Silicone elastomer for sealing, and preparation method and application thereof

A technology of silicone elastomers and elastomers, applied in chemical instruments and methods, other chemical processes, adhesives, etc., can solve problems such as insufficient hardness, insufficient strength, and low effect, and achieve good strength and high flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

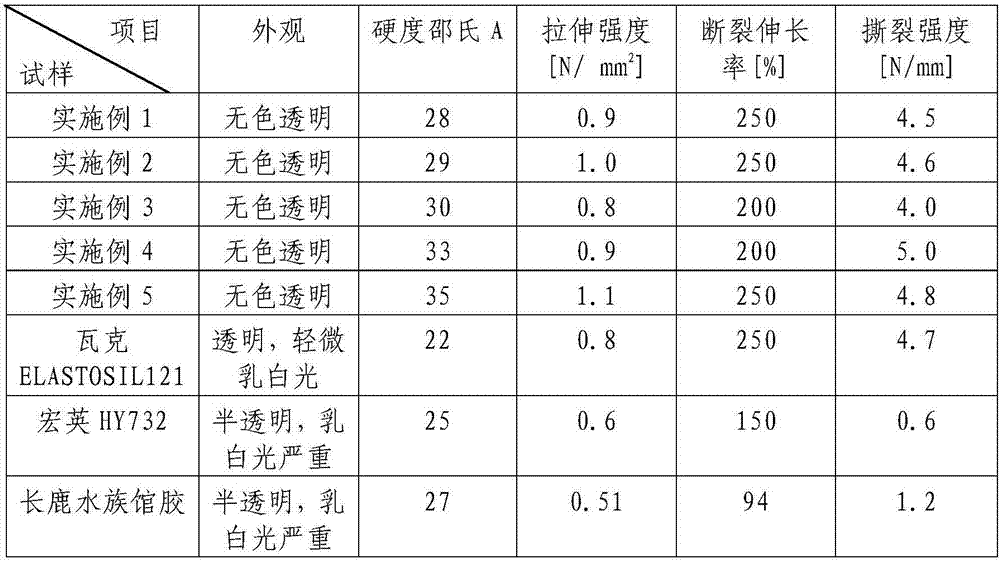

Examples

Embodiment 1

[0033] This embodiment relates to a silicone elastomer used for sealing, and its preparation method comprises the following steps:

[0034] 1) Add 100g of methyltrichlorosilane, 50g of phenyltrichlorosilane, 800g of dimethyldichlorosilane, and 800g of toluene into a 3000ml three-necked flask;

[0035] 2) Slowly add 100g of deionized water dropwise under the condition of temperature control at 10°C and stirring. After the dropwise addition, maintain the temperature and stir, and react for 2 hours;

[0036] 3) Separating the lower layer of acidic water, washing the organic layer repeatedly to neutrality, removing the toluene solvent at 120°C, cooling the system to room temperature, and obtaining a transparent viscous paste;

[0037] 4) Take 300g of the above paste, add 3g polyether modified silicone oil, 1g200mm 2 / s of simethicone oil, 0.03g of acrylonitrile, 0.45g of butyl titanate, and 15 parts of methyltriacetoxysilane were added under nitrogen and moisture barrier conditio...

Embodiment 2

[0039] This embodiment relates to a silicone elastomer used for sealing, and its preparation method comprises the following steps:

[0040] 1) Add 180g of methyltrichlorosilane, 100g of phenyltrichlorosilane, 1500g of dimethyldichlorosilane, and 1500g of toluene into a 5000ml three-necked flask;

[0041] 2) Slowly add 500g of deionized water dropwise under the condition of temperature control at 0°C and stirring. After the dropwise addition, maintain the temperature and stir, and react for 2 hours;

[0042] 3) Separating the lower layer of acidic water, washing the organic layer repeatedly to neutrality, removing the toluene solvent at 120°C, cooling the system to room temperature, and obtaining a transparent viscous paste;

[0043] 4) Take 300g of the above paste, add 3g of polyether modified silicone oil, 0.03g of cyclohexanone oxime, 0.45g of dibutyltin dilaurate, and add 15 parts of methyltriacetoxy Silane, mixed to obtain silicone elastomer.

Embodiment 3

[0045] This embodiment relates to a silicone elastomer used for sealing, and its preparation method comprises the following steps:

[0046]1) Add 150g of methyltrichlorosilane, 70g of phenyltrichlorosilane, 800g of dimethyldichlorosilane, 10g of methylphenyldichlorosilane, and 830g of xylene into a 3000ml three-necked flask;

[0047] 2) Slowly add 200g of deionized water dropwise under the condition of temperature control at 20°C and stirring. After the dropwise addition, maintain the temperature and stir, and react for 1.5 hours;

[0048] 3) Separating the lower layer of acidic water, washing the organic layer repeatedly to neutrality, removing the xylene solvent at 140°C, cooling the system to room temperature, and obtaining a transparent viscous paste;

[0049] 4) Take 300g of the above paste, add 3g polyether modified silicone oil, 10g 500mm 2 / s of simethicone oil, 0.03g tetraalkylthiuran disulfide, 0.4g dibutyl tin dioctoate, add 5 parts of ethyl triacetoxysilane under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com