Four-way hydraulic transformer with variable flow-distribution waist-type holes and equal flow discharge of inlet and outlet oil

A four-way hydraulic and waist-shaped hole technology, which is applied in fluid pressure converters, mechanical equipment, etc., can solve the problems of throttling and heating, large volume and weight, and low recovery efficiency, so as to improve control accuracy, large volume and weight , the effect of low recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

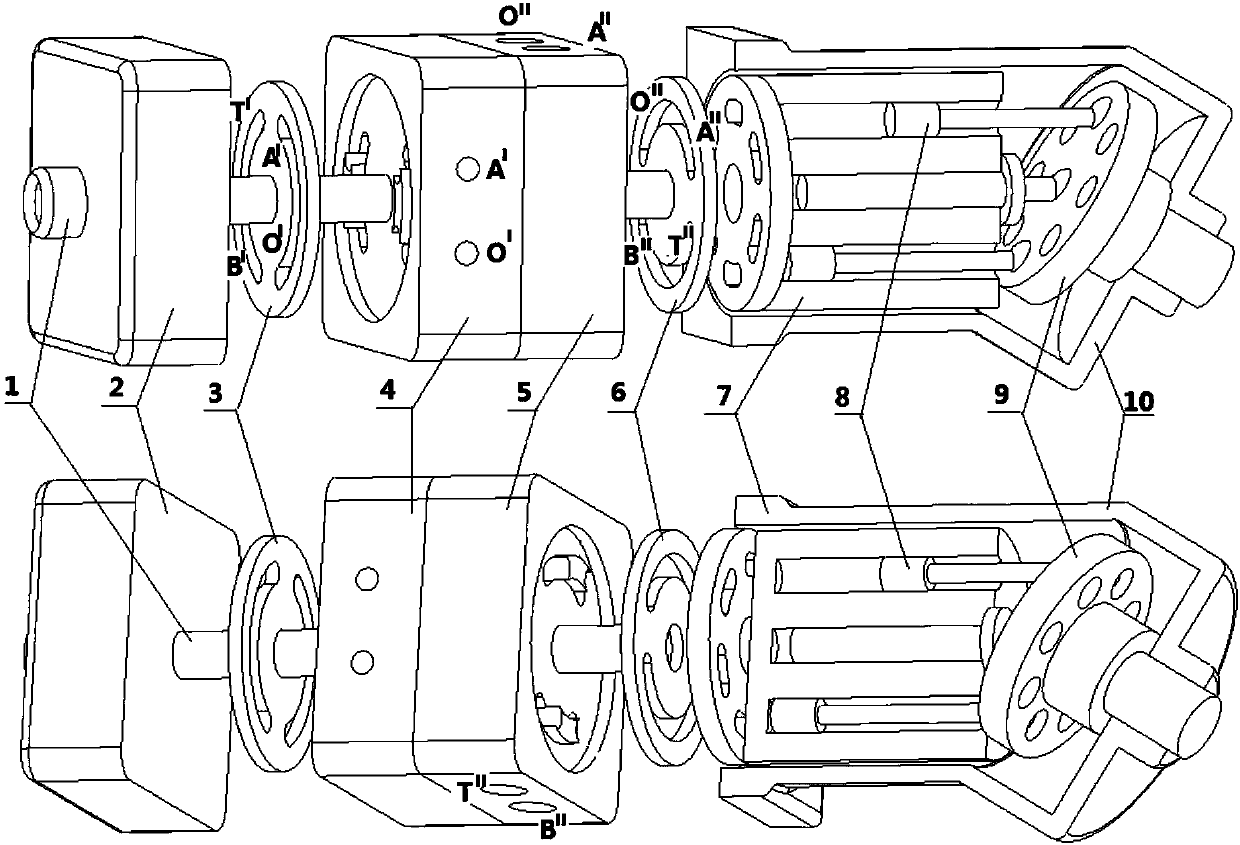

