High-voltage explosion-proof three-phase asynchronous motor for coal mine belt conveyor

A belt conveyor, three-phase asynchronous technology, applied in the field of electric motors, can solve the problems of frequent heavy-load starting of belt conveyor motors, unbalanced motor power, etc., to avoid frequent alarm shutdown or motor burnout, and reduce startup temperature rise. , the effect of increasing the maximum torque multiple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

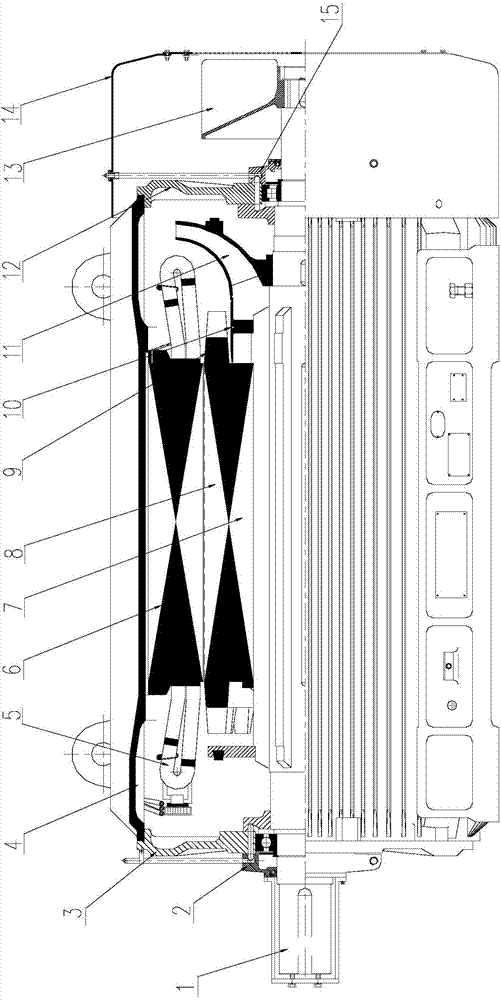

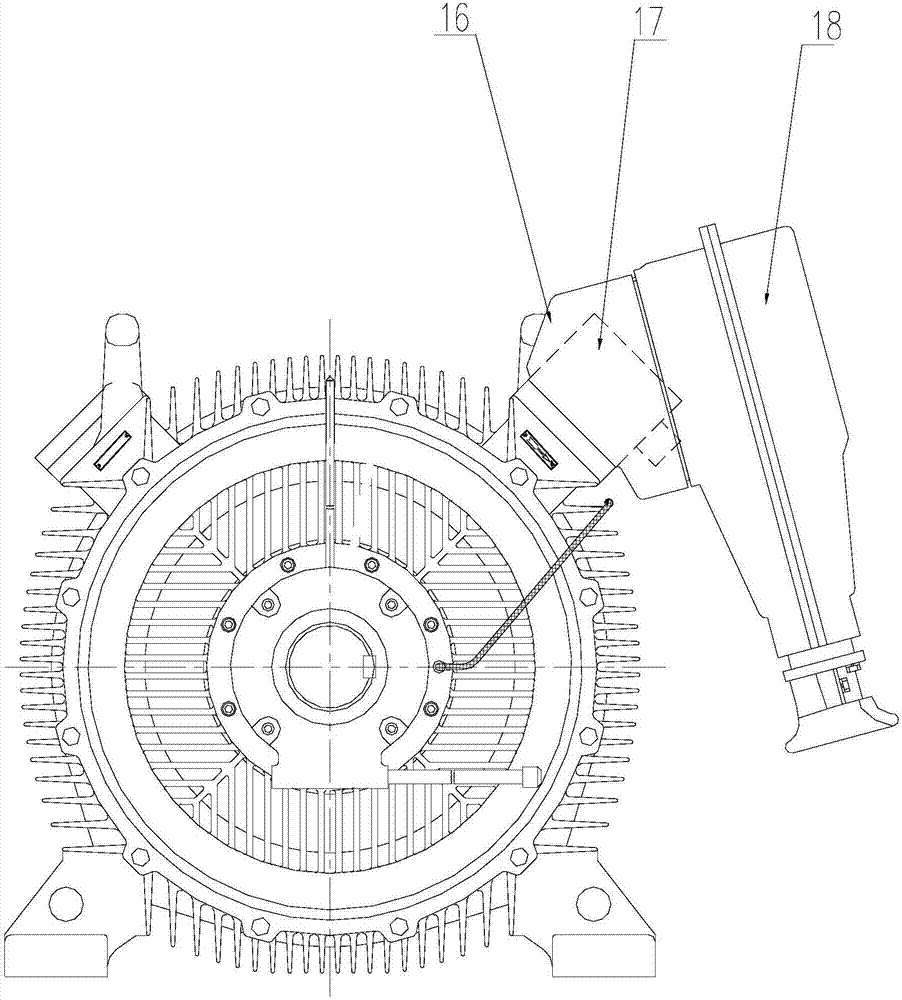

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 As shown in the figure: the high-voltage flameproof three-phase asynchronous motor for coal mine belt conveyor in this embodiment includes a stator, a rotor, and a cooling device; the stator includes a base 4 and is arranged inside the base 4 The stator core with windings; the rotor includes a shaft 1 and a squirrel cage rotor arranged on the shaft 1, one end of the shaft 1 protrudes out of the machine base 4 to form a shaft extension end, and the other end is located in the end cover 14 of the machine base 4 A non-shaft extension end is formed, and the shaft extension end and the non-shaft extension end are respectively supported in the stator through the end cover assembly; The fan 11 is located in the base 4 and fixed on the shaft 1, the air guide tube 10 communicates with the inner fan 11, the outer fan 13 is located in the end cover 14, and is fixed on the non-extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com