Preparation method of vertically oriented graphene-based material

A graphene-based, vertically oriented technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of harsh conditions and high equipment requirements, achieve enhanced electrical properties, simple preparation process and experimental equipment, and facilitate large-scale The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 60 mg of graphene oxide (GO) was dissolved in 30 mL of deionized water to form a 2 mg / mL GO solution. Take a 1ml sample of the prepared 2mg / ml graphene oxide solution, and use a sand core suction filter device to prepare a graphene oxide film with an area of 1*1cm 2 , a graphene oxide film with a mass of 2 mg. The film was quickly frozen in liquid nitrogen, and then dried in a freeze dryer for 12 hours to obtain a vertically oriented graphene oxide material.

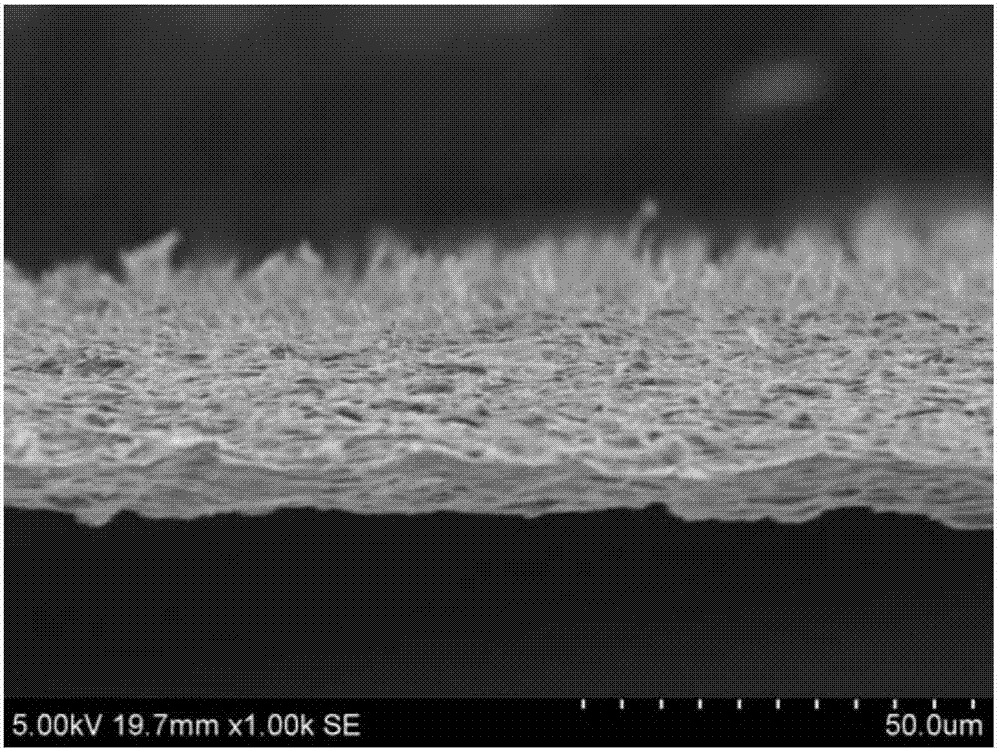

[0021] Morphological characterization of graphene oxide materials, the results are as follows figure 1 shown. The resistance measured by the four-probe method is shown in Table 1.

Embodiment 2

[0023] 60 mg of graphene was dissolved in 30 mL of deionized water to form a GO solution with a concentration of 2 mg / mL. Take a 1ml sample of the prepared 2mg / ml graphene solution, and use a sand core suction filter device to prepare a graphene film with an area of 1*1cm 2 , a graphene film with a mass of 2 mg. The film was quickly frozen in dry ice, and then dried in a freeze dryer for 12 hours to obtain a vertically oriented graphene material.

Embodiment 3

[0025] A homogeneous solution of CRGO with a concentration of 2 mg / mL was prepared by dispersing chemically reduced graphene oxide (CRGO) in ultrapure water. Take a 1ml sample of the prepared 2mg / ml CRGO solution, and use a sand core suction filter device to prepare a CRGO film with an area of 1*1cm 2 , a film of CRGO with a mass of 2 mg. Put the film into liquid nitrogen for rapid freezing, take it out and dry it in a freeze dryer for 12 hours to obtain a vertically oriented chemically reduced graphene oxide material. The resistance measured by the four-probe method is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com