Ecological and environment-friendly methane tank

A biogas digester, an environmentally friendly technology, applied in biochemical instruments, biomass post-treatment, biological sludge treatment, etc., can solve problems such as low fermentation efficiency, incomplete fermentation, and interruption of biogas supply, so as to improve fermentation efficiency and agitation and blending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

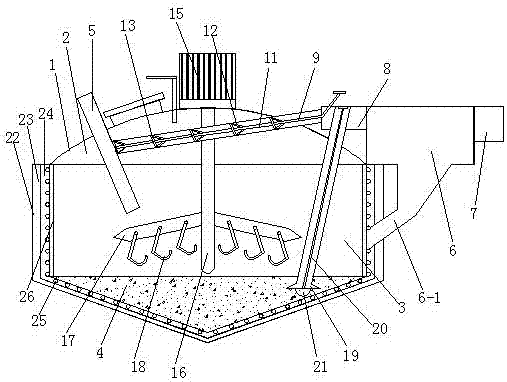

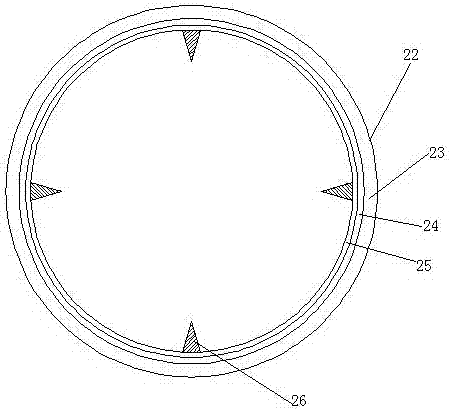

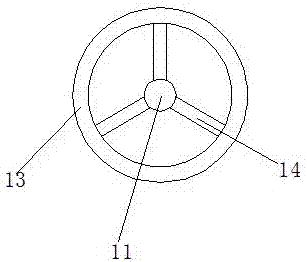

[0025] Refer to attached Figure 1-3 Shown is an eco-environmental protection type biogas digester. The biogas digester 1 includes a gas storage chamber 2, a fermentation chamber 3 and a bottom material chamber 4 from top to bottom. The bottom of the biogas digester 1 is a triangular pyramid structure. There is an air guide pipe 1-1 and a movable cover. The biogas tank 1 is provided with a feed pipe 5 and a water pressure room 6 on the outside. The water pressure room 6 and the biogas tank 1 are connected through an inclined pipe 6-1. The setting of the water pressure room 6 can improve the heat preservation of the fermentation room. At the same time, because the water pressure room 6 and the fermentation tank are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com