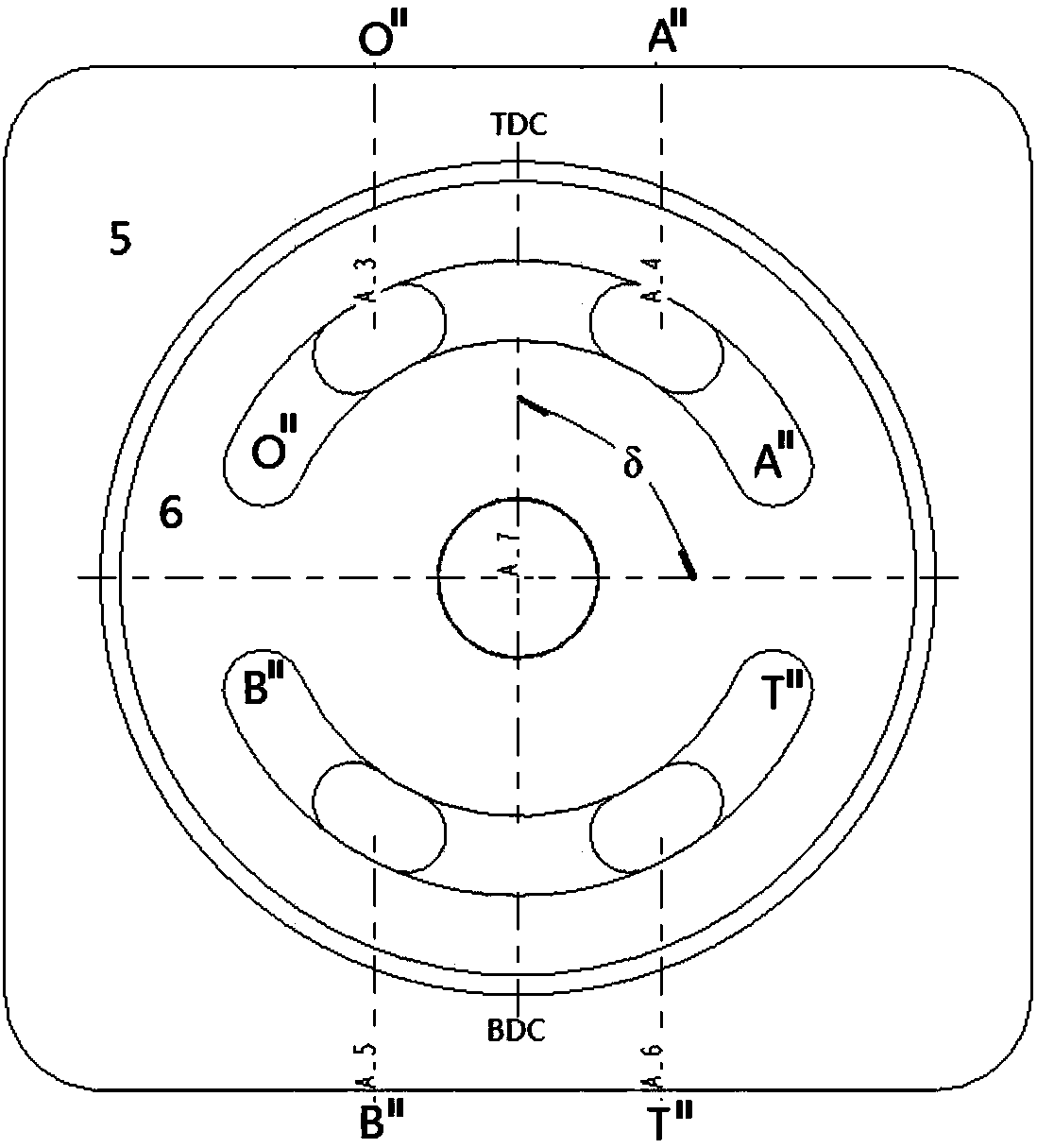

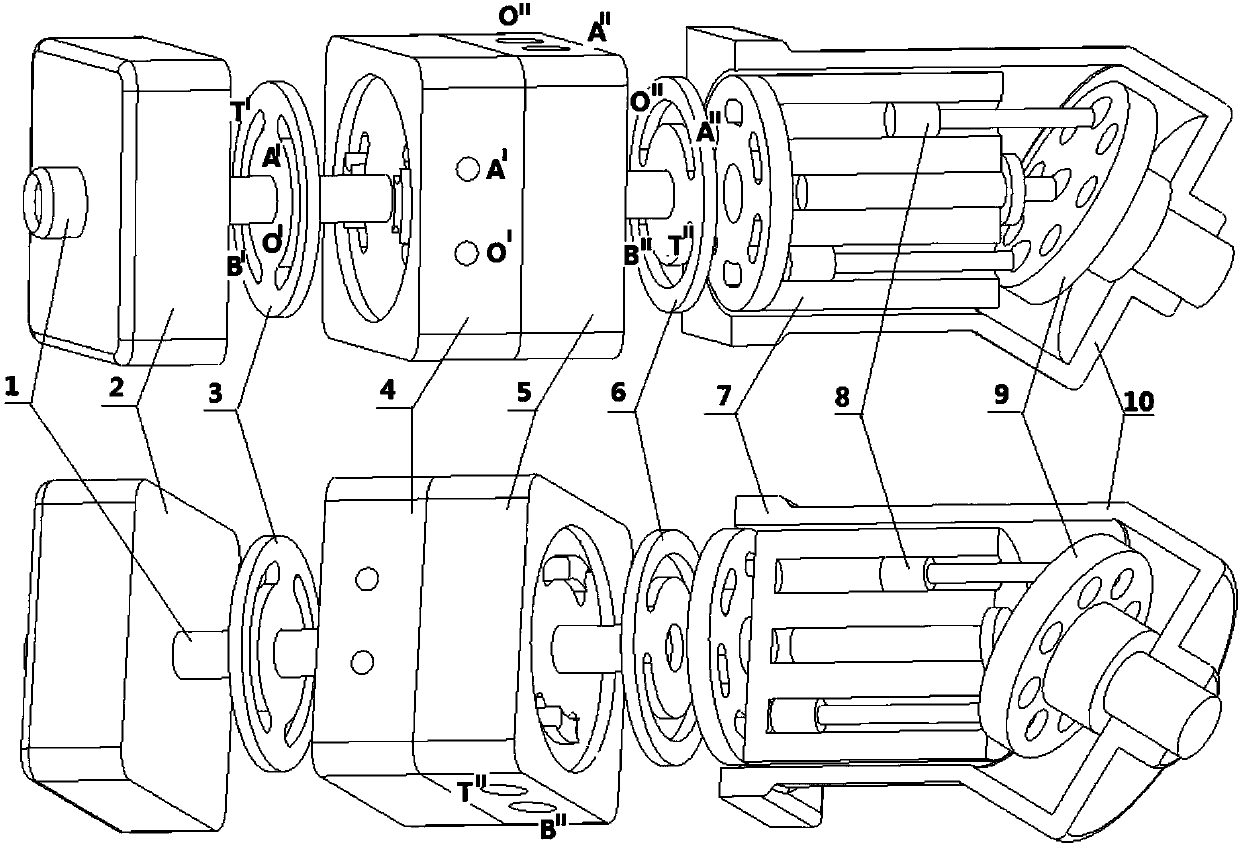

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] In the hydraulic transformer of the present invention, the two upper waist-shaped holes on the main distribution plate 6 are separated into four distribution waist-shaped holes by two fixed distribution isolation blocks on the distribution cover 5. When the main distribution plate 6 rotates, the four distribution holes The length of the waist-shaped hole is variable, and the distribution waist-shaped hole will not cross the dead point. When the plunger 8 passes through a distribution waist-shaped hole, it can only absorb or discharge oil. This structure makes the rotation range of the main distribution plate 6 theoretically It can reach 180 degrees, the resolution of the transformation ratio is large, and the control accuracy is high; the use of this hydraulic transformer can greatly reduce the loss of hydraulic energy, improve system efficiency, reduce system he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com