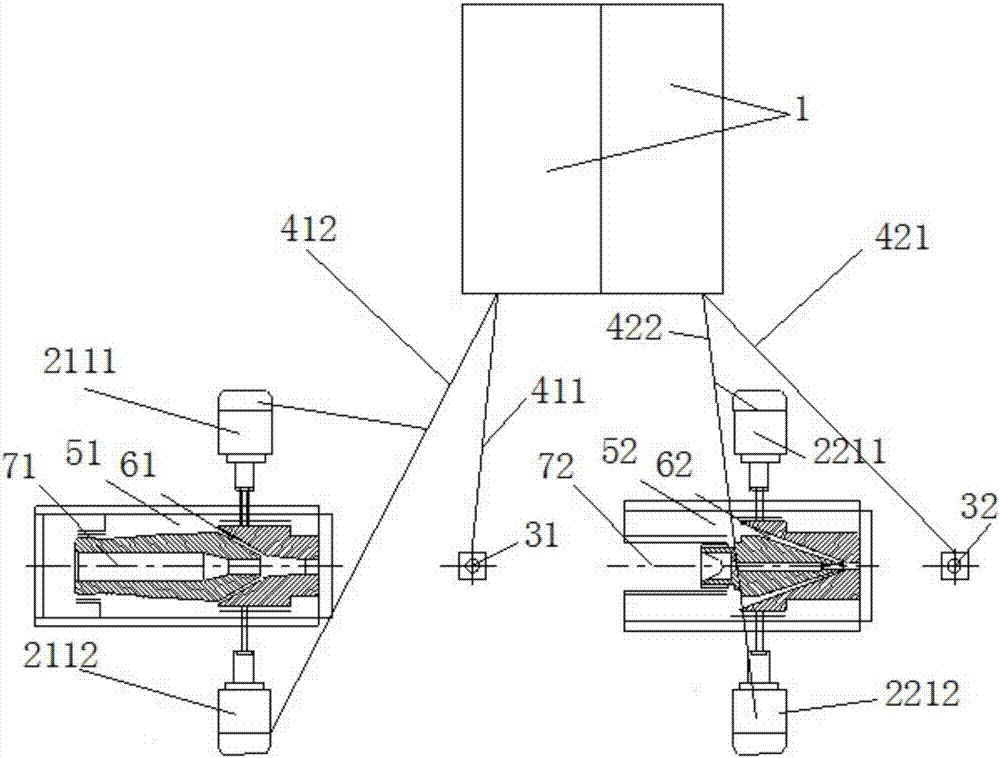

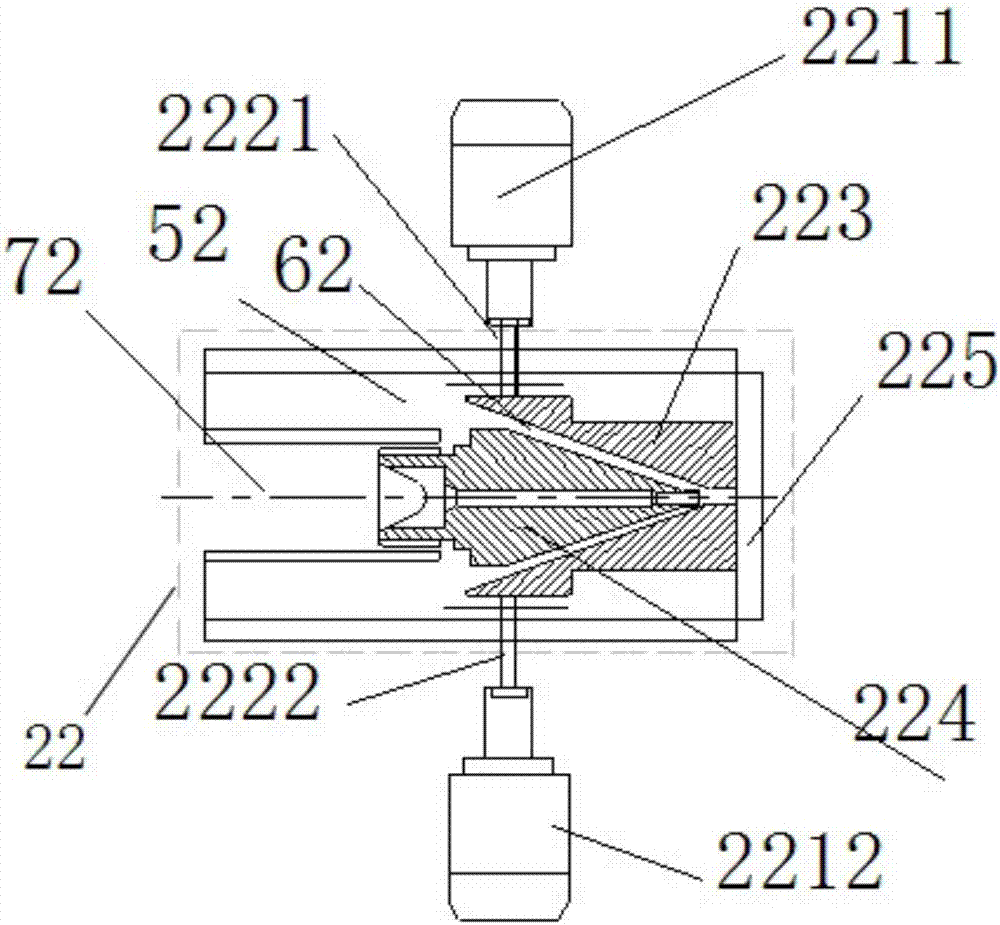

[0026] The automatic correction system without adjusting the machine head on the fully automatic cable production line disclosed by the present invention is as follows: figure 1 As shown, it includes: a subsystem for automatically correcting the coating extruder head 21 and a subsystem for automatically correcting the foam extruder head 22 .

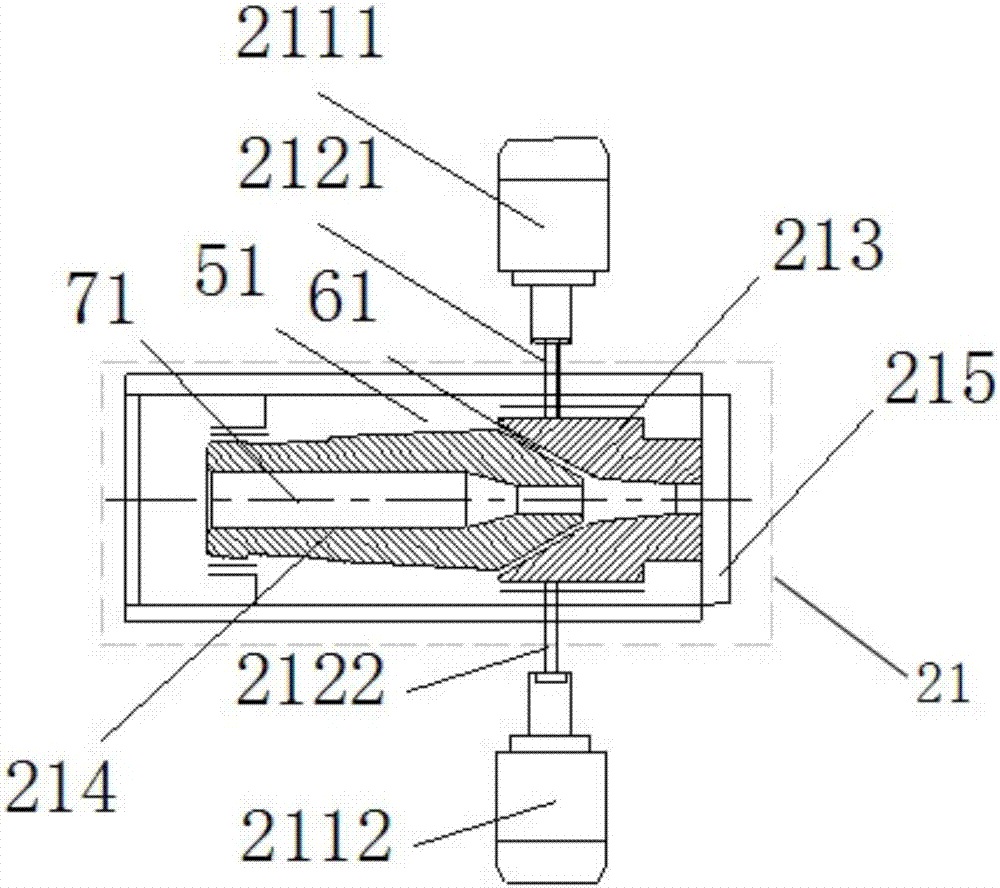

[0027] Automatic calibration of coating extrusion head 21 subsystems such as figure 1 , figure 2 As shown, it includes: a control unit 1, an actuator composed of coating servo motors 2111, 2112 and coating eccentric screws 2121, 2122, a detection unit that uses a coating eccentricity measuring instrument 31 to detect the concentricity of the coating insulation layer, coating measurement The data bus 411 and the coating execution data bus 412 form a feedback unit. The coating mold sleeve 213 fixed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com