Multifunction shafting testing device based on planetary gearing

A planetary transmission and test device technology, applied in the field of shaft vibration, can solve the problems of inability to measure torsional vibration and dynamic balance, and inability to conduct tests, etc., and achieve the effect of easy reorganization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

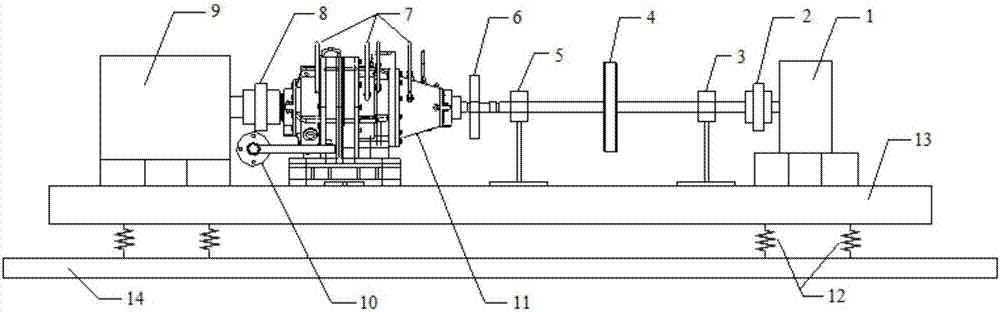

[0021] combine Figure 1-3 , The present invention includes: a test assembly, a vibration isolator 12, a stand 13, and a base 14.

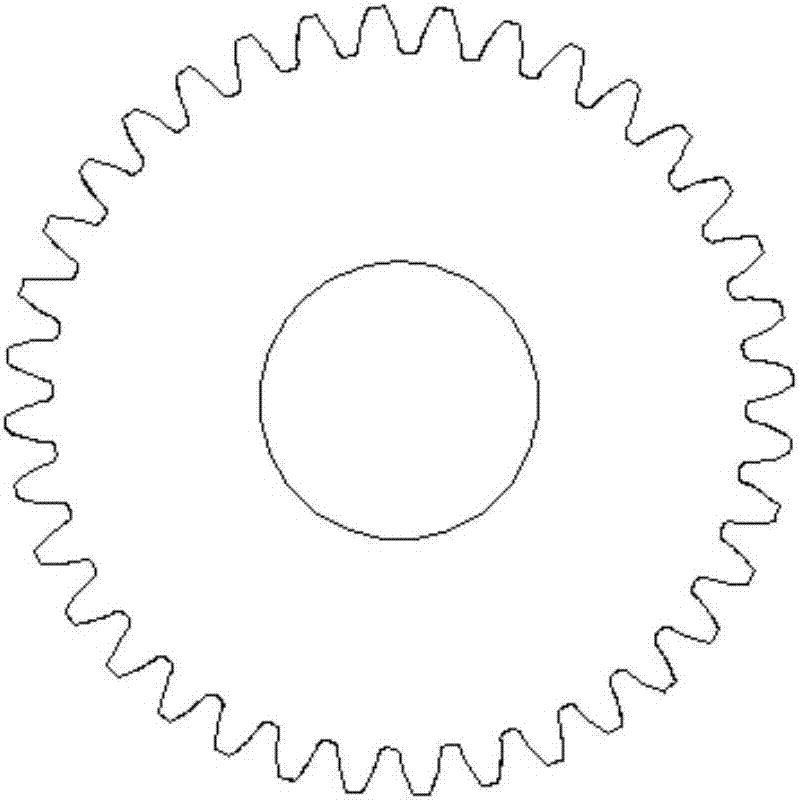

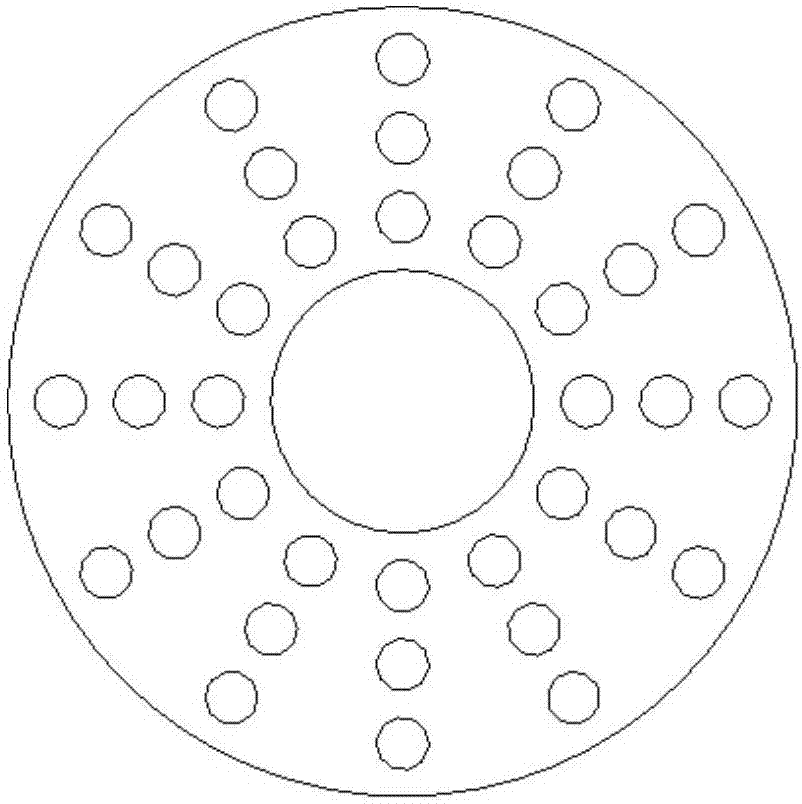

[0022] The test components include: drive motor 1, input coupling 2, dynamic balance test disc 4, sliding coupling 5, torsional vibration test tooth disc 6, test load, first rotating shaft, second rotating shaft; the test components are installed in On the stand 13 , a vibration isolator 12 is installed between the stand 13 and the base 14 .

[0023] In the adopted technical solution, the test load includes a planetary gear reducer 11, an output coupling 8, and a load generator 9, and the output coupling 8 is installed between the planetary gear reducer 11 and the load generator 9 through a rotating shaft. .

[0024] The test components include: drive motor 1, input coupling 2, sliding bearing 3, dynamic balance test disc 4, slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com