Method for preparing Camellia oleifera seed oil by near-solid enzymatic hydrolysis combined with physical pressing

Camellia oleifera seed oil, a near-solid-state technology, is applied in the direction of fat oil/fat production and fat production, which can solve the problems of strict process parameters, immature development of supporting equipment, and few production applications, so as to achieve good quality, save resources, and improve The effect of pressing oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

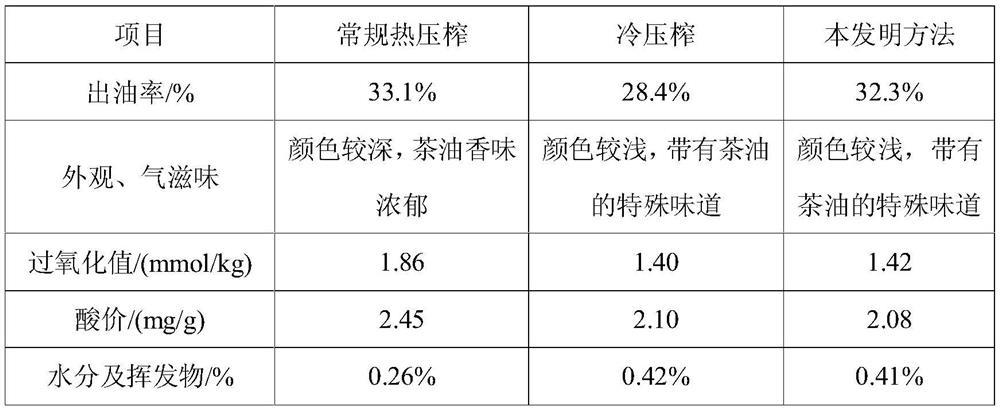

[0019] The method of the invention is compared with the oil yield and oil products of conventional hot pressing and cold pressing.

[0020] 1. Test method

[0021] 1.1 Test raw materials

[0022] Camellia oleifera seeds are provided by Xiangxi Shanchajing Health Technology Co., Ltd. The oil content of tea seed kernels is 39.4% after testing.

[0023] 1.2 Process parameters

[0024] Conventional hot pressing process: oil tea seeds are picked, dried, shelled, shelled, and magnetically separated, and then steamed and fried at high temperature with a drum seed frying machine. The control process conditions are that the temperature of the seeds is 120-140°C, and the time is 20-40min. , control the water content of the camellia seed output to be below 4%, and then use the LZY126-2L high-efficiency twin-screw press for pressing, and control the pressing temperature at 100-110°C.

[0025] Cold pressing process: Camellia oleifera seeds are picked, dried, dehulled, dehulled, and magn...

Embodiment 2

[0036] A method for producing camellia oleifera seed oil by combining near-solid-state enzymatic hydrolysis with physical pressing, comprising the steps of tea seed picking, drying, shelling, seed-husk removal, magnetic separation, oil extraction, and refining. The method of physical pressing, specifically:

[0037] (1) Near-solid-state enzymatic hydrolysis: crush the tea seed kernels to 10-20 mesh, add solid-state enzymes and mix well with the tea seed kernels, then carry out constant temperature stirring for enzymatic hydrolysis, and spray on the surface of the tea seed kernels in the form of spray during the stirring process Clean water, always control the moisture content of the tea seed kernel to less than 18%, and dry at low temperature after enzymatic hydrolysis until the moisture content of the tea seed kernel is 10-13%;

[0038] (2) Physical pressing: pressing the Camellia oleifera seeds after solid-state enzymatic hydrolysis.

Embodiment 3

[0040] A method for producing camellia oleifera seed oil by combining near-solid-state enzymatic hydrolysis with physical pressing, comprising the steps of tea seed picking, drying, shelling, seed-husk removal, magnetic separation, oil extraction, and refining. The method of physical pressing, specifically:

[0041] (1) Near-solid-state enzymatic hydrolysis: crush the tea seed kernels to 10-20 mesh, add solid-state enzymes and mix well with the tea seed kernels, then carry out constant temperature stirring for enzymatic hydrolysis, and spray on the surface of the tea seed kernels in the form of spray during the stirring process Clean water, always control the moisture content of the tea seed kernel to be lower than 18%, and dry at low temperature after enzymolysis until the moisture content of the tea seed kernel is 10-13%; wherein, the solid enzyme is composed of the following substances in parts by weight: cellulase 0 -10 parts, 0-40 parts of protease, 0-10 parts of pectinas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com