Camshaft manufacturing method and camshaft

A production method and camshaft technology, which are applied in valve details, mechanical equipment, valve devices, etc., can solve the problems affecting the overall strength and reliability of the assembled camshaft, low assembly efficiency, and low qualified rate of finished products, and achieve product quality. Lighten, reduce cycle time, create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

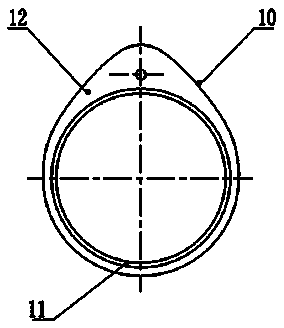

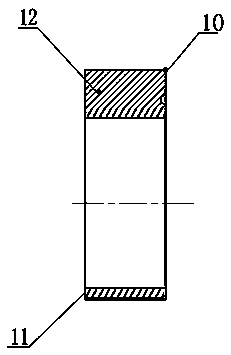

[0045] Please refer to image 3 and Figure 4 , a preparation method of an overhead camshaft 7, comprising the steps of:

[0046] 1. Prepare the material for the inner layer 11. The inner layer is composed of the following components: 1 part of C, 1999 parts of Fe; the particle size of the material is 0.1 μm, and the material is mixed through a mixing equipment, and the precisely weighed mixed material is poured Put it into a special mold for leveling;

[0047] 2. Under the pressure of 500MPa, the inner layer 11 material is pressed into the inner layer blank corresponding to the shape of the cam piece, that is, the inner ring blank;

[0048] 3. Vacuum sinter the inner blank in a vacuum furnace. The sintering temperature in the sintering furnace is 800°C for 30 minutes. After cooling in the vacuum furnace, the inner blank is sintered and formed;

[0049] 4. Prepare the outer layer 12 materials. The outer layer is composed of the following components: 2 parts of C, 198 parts ...

Embodiment 2

[0066] Please refer to Figure 3 to Figure 4 , a preparation method of an overhead camshaft 7: comprising the steps of:

[0067] 1, prepare above-mentioned inner layer 11 materials, described inner layer is made up of following components: 5 parts of C, 20 parts of Cu, 10 parts of Mo, 50 parts of Cr, 10 parts of Ni, 5 parts of Si, 1700 parts of Fe, the material The particle size is 200μm, and the mixture is mixed through the mixing equipment, and the precisely weighed mixture is poured into a special mold for leveling;

[0068] 2. Under the pressure of 1200MPa, the inner layer 11 material is pressed into the inner layer blank corresponding to the shape of the cam piece, that is, the inner ring blank;

[0069] 3. Vacuum sinter the inner layer blank in a vacuum furnace. The sintering temperature in the sintering furnace is 1250°C for 120 minutes. After cooling in the vacuum furnace, the inner layer blank is sintered and formed;

[0070] 4. Prepare the above-mentioned outer lay...

Embodiment 3

[0087] Please refer to image 3 and Figure 4 , a preparation method of an overhead camshaft 7: comprising the steps of:

[0088] 1. Prepare the above 11 inner layer materials, 8 parts of C, 50 parts of Cu, 19 parts of Mo, 70 parts of Cr, 20 parts of Ni, 4 parts of Si, 1750 parts of Fe; Mixing, pour the precisely weighed mixture into a special mold for leveling;

[0089] 2. Under the pressure of 850MPa, the inner layer material is pressed into the inner layer blank corresponding to the shape of the cam piece, that is, the inner ring blank;

[0090] 3. Vacuum sinter the inner layer blank in a vacuum furnace. The sintering temperature in the sintering furnace is 1000°C for 100 minutes. After cooling in the vacuum furnace, the inner layer blank is sintered and formed;

[0091] 4. Prepare the above-mentioned outer layer 12 materials, the outer layer is composed of the following components: 4 parts of C, 2 parts of Cu, 1.6 parts of Mo, 10 parts of Cr, 2 parts of Ni, 0.7 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com